- Home >

- Products

Vcore Valve Products – High-Quality Valve

At VcoreValve, we specialize in providing high-quality valve solutions for various industrial applications. Our extensive product line includes Gate Valves, Ball Valves, Globe Valves, Butterfly Valves, Check Valves, and Control Valves, all engineered for optimal performance in tough operational environments. Each valve is designed to meet industry-specific needs, from flow regulation to pressure control, ensuring safety and efficiency across diverse sectors such as oil & gas, power generation, and chemical processing.

Our Gate Valves offer reliable sealing and are ideal for applications that require full flow and precise shutoff. Ball Valves are perfect for quick and efficient flow control, while Globe Valves excel in fine adjustments of flow rates and pressure. For larger flow volumes in low-pressure systems, Butterfly Valves provide a lightweight, space-saving solution. Additionally, our Check Valves prevent backflow, protecting systems from damage, and our Control Valves allow for precise regulation of fluid flow, pressure, and temperature in critical processes.

Each product is made from high-quality materials and undergoes rigorous testing to ensure durability and long-lasting performance. Whether you’re in need of a standard valve or a customized solution, Vcore Valve offers expert support and a wide range of options to suit your needs, ensuring your systems run smoothly and efficiently.

GLOBE VALVE

GATE VALVE

BUTTERFLY VALVE

CHECK VALVE

CONTROL VALVE

Custom Fabrication for Valve Components and Systems

Vcore Valves specializes in the fabrication of precision components for the valve industry. We offer customized solutions for valve bodies, covers, flanges, and other critical parts, ensuring the highest standards of quality, performance, and durability. Our manufacturing processes include

Material Selection and Cutting: We use advanced cutting techniques, such as laser cutting and CNC machining, to shape materials like stainless steel, carbon steel, and alloys, tailored for valve body components and structural parts.

Welding and Assembly: Various welding techniques, such as TIG and MIG welding, are employed to create durable, leak-proof joints for valve assembly. We focus on precise, high-strength welding for high-pressure and high-temperature applications.

Bending and Forming: Using CNC bending machines, we shape valve parts like bodies and flanges, ensuring that each part fits the required specifications.

Additional Fabrication Processes: Our expertise extends to drilling, punching, threading, and finishing to meet the needs of valve systems, guaranteeing smooth operation and performance under extreme conditions.

Vcore Valves – Introduction to Our Valve Solutions

At Vcore Valve, we are committed to providing robust and reliable valve solutions for diverse industrial applications. Our range includes high-performance Gate Valves, Ball Valves, Globe Valves, Butterfly Valves, Check Valves, and Control Valves, each meticulously crafted to meet the highest standards of quality and precision. With a focus on reliability, our valves are engineered to deliver exceptional performance even in the most demanding environments, offering tailored solutions to industries such as oil & gas, chemical processing, and power generation.

We recognize the need for versatility, which is why Vcore Valve offers valves suitable for a variety of operational requirements, from sealing and flow regulation to pressure control. Whether it’s ensuring a tight seal for shutoff, enabling rapid flow control, or providing fine flow adjustments, our products are designed to optimize system performance and improve operational efficiency.

Every valve is crafted using premium materials and undergoes thorough testing to guarantee durability, corrosion resistance, and long-term reliability. Additionally, with options for customized solutions and a commitment to exceptional customer support, Vcore Valve ensures that your systems remain optimized for continuous, smooth, and safe operations

characteristics and Advantages of Vcore Valves

| Characteristic | Advantage | Description |

|---|---|---|

| Premium Materials | Long-lasting durability and corrosion resistance |

Vcore valves are manufactured from high-grade stainless steel, carbon steel, and brass, ensuring strength, wear resistance, and extended service life in harsh industrial environments. |

| Precision Manufacturing | Reliable sealing and smooth operation | With advanced CNC machining and strict quality control, every valve is produced with accurate dimensions, tight shut-off, and consistent performance across different pressure and temperature ranges. |

