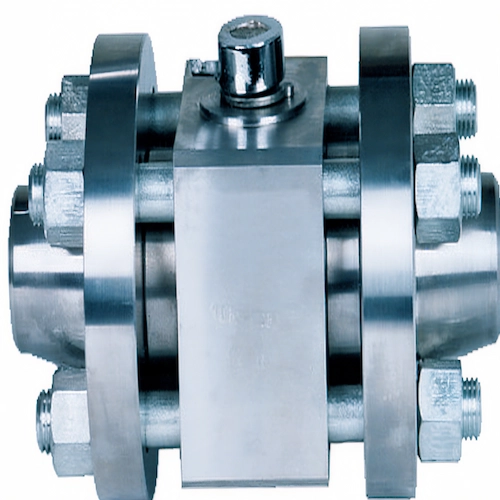

3-Piece Construction Welding Ball Valve

The 3-Piece Construction Welding Ball Valve (Forging) is designed for high-performance applications that require reliability and superior sealing. With a unique three-piece construction and forged components, this valve provides an enhanced sealing effect, high durability, and leak prevention, even in the most demanding environments.

This valve is ideal for industries such as oil and gas, chemical processing, water treatment, and power generation, where high-pressure and high-temperature fluid control is crucial. It provides robust performance with an easy installation process and the option for welding directly into the pipeline.

Key Features:

-

Three-Piece Design: Provides a compact, secure, and robust solution for fluid flow control, especially in high-pressure applications.

-

Forged Components: All components are forged to ensure high strength, durability, and reliable performance over long periods.

-

Advanced Sealing Technology: The valve is designed with a backwards sealing structure for enhanced sealing and protection against leakage.

-

Wide Pressure Range: Designed to handle pressures from 16 MPa up to 32 MPa, making it suitable for most heavy-duty applications.

-

Temperature Resistance: Capable of operating in temperature ranges from -40°C to 80°C, ensuring flexibility across a variety of environments.

Technical Specifications

| Component | Specification |

|---|---|

| Nominal Diameter (DN) | 15 – 200 mm |

| Nominal Pressure (PN) | 16 MPa, 32 MPa |

| Strength Test Pressure | 24 MPa, 48 MPa |

| Low Pressure Sealing Test | 0.6 MPa |

| High Pressure Sealing Test | 17.6 MPa, 35.2 MPa |

| Applicable Medium | Water, Oil, Steam |

| Applicable Temperature | -40°C to 80°C |

| Materials | WCB, 1Cr18Ni9Ti, 2Cr13, SS304, Nylon, Rubber |

| Design Standard | GB/T 12283, API 607 |

Main Dimensions & Weight

| Nominal Diameter (DN) | L (mm) | D (mm) | D1 (mm) | D2 (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 50 | 203 | 152 | 120 | 92 | 16 |

| 100 | 241 | 190 | 168 | 127 | 23 |

| 150 | 305 | 229 | 195 | 157 | 36 |

| 200 | 457 | 356 | 320 | 216 | 59 |

| 250 | 533 | 406 | 362 | 254 | 72 |

| 300 | 686 | 457 | 412 | 305 | 86 |

Functions and Benefits

Functions and Benefits-

Three-Piece Construction: The three-piece design allows for ease of installation and maintenance. Each part is independently replaceable, enhancing cost-efficiency.

-

Forged Construction: Forged parts provide increased strength and durability, ideal for high-pressure systems.

-

Leak Prevention: The backward sealing structure and high-quality seals ensure that the valve maintains a tight, leak-free seal even in extreme conditions.

-

High-Temperature Resistance: Designed to withstand high temperatures, making it suitable for steam applications or high-temperature fluids.

-

Full Bore Design: Allows for smooth, unrestricted flow with minimal pressure drop.

-

Multiple Actuation Options: Compatible with manual, pneumatic, or electric actuators for flexibility based on operational needs.

The 3-Piece Construction Welding Ball Valve (Forging) is suitable for a wide range of applications, including:

-

Oil & Gas: Ideal for use in upstream and downstream systems, handling crude oil, natural gas, and other petroleum-based fluids.

-

Chemical Processing: Controls the flow of chemicals, acids, or other aggressive substances in the chemical industry.

-

Water Treatment: Provides precise fluid regulation for water treatment plants, ensuring no leakage and smooth operation.

-

Power Generation: Used in power plants for controlling steam, water, and other fluids under high pressure and temperature.

-

Mining: Handles fluid flow in mining operations where robust sealing and durability are required.