Quick Overview

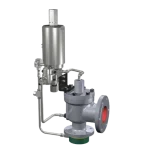

A pressure relief valve is the last line of defence in any pressurised system. When pressure exceeds a safe limit, the valve opens automatically to release excess pressure and protect equipment, pipelines, and—most importantly—people. In this guide, Vcore Valve explains how pressure relief valves work, where they are used, and how to select the right one without overengineering or overspending.

A Real-World Scenario: When Pressure Has Nowhere to Go

Imagine a steam line in continuous operation. Everything runs smoothly—until a downstream valve closes unexpectedly. Pressure spikes. The gauge climbs. Silence follows… and then disaster.

This is exactly where a pressure safety valve proves its value. It doesn’t wait for human intervention. It reacts instantly, releases pressure, and prevents catastrophic failure.

At Vcore Valve, we’ve seen this scenario too many times to count—and we design our valves to stop it before it starts.

Common User Pain Points

1. Confusing Safety Valve vs Relief Valve Definitions

Many engineers still use the terms interchangeably, leading to incorrect valve selection and compliance risks.

2. Incorrect Pressure Rating Selection

Oversized valves cause instability. Undersized valves fail when needed most.

3. Poor Reliability Under Repeated Cycles

Low-quality PRV valves often drift, leak, or stick after repeated pressure events.

Practical Solutions and Expert Recommendations

1. Match Valve Type to Application

Use spring loaded relief valves for simple systems and pilot operated relief valves for high-pressure or large-flow conditions.

2. Always Design for Worst-Case Overpressure

Calculate maximum credible pressure, not normal operating pressure.

3. Choose Certified Industrial Manufacturers

Select valves tested to ASME, API, or ISO standards—this is non-negotiable in industrial environments.

Case Studies from the Field

Case 1: Steam Boiler Protection

A European boiler system replaced a generic safety valve with a Vcore ASME-certified pressure relief valve, reducing nuisance trips by 42% while maintaining full compliance.

Case 2: Chemical Process Line

A pilot-operated relief valve eliminated pressure oscillation issues caused by frequent start-stop cycles.

Data-Driven Comparison: Safety Valve vs Relief Valve

| Feature | Safety Valve | Pressure Relief Valve |

|---|---|---|

| Response Speed | Instant | Gradual |

| Application | Steam & gas | Liquid & mixed media |

| Opening Type | Full lift | Modulating |

| Typical Standards | ASME Section I | ASME Section VIII |

Industry Trends and Market Insights

-

Increasing demand for overpressure protection in hydrogen and renewable energy systems

-

Growing preference for pilot operated relief valves in high-capacity installations

-

Stricter compliance audits driving replacement of uncertified legacy valves

Industrial buyers are shifting from “cheap and available” to “certified and reliable”.

Installation and Usage Best Practices

-

Install vertically whenever possible

-

Never place isolation valves between the system and the relief valve

-

Schedule recalibration based on cycle frequency, not calendar time

A relief valve that isn’t maintained is just decorative metal.

Conclusion and Call to Action

A properly selected industrial pressure relief valve is not a cost—it’s an insurance policy. From steam systems to chemical processing, pressure relief valves silently protect assets every second.

At Vcore Valve, we design and manufacture pressure relief solutions engineered for real industrial abuse—not catalogue promises.

👉 Contact our technical team to select or customise the right relief valve for your application.

FAQ

Q1: What is a pressure relief valve used for?

A pressure relief valve is used to automatically release excess pressure from a system to prevent equipment damage, pipeline failure, or safety hazards caused by overpressure conditions.

Q2: What is the difference between a safety valve and a pressure relief valve?

A safety valve opens fully and rapidly, mainly for gas or steam systems, while a pressure relief valve opens gradually and is commonly used in liquid or mixed-media applications.

Q3: How do I choose the correct pressure relief valve?

Selecting the right pressure relief valve depends on operating pressure, temperature, media type, flow capacity, and compliance with standards such as ASME or API.

Q4: Can a pressure relief valve be adjusted?

Yes, most spring-loaded pressure relief valves can be adjusted within a specified range, but any adjustment should only be carried out by qualified and authorised personnel.

Q5: How often should pressure relief valves be tested?

Testing frequency depends on operating conditions and system criticality, but most industrial pressure relief valves should be inspected or tested annually or after significant pressure events.