| Wide Product Range | Versatile solutions for different industries | Offering multiple types including Gate Valves, Ball Valves, Globe Valves, Butterfly Valves, Check Valves, and Control Valves, as well as connections such as flanged, threaded, and welded, VOCRE valves are widely used in oil & gas, chemical processing, water treatment, HVAC, and power generation. |

| Fast Delivery & Customization | Flexible solutions tailored to projects | We maintain a large stock of standard valve models for quick shipment and provide custom-engineered solutions to meet unique project specifications, ensuring efficiency and reduced downtime. |

| Professional Support | End-to-end service and technical expertise | Our experienced technical consultants assist clients with valve selection, application advice, and troubleshooting, backed by responsive after-sales service for reliable long-term operation. |

♻️ Certified for Valves

All Vcore Valves are certified by internationally recognized authorities:

✅ Certified OK-Compost Home & Industrial (TÜV Austria) – suitable for home and industrial composting

✅ Compliant with EN13432 & ASTM D6400 (US & EU compostability standards)

✅ Manufactured in BRC- and NSF-certified facilities ensuring hygiene and food-grade safety

✅ FDA and SGS approved for food contact applications

✅ Produced in ISO-certified plants with emphasis on water and carbon reduction

Each valve is packed in sugarcane bagasse boxes made from renewable residue—reducing landfill waste and eliminating plastic pollution in food service operations. foodservice operations.

Application Scenarios - Vcore Valve

| Field | Applicable Valve Type | Key Requirements & Features |

|---|---|---|

| Petroleum & Natural Gas | Fully Welded Ball Valve | Designed to withstand geological subsidence and extreme conditions; available in Class 900 high-pressure ratings for safe and reliable long-distance pipeline operations. |

| Chemical & Pharmaceutical | Flanged / Threaded Ball Valve | Manufactured with corrosion-resistant stainless steel (SS316L), ensuring long-term durability in highly corrosive chemical media and pharmaceutical processing. |

| Food & Medical Industry | Sanitary Ball Valve | Hygienic zero dead-angle design for complete cleaning and sterilization, meeting strict FDA and GMP standards for food and medical fluid systems. |

| Energy & Power | V-type Control Ball Valve | Provides precise flow regulation of slurry, steam, or thermal fluids; ideal for applications requiring accurate throttling and durability in power plants. |

| Semiconductor Industry | High Purity Gas Ball Valve | Specially engineered with an ultra-thin valve body to minimize gas residue and contamination, ensuring high-purity gas delivery for semiconductor production. |

Packing Specifications – Vcore Valve

Protection Requirements

1.Each ball valve is carefully coated with high-quality anti-rust grease to ensure long-term corrosion protection. The flange surfaces are secured with solid wooden covers to prevent impact and mechanical damage during storage or transportation.

2.For threaded valves, durable plastic sheaths are applied to the valve ends, effectively protecting the threads from deformation, dust, and external damage.

Transportation Packaging

1.Carbon steel valves are packed in reinforced wooden cases, lined with moisture-proof paper to maintain dryness. The packaging ensures safe storage under conditions where humidity does not exceed 60%, preventing rust and structural damage.

2.Small-size valves such as butterfly valves, check valves, and control valves are securely packed in high-strength cartons with internal foam padding, providing excellent shock resistance and stability during transportation.

Vcore Product Design

Precision Engineering · Innovative Thinking · Practical Solutions

Function-Oriented Design, Smart Structure & Compact Form, Advanced CAD/CAE Integration, Customized Engineering for Industry Needs, Innovation Meets Sustainability.

At Vcore, design is not just about appearance — it’s about performance, safety, and adding real value to every application.

FAQ of Vcore Valves

1.How to choose between a Floating Ball Valve and a Trunnion Mounted (Fixed) Ball Valve?

