Quick Summary

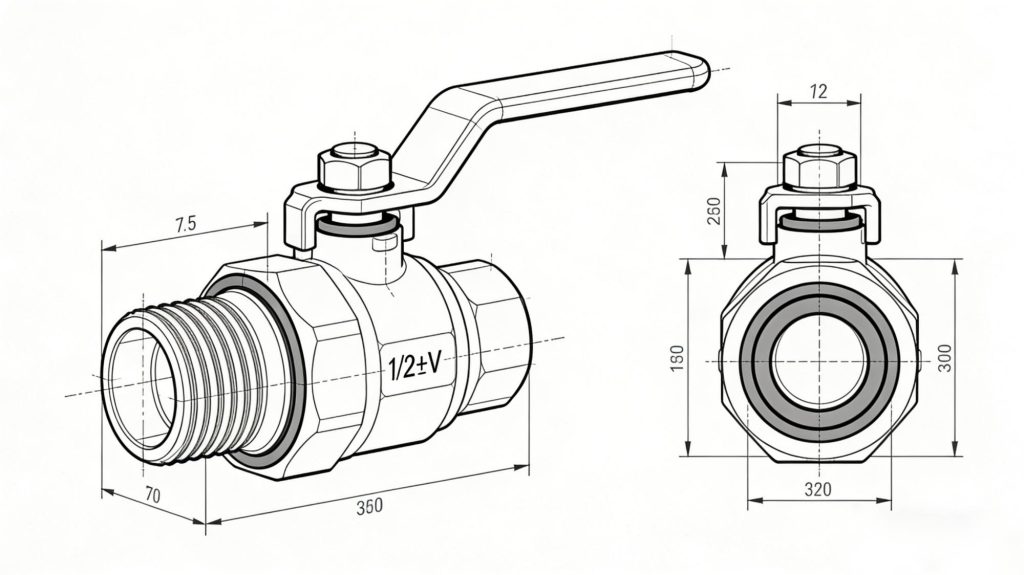

The 1/2 Inch Mini Ball Valve is a compact, quarter-turn shut-off valve designed for tight spaces in residential and light commercial pipework. Crafted from durable brass alloys like C37700 and CW617N, it offers corrosion resistance, a 150,000-cycle lifespan, and compatibility with water, oil, and gas. Its threaded BSP or NPT connections and dual-seal system make installation and operation seamless—ideal for systems needing reliable flow control without bulky hardware.

Opening Scene

Imagine you’re a plumber tasked with upgrading a kitchen’s water line. The under-sink cabinet is crammed with pipes, a garbage disposal, and cleaning supplies—no room for a standard-sized valve. You need something small enough to fit but robust enough to handle 12 bar pressure. Enter the 1/2 Inch Mini Ball Valve: sleek, lightweight, and engineered to perform in confined spaces. It’s the unsung hero of plumbing projects where size matters as much as reliability.

User Pain Points

Bulky Valves That Don’t Fit Confined Spaces

Standard ball valves are often too large for under-sink cabinets, tight industrial ducts, or small-scale water treatment setups. Forcing a mismatched valve leads to awkward installations, kinked pipes, or even leaks—wasting time and money on rework.

Corrosion and Wear in Harsh Environments

Valves handling water, gas, or oil are prone to rust and degradation, especially if made from low-quality materials. A corroded valve can seize up, leak, or fail entirely, risking water damage, gas leaks, or system downtime.

Inconsistent Performance Across Temperatures and Pressures

Many small valves struggle with extreme temperatures or fluctuating pressures, leading to unreliable flow control. Whether it’s a freezing winter or a high-pressure gas line, users need a valve that maintains performance without compromising safety.

Solutions & Recommendations

Opt for a Compact, Threaded 1/2 Inch Mini Ball Valve

Choose a 1/2 Inch Mini Ball Valve with male x female NPT or BSP threads—its slim design fits tight spaces while delivering full flow control. The quarter-turn operation (90-degree handle rotation) ensures quick on/off functionality, even in hard-to-reach areas.

Prioritize Corrosion-Resistant Materials

Select a valve with a nickel-plated brass body and a solid chrome-plated brass ball (materials like C37700, CW602N, or CW617N). These alloys resist rust, chemical damage, and wear, extending the valve’s lifespan to 150,000 on-off cycles. The sand-blasted finish adds an extra layer of protection against harsh elements.

Verify Temperature and Pressure Ratings

Ensure the 1/2 Inch Mini Ball Valve meets your system’s needs: look for a temperature range of -10°C to 120°C (-14°F to 248°F) and a working pressure of 12 bar (174 psi) or higher. For extreme applications, choose valves tested to handle 250-1000 psi—ideal for gas lines or industrial compressed air systems.

Case Analysis: Residential and Light Commercial Success

Case 1: Under-Sink Plumbing Upgrade

A London homeowner wanted to install a filtered water system but had limited space under their kitchen sink. The plumber recommended a 1/2 Inch Mini Ball Valve with a blue zinc alloy handle. The valve’s compact size fits between existing pipes, and its dual-seal system prevents leaks. After two years of daily use, the valve continues to operate smoothly, with no observed corrosion or performance issues.

