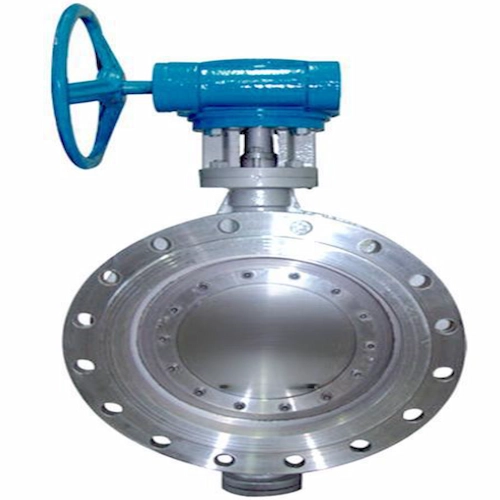

12 – Inch Double Eccentric Butterfly Valve

Production Overview

Production Overview

The 12 – Inch Double Eccentric Butterfly Valve from Vcore Valves is designed for high-performance flow control in large-scale industrial applications. Featuring a double eccentric design, this valve offers improved sealing capabilities and smoother operation, making it ideal for controlling the flow of fluids, including water, oil, gas, and chemicals.

The double eccentric design ensures that the valve’s disc does not come into contact with the seat during operation, reducing wear and tear, and extending the valve’s lifespan. This unique feature minimizes the risk of leakage and ensures a tighter seal, even under high-pressure conditions. The 12-inch diameter makes it suitable for large pipeline systems, while the butterfly disc allows for easy on/off control or modulating flow.

Key Features

-

Double Eccentric Design – Reduces wear and tear, improves sealing, and extends the valve’s lifespan

-

12-Inch Size – Ideal for large pipelines requiring high-flow capacity and efficient flow regulation

-

Reliable Sealing – Ensures minimal leakage under high-pressure conditions with a tighter seal

-

Full-Bore Design – Minimizes pressure drop and ensures smooth flow control

-

Durable Construction – Made from corrosion-resistant materials for longevity in demanding environments

-

Smooth Operation – 90° turn for quick opening/closing with easy manual or automated actuation

-

Low Maintenance – Fewer moving parts and durable materials reduce the need for frequent maintenance

-

Versatile Applications – Suitable for water, oil, gas, chemicals, and slurry systems

-

Global Standards Compliance – Manufactured in accordance with ANSI, ISO, API, and AWWA standards

Technical Specifications

| Item | Description |

|---|---|

| Valve Type | 12 – Inch Double Eccentric Butterfly Valve |

| Body Material | Stainless Steel (304, 316), Ductile Iron, Cast Iron |

| Disc Material | Stainless Steel (304, 316), Aluminum, Bronze |

| Seat Material | EPDM, PTFE, NBR |

| Stem Material | Stainless Steel (304, 316) |

| Coating | Fusion Bonded Epoxy (FBE), Anti-Corrosion Coating |

| Size Range | 12 Inch (DN300) |

| Pressure Rating | PN10 / PN16 / PN25 / 150LB |

| Temperature Rating | -10°C to +150°C (EPDM seat), up to 250°C (PTFE seat) |

| Connection Type | Flanged (ANSI B16.34) |

| Actuation Options | Manual, Pneumatic, Electric Actuator |

| Seat Type | Soft Seat (EPDM, NBR), Metal Seat (304, 316 Stainless Steel) |

| Application | Water, Oil, Gas, Chemicals, Slurries, HVAC |

| Standards Compliance | API 6D, ISO 9001, ANSI B16.34, AWWA C507 |

Main Dimensions & Weight

| DN (mm) | L (mm) | H (mm) | W (mm) | Weight (kg) |

|---|---|---|---|---|

| 300 | 330 | 380 | 250 | 45.0 |

Function

Function

The 12 – Inch Double Eccentric Butterfly Valve operates using a rotating disc inside the valve body. The double eccentric design means that the axis of the valve stem is offset from the centerline of the disc and seat, ensuring that the disc does not touch the seat during operation, which reduces wear, minimizes friction, and provides a tighter seal. This feature enhances the valve’s performance, particularly in applications where leakage control is critical.

When the valve is open, the disc rotates to align with the flow path, allowing the fluid to flow freely. When the valve is closed, the disc rotates to block the flow and forms a tight seal against the seat. The valve’s full-bore design ensures that fluid flows through with minimal resistance and pressure drop when the valve is open.

Constructed from high-quality materials like stainless steel, ductile iron, and cast iron, the Double Eccentric Butterfly Valve is durable and reliable, providing a cost-effective solution for industries requiring efficient fluid control with minimal maintenance.

Application

Application

-

Water Treatment – Flow control and isolation in filtration and treatment plants

-

Oil & Gas – Isolation and regulation of oil, gas, and petrochemical fluids in pipelines and processing systems

-

Chemical Processing – Flow regulation in chemical reactors, pipelines, and manufacturing systems

-

HVAC – Isolation and regulation of water flow in heating, ventilation, and air conditioning systems

-

Slurry Systems – Isolation and regulation of slurry flow in mining, cement, and industrial applications

-

Food & Beverage – Flow control in food production lines for liquid products like oils, juices, and syrups

-

Pharmaceuticals – Flow regulation in pharmaceutical production lines and distribution systems

Production Overview

Production Overview Function

Function Application

Application