Quick Summary

In industrial piping systems, valve performance is only part of the story—installation efficiency and maintenance accessibility often determine long-term reliability and cost. This is where the flanged globe valve proves its value. Compared with welded or threaded connections, flanged globe valves offer easier alignment, faster replacement, and safer maintenance. At Vcore Valve, we see flanged designs consistently outperform alternatives in real plant conditions, especially in steam, chemical, and utility services.

A Typical Site Conversation

“The valve works fine—but replacing it will shut down the whole line.”

This is a common frustration when valves are welded into the pipeline. With a flanged globe valve, the story is very different: unbolt, replace, and restart—no cutting, no hot work, no drama.

User Pain Points in the Field

Difficult Valve Replacement

Welded or threaded valves often require cutting pipes, grinding welds, and requalification—turning simple maintenance into a major shutdown.

Long Downtime During Maintenance

Every extra hour of maintenance means lost production, especially in continuous-process industries.

Alignment and Stress Issues

Poor alignment during installation can introduce stress into the valve body, shortening the service life of industrial globe valves.

Practical Solutions Offered by Flanged Globe Valves

Easy Installation and Removal

A valve flange connection allows precise alignment with pipeline flanges, simplifying installation and reducing the risk of leakage.

Reduced Maintenance Time

Flanged connections make it possible to remove a valve without disturbing surrounding pipework—ideal for routine servicing.

Better Sealing Control

Proper gasket selection and controlled bolt tightening improve globe valve sealing reliability over time.

At Vcore Valve, all flanged globe valves are designed for repeatable installation without compromising performance.

Real Application Case Studies

Case 1: Steam Utility System

A factory replaced welded valves with ASME flanged globe valves in a steam distribution line.

Result:

-

Maintenance time reduced by 50%

-

No hot work permits required

-

Improved safety during shutdowns

Case 2: Chemical Processing Plant

Frequent valve inspection was required due to corrosive media.

Solution: Installed forged steel globe valves with flanged ends

Result: Faster inspections and lower lifecycle cost

Technical Comparison: Flanged vs Other End Connections

| Feature | Flanged Globe Valve | Welded Globe Valve | Threaded Globe Valve |

|---|---|---|---|

| Installation | Simple alignment | Skilled welding | Limited by size |

| Maintenance | Easy removal | Complex, time-consuming | Moderate |

| Leakage risk | Low with a proper gasket | Very low | Higher over time |

| System flexibility | High | Low | Medium |

From a lifecycle perspective, flanged globe valves consistently offer the best balance between reliability and maintainability.

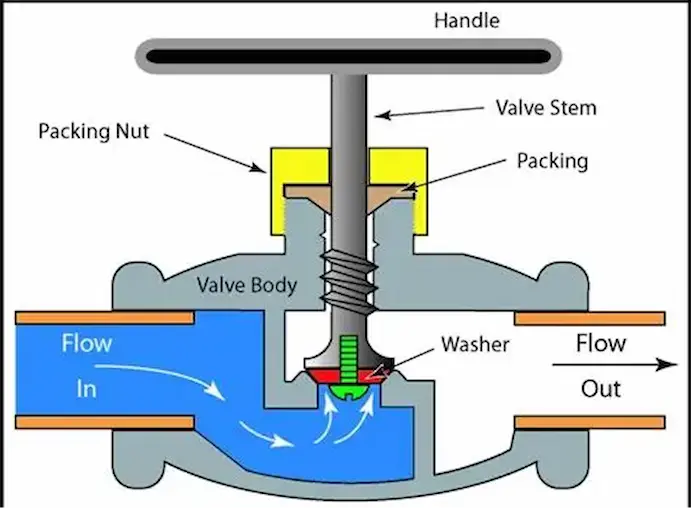

Engineering Logic Behind Flanged Designs

Flanges distribute mechanical loads evenly across the joint, reducing stress on the valve body and bonnet. This is particularly important for:

-

Steam globe valves with thermal expansion

-

High-pressure systems

-

Frequent temperature cycling

Standards such as ASME B16.5 ensure consistent flange dimensions, enabling interchangeability across suppliers.

Market Trends and Industry Insight

-

Increasing preference for flanged valves in modular plant design

-

Strong demand from EPC contractors for maintenance-friendly valves

-

Growth of skid-mounted systems, where flanged globe valves simplify assembly and testing

At Vcore Valve, flanged globe valves remain one of the most requested configurations for export projects.

Best Practice Tips from Vcore Valve

-

Always use gaskets suitable for the temperature and media

-

Tighten flange bolts in a cross pattern

-

Recheck bolt torque after thermal cycling

-

Avoid misalignment during installation—it defeats the purpose of flanges

Related Internal Links (DoFollow):

-

-

Industrial Globe Valves Overview

-

Steam Globe Valve Solutions

-

-

Forged Steel Valve Product Range

Conclusion

Choosing a flanged globe valve is not just a design preference—it is a strategic decision that improves installation efficiency, reduces downtime, and lowers total cost of ownership. For plants where maintenance access and operational flexibility matter, flanged connections are hard to beat.

If you are planning a new project or upgrading an existing system, Vcore Valve is ready to support you with robust, standards-compliant industrial globe valves.

👉 Contact Vcore Valve today for expert advice or customised flanged globe valve solutions.

FAQs

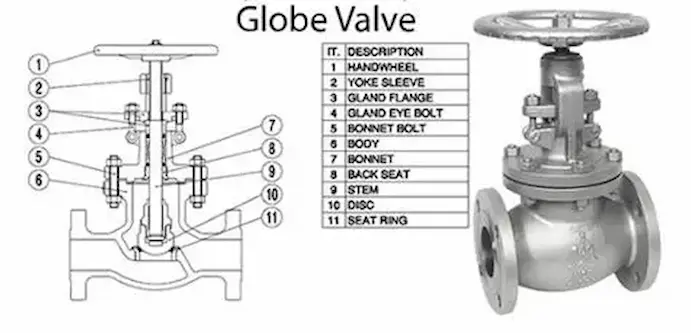

What is a flanged globe valve?

It is a globe valve with flanged ends for bolted connection to pipelines.

Are flanged globe valves better than welded ones?

For maintenance and flexibility, yes. Welded valves may suit permanent installations.

Which standards apply to flanged globe valves?

Common standards include ASME B16.5, ASME B16.34, and EN equivalents.

Do flanged valves leak more?

No, not when installed correctly with proper gaskets and bolt torque.

Are flanged globe valves suitable for high temperature?

Yes, especially in steam and thermal oil systems.

Does Vcore Valve supply flanged globe valves?

Yes. Vcore Valve manufactures flanged globe valves in various materials and pressure classes.

References

-

ASME B16.5 – Pipe Flanges and Flanged Fittings

-

ASME B16.34 – Valves: Pressure–Temperature Ratings

-

API 602 – Compact Steel Gate and Globe Valves

-

Valve Manufacturers Association (VMA) – Valve Installation Guidelines

-

Engineering Toolbox – Valve End Connections Explained

-

ISO 7005 – Metallic Flanges

-

Vcore Valve Technical Library – Globe Valve Installation Guide