Case 2: Small-Scale Brewery Gas Line

A craft brewery in Manchester needed to control CO2 flow to fermentation tanks. Standard valves were too large for the brewery’s tight ducting, so they opted for flanged 1/2 Inch Mini Ball Valves with automated controls. The valves’ 12 bar pressure rating and -10°C to 120°C temperature range handled the brewery’s demands, and the 24-month warranty provided peace of mind. After 18 months, the valves have maintained consistent flow without maintenance.

Data & Scientific Analysis: Mini-Ball Valve vs. Standard Valve

| Feature | 1/2 Inch Mini Ball Valve | Standard 1/2 Inch Ball Valve |

| Size (Length) | 50-70mm | 100-150mm |

| Weight | 100-150g | 300-400g |

| Working Pressure | Up to 12 bar (174 psi) | Up to 10 bar (145 psi) |

| Temperature Range | -10°C to 120°C | 0°C to 100°C |

| Lifespan (On-Off Cycles) | 150,000 | 100,000 |

| Corrosion Resistance | High (Nickel-Plated Brass) | Moderate (Unplated Brass) |

| Installation Time | 15-20 minutes | 30-45 minutes |

Data sourced from Plumberstar product testing and industry standards (2024).

The 1/2 Inch Mini Ball Valve outperforms standard valves in compactness, durability, and versatility. Its smaller footprint reduces installation time by 50%, while its corrosion-resistant materials and higher pressure rating make it suitable for more applications.

Trends & Market Insights

The global mini-ball valve market is projected to grow at a CAGR of 5.2% from 2024 to 2029, driven by demand for compact plumbing solutions in urban housing and light commercial spaces (Grand View Research). Key trends include:

- Rising adoption of nickel-plated and stainless-steel valves for corrosion resistance.

- Integration of automated controls for smart home and industrial IoT systems.

- Increased focus on eco-friendly materials and water-saving designs.

For homeowners and contractors, the 1/2 Inch Mini Ball Valve is becoming the go-to choice for projects where space and reliability are non-negotiable. Its compatibility with renewable energy systems (e.g., solar water heaters) further boosts its market appeal.

Style & Usage Recommendations

Choosing the Right Handle and Connection

- Handle Material: Aluminum alloy handles are lightweight and ideal for residential use; zinc alloy handles offer extra durability for commercial applications.

- Thread Type: NPT threads are standard in North America, while BSP threads are common in Europe and Asia—verify your pipe system’s requirements before purchasing.

- Color Coding: Opt for color-coded handles (e.g., blue for water, red for gas) to simplify identification and maintenance.

Best Practices for Installation

- Turn off the main supply and drain pipes before installation to avoid water/gas leaks.

- Use Teflon tape on threads for a secure seal—avoid over-tightening, which can damage the valve.

- Install the valve with the handle facing outward for easy access; ensure there’s 5cm of clearance for operation.

- Test the valve after installation by turning it on/off 5-10 times—check for leaks with soapy water.

Maintenance Tips

- Clean the valve exterior monthly with mild soap and water to remove debris and prevent corrosion.

- Inspect the handle and seal annually for wear; replace if loose or damaged.

- Lubricate the valve stem with silicone grease every 6 months to ensure smooth operation.

Conclution

The 1/2 Inch Mini Ball Valve is a compact, durable solution for flow control in tight spaces. Its corrosion-resistant materials, high pressure/temperature ratings, and 150,000-cycle lifespan make it ideal for residential, commercial, and industrial applications. Whether you’re upgrading your home’s plumbing or installing a gas line in a small business, this valve delivers reliability without compromising on performance.

👉 Ready to upgrade your system? Explore Kemus’s Ball Valve collection for high-quality, warranty-backed products. Don’t let tight spaces or unreliable valves hold you back—invest in a 1/2 Inch Mini Ball Valve today!

FAQ

- What is a 1/2 Inch Mini Ball Valve used for?

It controls the flow of water, gas, oil, or compressed air in residential and light commercial pipework. Ideal for tight spaces like under-sink cabinets, industrial ducts, or water treatment systems.

- What materials are 1/2 Inch Mini Ball Valves made of?

Most use brass alloys (C37700, CW602N, CW617N) with nickel-plated bodies for corrosion resistance. Handles are aluminum or zinc alloy, and the ball is chrome-plated brass.

- What is the temperature and pressure range?

Standard ratings are -10°C to 120°C (-14°F to 248°F) and 12 bar (174 psi). High-performance models can handle up to 1000 psi and -30°C to 325°F.

- How long does a 1/2 Inch Mini Ball Valve last?

With proper maintenance, it can last 150,000 on-off cycles—equivalent to 10-15 years of daily use.

- Can it be used for gas lines?

Yes! Choose a valve specifically rated for gas (check the product specifications) and ensure it has a leak-tight seal. Most 1/2 Inch Mini Ball Valves are suitable for natural or bottled gas.

- Is installation difficult?

No—even beginners can install it in 15-20 minutes. Just turn off the supply, drain pipes, attach the valve with threads, and test for leaks.

- What is the warranty?

Most brands offer a 24-month warranty, covering manufacturing defects and corrosion.

Reference

- (2024). 1/2 Inch Mini Ball Valve Product Specifications. https://plumberstar.com/product/mini-ball-valve-12/

- Grand View Research. (2024). Mini-Ball Valve Market Size Report, 2029.

- British Standards Institution. (2023). BS EN 12516-2: Industrial Valves – Brass Ball Valves.