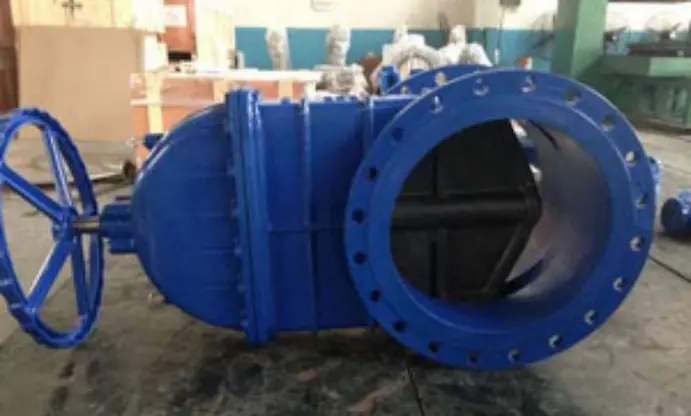

24 Inch Gate Valve

Product Summary

The 24 Inch Gate Valve from Vcore Valve is engineered for large-diameter pipeline systems where reliable shut-off, minimal pressure loss, and long-term durability are essential. Designed primarily for on/off isolation, this valve provides a full bore, straight-through flow path that ensures minimal resistance when fully open. In large infrastructure projects, valve performance, structural strength, and sealing reliability become critical — and this is exactly where a well-designed 24 inch gate valve proves its value.

Gate valves of this size are commonly used in municipal water supply networks, oil and gas pipelines, power plants, petrochemical facilities, and industrial process systems. Compared with smaller valves, a 24 inch gate valve must withstand higher mechanical stress, heavier loads, and more demanding operating conditions. At Vcore Valve, we focus on material selection, precise machining, and robust structural design to ensure consistent performance throughout the valve’s service life.

Key Features & Advantages

🔹 Full Bore, Low Flow Resistance

When fully open, the gate is completely lifted out of the flow path, allowing the medium to pass through without obstruction. This design minimizes pressure drop and turbulence, making the 24 inch gate valve ideal for high-flow applications.

🔹 Heavy-Duty Body Construction

Manufactured from carbon steel, ductile iron, or stainless steel depending on application requirements, the valve body offers excellent mechanical strength and resistance to deformation under high pressure and large pipe loads.

🔹 Reliable Wedge & Seat Design

The valve can be supplied with solid wedge, flexible wedge, or split wedge configurations. Precision-machined seat rings ensure tight sealing, even under varying temperature and pressure conditions.

🔹 Rising Stem or Non-Rising Stem Options

For above-ground installations where visual position indication is important, a rising stem (OS&Y) design is recommended. For space-restricted or buried installations, a non-rising stem version is also available.

🔹 Flanged End Connections

Standard ANSI, ASME, DIN, or EN flanges provide secure and stable connection to large-diameter pipelines, ensuring easy installation and maintenance.

🔹 Long Service Life

Designed for infrequent operation but long-term reliability, the 24 inch gate valve offers excellent wear resistance and sealing performance over extended service cycles.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | 24 Inch Gate Valve |

| Nominal Size | 24″ (DN600) |

| Body Material | Carbon Steel, Ductile Iron, Stainless Steel |

| Wedge Type | Solid Wedge / Flexible Wedge / Split Wedge |

| Seat Material | Metal Seat / Soft Seat (Optional) |

| Stem Type | Rising Stem (OS&Y) / Non-Rising Stem |

| Connection Type | Flanged |

| Pressure Rating | Class 150 / 300 (PN10 / PN16 / PN25 optional) |

| Operating Temperature | -20°C to 425°C (material dependent) |

| Standards | API 600, API 602, ASME B16.34, DIN |

| Operation | Handwheel / Gear Operated |

| Media | Water, Oil, Gas, Steam, Non-Corrosive Fluids |

This configuration makes the valve suitable for both infrastructure and industrial process control systems.

Applications

The Vcore Valve 24 Inch Gate Valve is widely used in demanding large-scale systems, including:

-

Municipal Water Supply & Distribution: Main transmission pipelines, pump stations, and reservoirs.

-

Oil & Gas Pipelines: Crude oil, refined products, and gas transmission lines where full shut-off is required.

-

Power Plants: Cooling water systems, boiler feedwater isolation, and auxiliary pipelines.

-

Petrochemical & Chemical Plants: Process isolation where straight-through flow and tight sealing are critical.

-

Industrial Infrastructure: Steel plants, mining operations, and large-capacity utility pipelines.

In these applications, the gate valve is typically operated in either fully open or fully closed position, making it ideal for isolation rather than throttling.

Why Choose Vcore Valve 24 Inch Gate Valve

At Vcore Valve, we approach large-diameter valve manufacturing with a clear understanding of real project challenges — installation difficulty, operating torque, sealing reliability, and lifecycle cost. Our 24 inch gate valves are designed with structural integrity, machining accuracy, and material reliability as top priorities.

Rather than focusing on unnecessary complexity, we emphasize practical engineering: stable operation, compatibility with international standards, and ease of maintenance in the field. Each valve is inspected to ensure dimensional accuracy, pressure integrity, and smooth operation before delivery.

For contractors, EPC companies, and distributors, this means fewer installation issues, reduced downtime, and dependable long-term performance in critical pipeline systems.