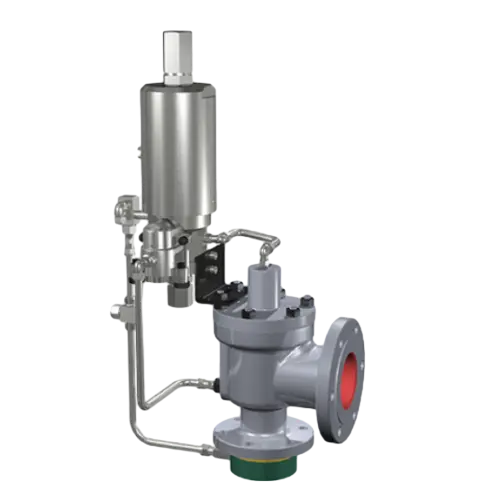

Pilot Operated Relief Safety Valve

Product Overview

Product Overview

At Vcore Valve Company, we offer innovative solutions for pressure control in demanding industrial environments. Our Pilot Operated Relief Safety Valve is a high-performance valve designed to provide precise pressure relief and maintain system safety by preventing overpressure. This valve is particularly effective in systems that require precise control and fast response to pressure changes.

The Pilot Operated Relief Safety Valve operates using a pilot valve to control the opening of the main valve, providing more accurate pressure relief compared to traditional safety valves. When system pressure exceeds a preset threshold, the pilot valve activates the main valve to open and release excess pressure. Once the pressure drops back to safe levels, the valve closes, ensuring continuous protection for your equipment and systems.

Ideal for applications in power generation, oil and gas, chemical processing, and other industries requiring precise pressure control, the pilot operated relief safety valve is engineered for both reliability and performance.

Why Choose Our Pilot Operated Relief Safety Valve?

-

Precise Pressure Control: The pilot operated design allows for highly accurate pressure settings, ensuring that the valve opens and closes at the exact pressure needed to maintain system integrity.

-

Quick Response: The pilot-operated valve responds rapidly to pressure changes, allowing for fast pressure relief to protect your system and equipment from potential damage caused by overpressure conditions.

-

High Capacity for Pressure Relief: The valve is capable of handling large flow rates, making it ideal for high-capacity systems where rapid pressure relief is critical.

-

Durable and Corrosion-Resistant: Made from high-quality materials such as stainless steel, carbon steel, and other corrosion-resistant alloys, our pilot operated relief safety valve is built to withstand harsh environments, providing long-lasting reliability.

-

Versatile Applications: Whether in steam systems, gas pipelines, or chemical plants, the pilot operated relief safety valve provides precise and effective pressure relief, making it suitable for a wide range of industrial applications.

-

Low Maintenance: With its robust design and few moving parts, the valve requires minimal maintenance, providing a cost-effective solution for long-term operation.

Product Specifications

| Feature | Specification |

|---|---|

| Material | Stainless Steel, Carbon Steel, Alloy Steel (Custom materials available) |

| Size Range | 1 inch to 12 inches (Custom sizes available) |

| Pressure Rating | PN16, PN25, or higher (Custom ratings available) |

| Temperature Range | -20°C to 350°C |

| Flow Capacity | High Flow Rate (Customizable to specific needs) |

| Pilot Valve Type | Spring-loaded Pilot (Adjustable) |

| Set Pressure | Adjustable (Customizable to system requirements) |

| Connection Type | Flanged, Threaded, Welded |

| Application | Oil & Gas, Power Generation, Chemical Processing, Water Treatment, HVAC |

| End Connection | Male/Female Thread, Flanged, Welded |

Key Benefits of Choosing Our Pilot Operated Relief Safety Valve

-

Precise Pressure Relief: The pilot-operated mechanism ensures that the valve opens and closes at the correct pressure, providing highly accurate pressure control and protecting your system from overpressure damage.

-

Faster Response Time: The pilot valve mechanism allows for rapid opening of the main valve when the set pressure is exceeded, ensuring that excess pressure is released quickly and effectively.

-

High Flow Capacity: Designed to handle high flow rates, this valve is ideal for systems with large volumes of fluid, such as in power generation or chemical processing, where large-scale pressure relief is required.

-

Durable Construction: Made from high-quality materials, our valve is corrosion-resistant and built to perform reliably in harsh environments, ensuring a long service life even under extreme conditions.

-

Low Maintenance Design: With fewer moving parts compared to traditional safety valves, our pilot-operated relief valve requires less maintenance, reducing operational costs and improving system efficiency.

Ideal Applications

The Pilot Operated Relief Safety Valve is essential for applications that require precise, high-capacity pressure relief. Some ideal industries and systems include:

-

Power Generation: In power plants, this valve protects boilers, steam systems, and pressure vessels by providing accurate pressure relief and preventing overpressure situations that could damage equipment.

-

Oil & Gas: In oil and gas pipelines and processing facilities, the valve provides fast, reliable pressure relief to prevent dangerous pressure buildups that could lead to equipment failure or leaks.

-

Chemical Processing: In chemical plants, maintaining precise pressure control is essential for safety. The pilot operated relief safety valve ensures that excess pressure is safely released from reactors, storage tanks, and pipelines.

-

Water Treatment: The valve ensures proper pressure relief in water treatment systems, preventing damage to filtration units, pumps, and pipelines caused by overpressure.

-

HVAC Systems: In heating, ventilation, and air conditioning systems, the pilot operated relief valve protects compressors, pumps, and other critical components from the dangers of overpressure.

Installation Guidelines

-

Correct Valve Orientation: Ensure the valve is installed according to the flow direction indicated on the valve body. The pilot valve should be positioned to control the operation of the main valve.

-

Set Pressure Adjustment: Adjust the spring tension of the pilot valve to the required pressure for your system. The valve should open when the system pressure exceeds this preset limit.

-

Connection Types: Choose the appropriate connection type (flanged, threaded, or welded) based on your system’s design. Ensure all connections are securely tightened to avoid leaks.

-

System Testing: After installation, test the system to ensure the valve opens at the correct pressure, releases excess pressure, and closes once the pressure returns to normal levels.

Maintenance Tips

-

Regular Inspections: Periodically inspect the valve for signs of wear, corrosion, or blockages. Ensure that the pilot valve and main valve are operating smoothly and without leaks.

-

Spring Tension Adjustment: Check and adjust the spring tension on the pilot valve as needed to ensure that the valve operates at the correct pressure setting.

-

Cleaning: Clean the valve regularly to remove any debris or contaminants that could affect its performance, particularly in systems with suspended particles or chemicals.

-

Seal and Parts Replacement: If the valve begins to leak or operate inconsistently, replace seals or internal components to maintain optimal performance.

Product Overview

Product Overview