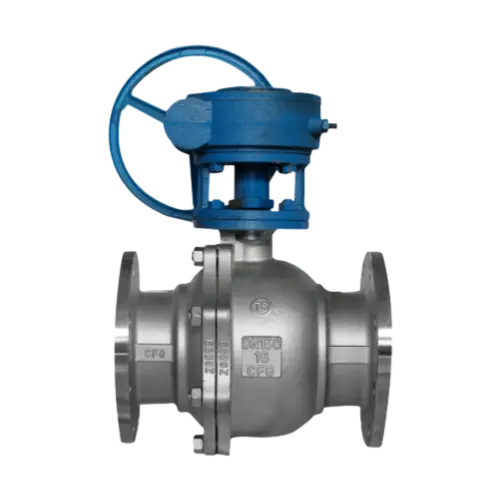

Carbon Steel Ball Valves

At Vcore Valve, we specialize in the design and manufacture of high-quality Carbon Steel Ball Valves. With a reputation for delivering durable, high-performance valves, we focus on meeting the specific needs of industries that require reliable, safe, and cost-effective flow control solutions. Our Carbon Steel Ball Valves are built to endure high-pressure environments and challenging operating conditions, making them a trusted choice for industries across the globe.

What Are Carbon Steel Ball Valves?

Carbon Steel Ball Valves are a type of quarter-turn valve featuring a hollow, perforated ball that controls the flow of liquids or gases through a pipeline. The valve operates by rotating the ball 90 degrees to either open or close the flow path. Known for their strength and durability, carbon steel is the material of choice for these valves, providing excellent resistance to mechanical stresses and a variety of environmental conditions.

Key Features of Vcore Valve Carbon Steel Ball Valves

-

High Durability: Carbon steel, known for its high tensile strength, makes our ball valves resistant to wear and tear. This provides long-lasting reliability in demanding applications.

-

Leak-Tight Performance: Our ball valves are engineered to offer superior sealing performance, reducing the risk of leaks and ensuring secure shutoff under pressure.

-

Easy Operation: The quarter-turn design allows for quick and efficient flow control, offering smooth and precise operation without the need for extensive maintenance.

-

Versatility: Our carbon steel ball valves are suitable for a wide range of applications, from oil and gas pipelines to chemical processing systems, power plants, water treatment facilities, and more.

Materials and Construction

-

Body Material:

-

Carbon Steel (A105, A216, A350)

Carbon steel offers excellent mechanical properties such as high tensile strength, making it perfect for valves subjected to high pressure or demanding environmental conditions. It also ensures resistance to corrosion when properly coated.

-

-

Ball Material:

-

Carbon Steel or Stainless Steel

The ball, which controls fluid flow, is made of carbon steel or stainless steel for strength and longevity. Stainless steel is ideal when enhanced corrosion resistance is required.

-

-

Seat Material:

-

PTFE (Polytetrafluoroethylene)

PTFE is widely used for valve seats due to its excellent chemical resistance and ability to form a tight seal under both high-pressure and low-pressure conditions.

-

-

Stem Material:

-

Stainless Steel (316/304)

Stainless steel stems offer high corrosion resistance and structural integrity, especially in high-temperature or corrosive environments.

-

-

Gasket and Packing:

-

Graphite, PTFE, or Metal Seals

The gaskets and packing materials used in our carbon steel ball valves ensure tight sealing and minimal leakage, even in extreme temperatures and pressures.

-

Properties

-

Pressure Rating:

Our carbon steel ball valves are available in various pressure ratings to suit different applications. Typical pressure ratings include PN16, PN25, PN40, ANSI 150, ANSI 300, and higher, depending on customer specifications. -

Temperature Range:

Vcore Carbon Steel Ball Valves are designed to operate effectively across a broad temperature range, from -20°C to 200°C, with special versions available for higher or lower temperature requirements. -

Flow Capacity:

The flow capacity of our valves is designed to handle high volumes, with options for full-port and reduced-port designs, allowing for maximum flow efficiency or precise flow control, depending on the application. -

End Connections:

Available with a variety of end connections, including flanged, butt-weld, socket weld, and threaded ends, to accommodate different piping systems and installation requirements.

Technical Specifications and Parameters

| Parameter | Details |

|---|---|

| Body Material | Carbon Steel (A105, A216, A350) |

| Ball Material | Carbon Steel or Stainless Steel |

| Seat Material | PTFE (Polytetrafluoroethylene) |

| Stem Material | Stainless Steel 316/304 |

| Pressure Rating | PN16, PN25, PN40, ANSI 150, ANSI 300 |

| Temperature Range | -20°C to 200°C (Special versions available for higher or lower temperatures) |

| End Connections | Flanged, Butt-weld, Socket Weld, Threaded |

| Flow Type | Full Port, Reduced Port |

| Ball Operation | Manual, Electric Actuated, Pneumatic Actuated |

| Gasket/Seal Materials | PTFE, Graphite, Metal Seals |

Common Applications

Vcore Valve’s Carbon Steel Ball Valves are used in numerous industries, where reliable and efficient flow control is crucial:

-

Oil and Gas:

Our ball valves are designed to perform under extreme conditions, ideal for both upstream and downstream oil and gas applications. -

Chemical Processing:

Chemical industries rely on our valves for tight sealing and the ability to handle various corrosive fluids without compromising performance. -

Power Generation:

Carbon Steel Ball Valves are used to control steam, water, and gas flow in power plants, ensuring safety and efficiency in energy production. -

Water Treatment:

These valves are commonly employed in water treatment facilities to control the flow of water and chemicals used in filtration and purification processes. -

HVAC Systems:

Suitable for controlling air and water flow in heating, ventilation, and air conditioning systems.