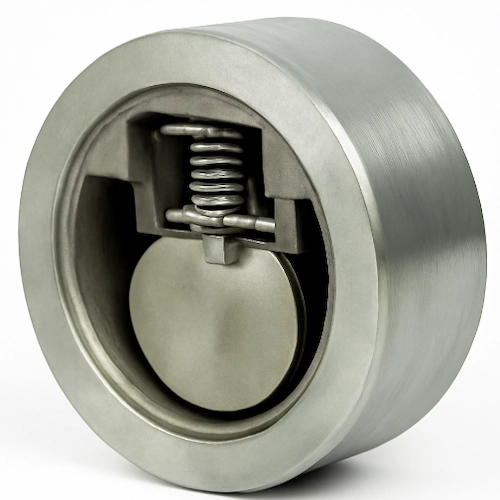

Wafer Lift Type Check Valve

The Wafer Lift Type Check Valve is a compact, high-performance valve designed to prevent reverse flow in pipelines. Featuring a vertical lift disc mechanism, this valve ensures precise sealing and minimal pressure loss. It’s ideal for clean media such as water, steam, oil, air, and various chemical solutions.

Crafted from durable materials like WCB, CF8, and CF8M, and designed for use under varying pressures (1.0–4.0 MPa), the valve offers excellent corrosion resistance, long service life, and fast response in low-pressure environments.

Key Features:

-

Space-saving wafer design, easy to install between flanges.

-

Lift disc structure with vertical movement for quick shutoff and minimal wear.

-

Excellent sealing performance in horizontal or vertical pipe runs.

-

Wide material options (WCB, SS304, SS316, CF8, CF8M, etc.) for diverse media.

-

Abrasion-resistant sealing with proven long-cycle durability.

-

Adaptable to low-pressure environments, especially where space and weight are limited.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Nominal Pressure | 1.0 MPa, 1.6 MPa, 2.5 MPa, 4.0 MPa |

| Test Pressure (Strength) | 1.5 MPa, 2.4 MPa, 2.75 MPa, 6.0 MPa |

| Test Pressure (Seal) | 1.1 MPa, 1.7 MPa, 2.75 MPa, 4.4 MPa |

| Nominal Diameter | DN15 to DN300 |

| Medium | Water, steam, oil, air, weak acids |

| Temperature Range | ≤425°C (WCB), ≤200°C (Stainless Steel) |

| Connection Type | Wafer between flanges |

| Body Material Options | WCB, 2Cr13, 1Cr18Ni9Ti, CF8, CF8M, CF3M |

| Disc Material | Stainless Steel, Alloy Steel |

| Sealing | Metal seated or soft seated (PTFE/Graphite) |

| Nominal Pressure (MPa) | Nominal Diameter (DN) | L (mm) | 1.0 MPa (D) | 1.6 MPa (D) | 2.5 MPa (D) | 4.0 MPa (D) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| 15 | 25 | 48 | 48 | 48 | 48 | 0.3 | |

| 20 | 31.5 | 58 | 58 | 58 | 58 | 0.6 | |

| 25 | 35.5 | 68 | 68 | 68 | 68 | 0.8 | |

| 32 | 40 | 80 | 80 | 80 | 80 | 1.6 | |

| 40 | 50 | 90 | 90 | 90 | 90 | 1.6 | |

| 50 | 60 | 100 | 100 | 100 | 100 | 2.5 | |

| 65 | 65 | 125 | 125 | 125 | 125 | 3.4 | |

| 80 | 71 | 143 | 143 | 143 | 143 | 5.1 | |

| 100 | 80 | 153 | 153 | 153 | 153 | 6.2 | |

| 150 | 100 | 160 | 160 | 160 | 160 | 9.6 | |

| 200 | 150 | 250 | 250 | 250 | 250 | 13.8 | |

| 250 | 200 | 327 | 327 | 340 | 340 | 18.6 | |

| 300 | 250 | 377 | 377 | 385 | 400 | 27 |

Application Fields:

-

Petrochemical Pipelines – Backflow protection for oil, gas & chemical lines.

-

Boiler and Steam Systems – Reliable steam isolation and pressure protection.

-

Water Treatment Plants – Compact solution for flow control in pressurized systems.

-

Power Stations – Ensures one-way flow in thermal and hydro power cooling loops.

-

Industrial HVAC Systems – Prevents reverse flow in hot/cold water loops.