Quick Summary

Choosing the correct valve end connection type is crucial for system safety, efficiency and longevity. Vcore Valve guides you through the pros and cons of NPT, Flanged and Socket Weld connections — helping you make informed decisions tailored to your application’s pressure, temperature, maintenance and budget needs.

Introduction: Why Valve End Connections Matter

Picture this: you’ve specified valves for your new pipeline, but installation day comes — and the valves don’t match the pipe ends. Or worse: you rush to install threaded valves, only to find frequent leaks under pressure.

At Vcore Valve, we know mistakes like this can cause costly downtime or even safety hazards. That’s why selecting the correct end connection type matters just as much as the valve itself.

Common User Pain Points

Leakage or failure under high pressure/temperature

Threaded (NPT) connections may work for low-pressure water lines — but under high temperature, pressure, or vibration, they can gradually loosen, causing leaks or failure.

Difficult maintenance or replacement in complex systems

If the valve is welded or permanently fixed (e.g. socket weld), replacing or servicing it often means cutting and rewelding — time-consuming and costly.

Poor match between connection type and pipeline conditions

Choosing a cheap threaded valve for a high-pressure / high-temperature pipeline may save upfront cost — but can cause safety issues or frequent maintenance later.

Solutions & Recommendations from Vcore Valve

🛠️Match connection type to operating conditions

-

Use NPT (threaded) connections for low-pressure, low-temperature systems (e.g. small water or air pipelines).

-

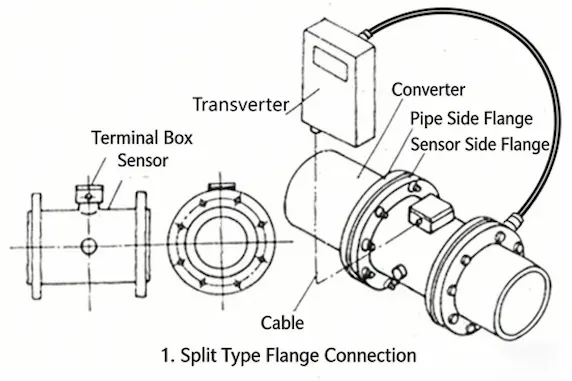

Opt for Flanged connections for medium to high pressure/temperature, or where maintenance access is required.

-

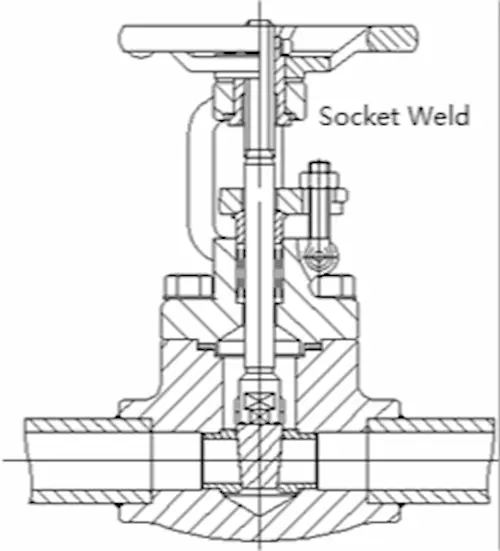

Use Socket Weld (or other welded ends) for small-bore, high-pressure/high-temperature systems where permanent and leak-tight joints are essential.

🔧Consider maintenance frequency and ease of access

If your system requires regular inspection, cleaning or valve replacement, Flanged connections are ideal — bolts can be undone and valve removed without disturbing the rest of the pipeline.

💰 Balance upfront cost vs long-term reliability

For budget-conscious, non-critical installations, NPT may suffice. But for demanding industrial systems, Flanged or Socket Weld offer better long-term performance and safety — avoiding costly leaks or repair downtime.

Comparative Overview: NPT vs Flanged vs Socket Weld

| Connection Type | Best For / Strengths | Limitations / Cautions |

|---|---|---|

| NPT (Threaded) | Low-pressure water/air, small pipelines, easy installation with basic tools | Moderate leak integrity, not ideal under high pressure, vibration, or temperature extremes |

| Flanged | Medium–large pipelines, systems needing maintenance / easy removal, higher pressure & temp | Heavier, more expensive, and needs more installation space |

| Socket Weld | Small bore (≤ 2″), high-pressure/high-temperature, permanent leak-tight connection | Requires skilled welding, difficult to remove or rework, and higher labour cost |

Installation & Maintenance:

-

NPT: quick, tool-light, but can loosen over time under vibration/thermal cycling.

-

Flanged: requires bolt alignment and a gasket, but allows easy dismantling for maintenance.

-

Socket Weld: permanent and leak-proof, but any maintenance requires cutting and rewelding.

Cost Consideration:

-

NPT: lowest upfront cost, minimal installation tools.

-

Flanged: higher material and installation cost — but better long-term value in maintainable systems.

-

Socket Weld: moderate valve cost but higher labour/installation costs; expensive to remove if needed.

Application Scenarios & Practical Advice

-

Small-scale plumbing, water supply, or air lines: choose NPT threaded valves — cost-effective, easy to install, sufficient for low-risk systems.

-

Industrial pipelines with regular maintenance (e.g,. water treatment, process control, chemical): go for Flanged valves — easier to service, adaptable, reliable under pressure.

-

Critical high-pressure / high-temperature lines (e.g,. steam, chemical, gas): prefer Socket Weld valves (or butt-weld variants) — robust, permanent, leak-resistant.

At Vcore Valve, we supply valves in all three connection types — ensuring you get the right fit for your system needs. Explore our About Us page to discover our manufacturing capabilities and quality standards.

FAQ

Q1. What does NPT stand for?

A: NPT = National Pipe Thread Tapered. It refers to valves with threaded, tapered ends designed to form a fluid-tight seal when screwed onto compatible pipe threads.

Q2. When should I avoid using threaded (NPT) valve connections?

A: Threaded valves are not recommended for high-pressure, high-temperature or vibrating systems, as threads may loosen over time, leading to leaks.

Q3. Are flanged valves suitable for all pipe sizes?

A: Yes — flanged end valves can be used across a broad size range and are particularly ideal when maintenance access or disassembly may be needed.

Q4. What are the main drawbacks of socket-weld end valves?

A: Socket-weld connections require skilled welding, are time-consuming to install, and difficult to dismantle — replacement often means cutting and re-welding the pipeline.

Q5. How to choose the right valve connection type for my project?

A: Consider: (1) pipe size, (2) system pressure/temperature, (3) leak integrity and safety, (4) maintenance frequency, (5) budget vs long-term value. Match connection type accordingly.

Q6. Can Vcore Valve supply all connection types (threaded, flanged, welded)?

A: Yes — we manufacture and supply valves with NPT (threaded), Flanged, and Socket/welded ends, to meet diverse project requirements.

Q7. What materials should I consider when selecting valve end connections?

A: Depending on your media and operating conditions, stainless steel, alloy steel, or other corrosion-resistant materials are recommended, especially for high-temperature, corrosive or chemical applications.

References

-

Rick’s Valve — How to Choose Valve End Connection Type: NPT vs Flanged vs Socket Weld

-

ValveMan.com — Choosing the Perfect Valve End Connection Type

-

ValveOnly Europe — Understanding Valve End Connections: Flanged, Threaded, Socket Weld and Butt Weld

-

Generic Valve-Engineering Reference — on pipe size, pressure class and suitability of end connection types