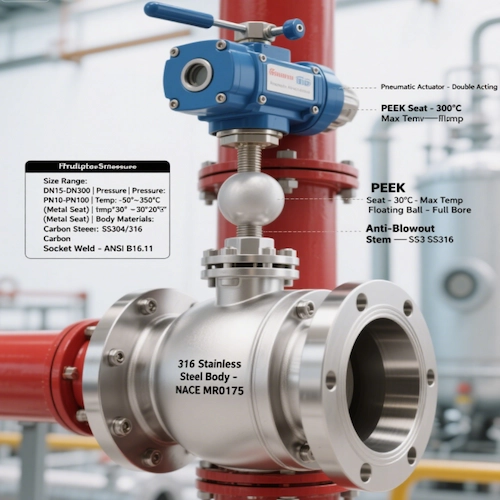

Floating Ball Valve: Recommended for pipelines DN ≤150mmand low-pressure applications. The ball relies on medium pressure to achieve sealing.

Trunnion Mounted Ball Valve: Suitable for DN >150mmand high-pressure pipelines (such as oil & gas trunk lines). With an independent bearing structure, it offers excellent pressure resistance and long-term sealing reliability.

2.What are the application scenarios for Thin Ball Valves?

Thin ball valves are ideal for space-limited environments such as compressors, ship engine rooms, and compact systems. They reduce installation thickness by about 40%, with nearly zero flow resistance, making them highly efficient.

3.Can Ball Valves replace Globe Valves for flow regulation?

Standard ball valves are designed for on/off service (full open/full close) and are not suitable for accurate flow regulation. Only V-type Ball Valves can be used for flow adjustment, as their opening is linearly related to flow. For precise throttling, a globe valve or control valve is recommended.

4.Can Ball Valves be used for throttling or flow regulation?

Ball valves can handle limited throttling, but they are not designed for precise regulation. For applications requiring accurate control of fluid flow, control valves or globe valves are the best choice.

5.Are Ball Valves suitable for high-pressure applications?

Yes. Trunnion mounted ball valves are specifically engineered for high-pressure environments. They ensure stable sealing, safety, and performance even under extreme operating conditions in industries such as oil & gas and power generation.

6.Do Ball Valves require regular maintenance?

Ball valves are known for their simple structure and durability, requiring minimal maintenance. However, periodic inspection is recommended to check seals and ensure long-term performance, especially in high-cycle or corrosive service environments.

7.Can Ball Valves be automated?

Yes. Vcore ball valves can be equipped with electric or pneumatic actuators, enabling remote or automatic operation. Automated ball valves are widely used in chemical plants, water treatment facilities, and industrial pipelines where frequent operation or difficult access is a concern.

F1. How to choose between floating ball valve and fixed ball valve?

Floating type: DN≤150mm low-pressure pipeline, relying on medium pressure sealing;

Fixed type: DN>150mm high-pressure pipeline (such as oil and gas trunk line), independent bearing structure pressure resistance.

2. What are the applicable scenarios for thin ball valves?

Applicable to space-constrained equipment (compressors, ship engine rooms), the thickness is reduced by 40%, and the flow resistance is close to zero.

3. Can ball valves replace stop valves for flow regulation?

Only V-type ball valves can adjust the flow (the opening is linearly related to the flow), and the standard ball valve full open/full closed design is not suitable for regulation

4. Can ball valves be used for throttling or flow regulation?

Ball valves are primarily designed for on/off control. While they can be used for limited throttling, they are not ideal for precise flow regulation. For accurate throttling, a globe or control valve is recommended.

5. Are ball valves suitable for high-pressure applications?

Yes, especially trunnion mounted ball valves. They are designed for high-pressure environments and provide stable sealing performance under extreme conditions.

6. Do ball valves require regular maintenance?

Ball valves require minimal maintenance due to their simple structure and durable design. However, periodic inspections are recommended to ensure optimal performance, especially in demanding environments.

7. Can ball valves be automated?

Yes. Ball valves can be equipped with electric or pneumatic actuators for remote or automatic control. This is especially useful in industrial processes or locations that are hard to access.