Quick Summary

A balancing valve is a critical component used to regulate and stabilise fluid flow in HVAC and industrial piping systems. Without proper balancing, even the most advanced systems suffer from uneven distribution, wasted energy and persistent operational issues. This comprehensive guide explains how balancing valves work, the different types available, and how to select and apply them correctly for long-term performance and efficiency.

Opening Scenario – Why Systems Fail Without Balancing

Imagine a newly commissioned HVAC system in a commercial building. Some rooms are overheated, others remain cold, and the pumps are running harder than expected. Engineers check the equipment—everything is installed correctly. The real problem? The system was never properly balanced.

This is where a flow balancing valve quietly becomes the most important valve in the entire network.

User Pain Points

Uneven Flow Distribution

Without hydronic balancing, water naturally follows the path of least resistance, starving distant circuits while overfeeding nearby ones.

Excessive Energy Consumption

Poorly balanced systems force pumps to operate at higher speeds, increasing electricity costs and accelerating mechanical wear.

Difficult Commissioning and Maintenance

Systems without proper balancing valves are time-consuming to commission and extremely difficult to troubleshoot later.

Solutions & Professional Recommendations

Solution 1: Use Balancing Valves During Initial System Design

Integrating balancing valves at the design stage ensures accurate flow regulation from day one, reducing commissioning time and future adjustments.

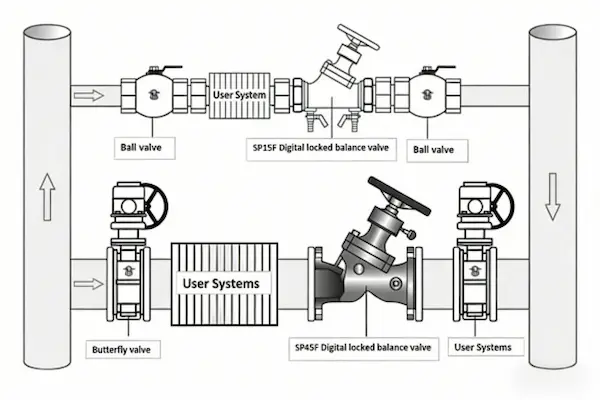

Solution 2: Select the Correct Valve Type for the Application

-

Static balancing valves for manual adjustment

-

Dynamic balancing valves for automatic flow control

-

Differential pressure valves for pressure-independent systems

Solution 3: Combine Valves with Proper Measurement & Commissioning

Using test points and flow indicators allows engineers to verify performance and maintain long-term accuracy.

Case Studies & Practical Examples

Case 1: Commercial HVAC Retrofit

A multi-storey office building suffered from inconsistent heating. By replacing manual valves with dynamic balancing valves, energy consumption dropped by 18% within one heating season.

Case 2: Industrial Cooling Loop

An industrial process line experienced unstable cooling. Installing industrial balancing valves stabilised flow rates and reduced pump cavitation, extending equipment lifespan.

Data, Engineering Logic & Comparison

| Valve Type | Flow Control | Automation | Typical Use |

|---|---|---|---|

| Static Balancing Valve | Manual | No | Small/medium HVAC systems |

| Dynamic Balancing Valve | Automatic | Yes | Modern HVAC networks |

| Differential Pressure Valve | Pressure-independent | Yes | Variable flow systems |

Engineering studies show that correctly applied balancing valves can improve system efficiency by 15–30%, especially in variable-flow HVAC installations.

Trends & Market Insights

-

Growing demand for energy-efficient HVAC systems

-

Increased adoption of pressure-independent balancing valves

-

Smart buildings integrating balancing valves with sensors and BMS

-

Strong growth in industrial flow-control markets due to sustainability regulations

Balancing valves are no longer optional—they are a regulatory and operational necessity.

Style & Usage Recommendations

-

Install balancing valves on each branch circuit, not only at main headers

-

Always document valve settings after commissioning

-

Re-check balancing after major system modifications

-

Choose corrosion-resistant materials for long service life

At On-Off Valve, we recommend selecting valves based on actual flow data, not assumptions.

Conclusion

A well-designed system without proper balancing is like a high-performance engine without tuning. Balancing valves ensure stability, efficiency and predictable performance across HVAC and industrial applications.

At On-Off Valve, we manufacture and supply high-quality balancing valves designed for reliability, accuracy and long-term performance.

👉 Learn more about our engineering capabilities on our About Us page

Optimise your system today — don’t let poor balancing waste energy tomorrow.

FAQ

Q1: What is a balancing valve used for?

A balancing valve regulates flow rate in a piping system to ensure even distribution and stable operation.

Q2: What is the difference between static and dynamic balancing valves?

Static valves require manual adjustment, while dynamic valves automatically maintain correct flow regardless of pressure changes.

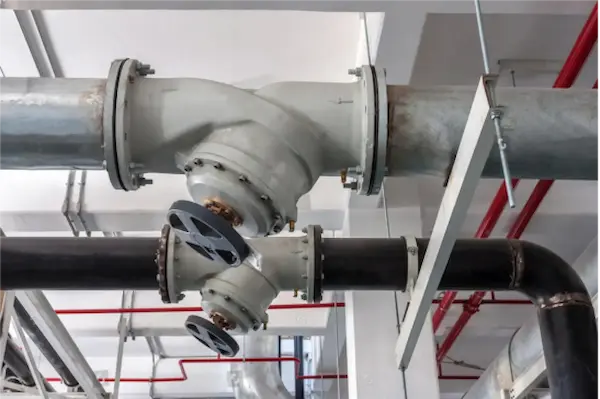

Q3: Where are balancing valves typically installed?

They are commonly installed on branch lines, risers, terminal units and equipment circuits in HVAC systems.

Q4: Do balancing valves improve energy efficiency?

Yes. Proper balancing reduces pump load and energy waste, improving overall system efficiency.

Q5: Are balancing valves required by standards?

Many HVAC design standards and energy regulations strongly recommend or require hydronic balancing.

Q6: Can balancing valves be used in industrial systems?

Absolutely. Industrial balancing valves are widely used in cooling, heating and process fluid systems.