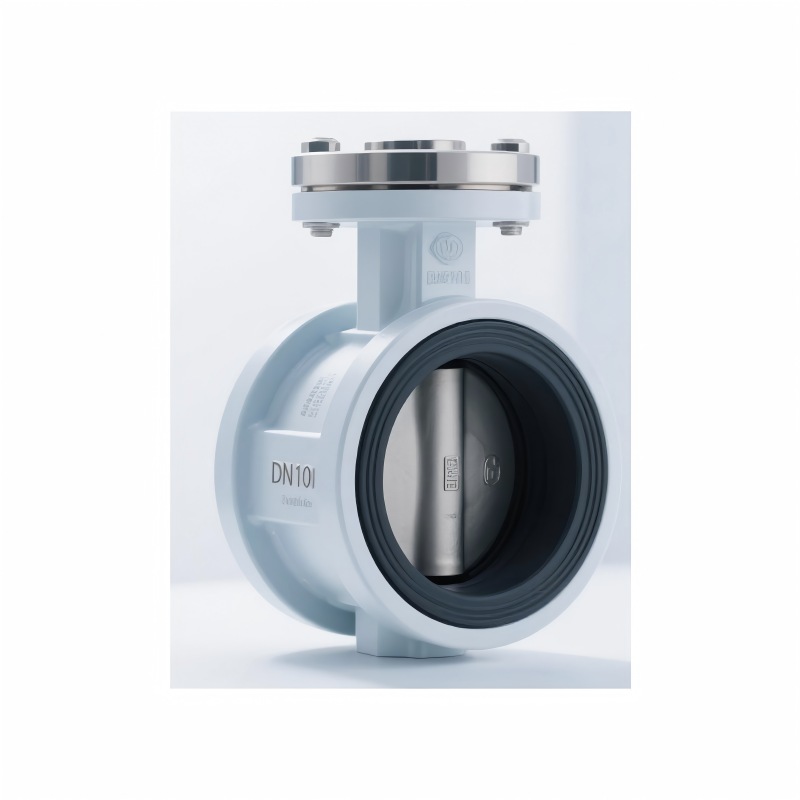

Soft Sealing Butterfly Valve

The Soft Sealing Butterfly Valve is a highly versatile valve designed for controlling the flow of liquids, gases, and slurry in various industrial systems. Equipped with a soft sealing mechanism, this valve provides tight shut-off capabilities, ensuring no leakage during operation. Its innovative design and flexible sealing materials make it ideal for applications in water supply, drainage systems, and pipelines that transport gas, foodstuffs, chemicals, and more.

With a wide range of nominal diameters from 50 mm to 2000 mm, the Soft Sealing Butterfly Valve is designed to offer efficient flow regulation, reduced space requirements, and easy installation. This valve is designed for high-pressure systems, with a robust structure that ensures long-term performance and minimal maintenance.

Key Features:

-

Soft Sealing Mechanism: Provides zero leakage sealing even in demanding applications, ensuring reliable operation.

-

Versatile Application: Suitable for water supply, drainage, chemical processes, food processing, and other fluid control systems.

-

Easy Maintenance and Installation: Simple design and reliable performance make it ideal for both new installations and replacements.

-

Wide Temperature Range: With soft sealing materials, the valve performs well under different temperature conditions, making it adaptable to various industrial environments.

Technical Specifications

| Component | Specification |

|---|---|

| Nominal Diameter (DN) | 50 – 2000 mm |

| Nominal Pressure (PN) | 0.6 – 1.6 MPa |

| Test Pressure | 0.9 – 2.4 MPa |

| Temperature Range | -10°C to +80°C (depending on sealing material) |

| Sealing Material | Neoprene, PTFE, EPDM, and other specialized materials |

| Body Material | Gray Cast Iron, Ductile Cast Iron, Stainless Steel |

| Actuator Type | Pneumatic, Electric, or Manual |

| Sealing Type | Soft Sealing with zero leakage in both open and closed positions |

| Test Standard | Designed and manufactured according to GB/T12283, GB/T9115, JB/T79 |

| Flange Standard | According to GB/T9113-2000, JB/T79-94 |

Dimensional and Weight Specifications

| Nominal Diameter (DN) | L (mm) | D (mm) | D1 (mm) | D2 (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 50 | 210 | 230 | 115 | 75 | 10.6 |

| 80 | 250 | 260 | 145 | 95 | 16 |

| 100 | 300 | 300 | 160 | 105 | 19 |

| 150 | 350 | 350 | 180 | 115 | 28.7 |

| 200 | 400 | 400 | 200 | 130 | 56 |

| 300 | 450 | 450 | 230 | 150 | 76 |

-

Zero Leakage Sealing: The valve’s unique soft-sealing design provides reliable leakage prevention during operation, even in high-pressure and high-temperature conditions.

-

Efficient Flow Regulation: Ideal for regulating the flow of water, gases, slurries, and chemicals with high accuracy and minimal fluid loss.

-

Wide Range of Applications: Used in industries including water treatment, petrochemical, food and beverage, pharmaceutical, and more, making it a versatile solution for many systems.

-

Long-Term Durability: Made with durable materials such as stainless steel and ductile iron, the valve ensures a long service life with minimal maintenance.

-

Simple and Cost-Effective: The straightforward design and ease of installation make this valve cost-effective for a variety of projects.

Applications

The Soft Sealing Butterfly Valve is ideal for a wide variety of industrial applications, including:

-

Water Supply & Drainage: Ensures efficient flow control in water supply and wastewater systems, preventing leaks and maintaining consistent flow.

-

Chemical Processing: Manages the flow of chemicals in manufacturing processes, ensuring accurate control and preventing hazardous leaks.

-

Oil & Gas: Ideal for regulating fluid and gas flow in pipelines, refineries, and other oil and gas operations.

-

Food & Beverage: Ensures hygienic flow regulation in food processing plants, meeting strict industry standards for fluid handling.

-

Pharmaceutical: Controls fluid flow in pharmaceutical applications where precise regulation and zero leakage are essential.