Quick Summary

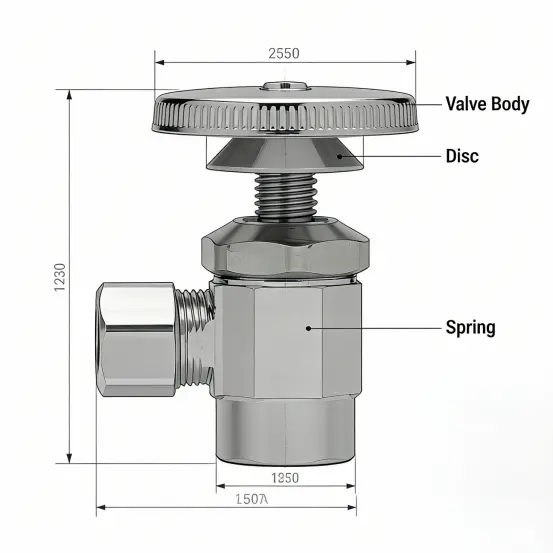

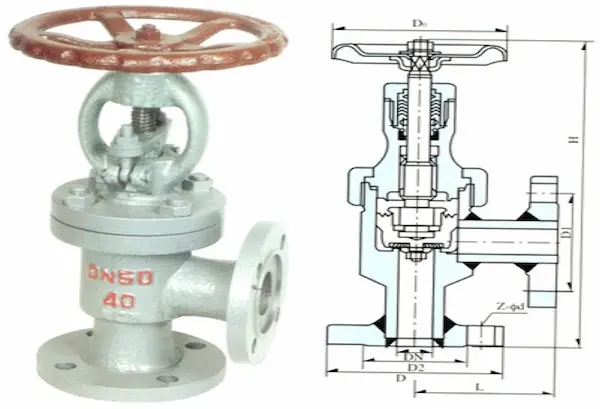

An angle stop valve is a compact, 90-degree shut-off valve often used under sinks, toilets, or for individual appliances. Whether you need a quick repair, periodic maintenance or safe emergency shut-off, the right angle valve ensures reliability, leak-free sealing and long service life. In this guide, Vcore Valve explains how to pick, install, and maintain angle stop valves — helping you avoid common pitfalls.

🏠 Scenario — When You Need an Angle Stop Valve

You’re renovating a bathroom. You remove a basin, only to find rusted supply lines. You want to replace the faucet — but you don’t want to shut off water to the entire house. That’s when you thank your past self for installing a reliable angle stop valve. With a quick quarter-turn, the water per fixture shuts off, and plumbing continues smoothly elsewhere.

Or picture a tenant calling in the middle of the night for a leaking toilet. A robust angle valve under the cistern saves you from a midnight whole-house shutdown — and angry neighbours.

⚠️ Common Pain Points

Confusion over valve types and materials

With options like compression, sweat (soldered), PEX, push-fit, and various metals/plastics, it’s easy to pick the wrong valve type — leading to leaks or premature failure.

Poor sealing or frequent leaks under pressure or corrosion

Cheap plastic or sub-standard valves often crack, deform, or corrode — particularly in hard-water or chemically soft water environments — resulting in drips, losses, or even bursts over time.

Inconvenient maintenance and difficult installation

Some valves require soldering, specialised tools or precise pipe alignment, making changes or repairs costly and time-consuming — annoying for homeowners, costly for maintenance teams.

🛠️ Solutions & Recommendations

Solution A — Choose valve type based on application

-

For standard residential sinks, toilets, or small fixtures: compression angle stop valves or PEX-compatible valves — easy to install, no soldering needed.

-

For reliable long-term performance in more demanding environments: brass or stainless steel valves with corrosion-resistant design.

-

Avoid cheap plastic valves except perhaps in low-risk, temporary installations.

Solution B — Ensure proper installation and regular maintenance

-

Use the correct pipe type (copper, PEX, CPVC) as specified; match valve to pipe material.

-

After installation, always test by shutting on/off, and check for drips. Inspect periodically — especially in mineral-rich water areas.

-

For soldered valves (sweat type), ensure professional soldering to avoid cold joints or leaks.

Solution C — Hold quality & longevity over upfront cost

-

Invest in higher-quality brass or stainless valves. Though costlier initially than plastic or economy valves, their leak-proof sealing and durability save maintenance and replacement fees down the line.

-

Use valves from reputable suppliers (such as Vcore Valve) who supply to both residential and industrial applications.

📚 Types, Materials & Where Each Fits

| Valve Type / Material | Best Use / Strengths | Weaknesses / Cautions |

|---|---|---|

| Compression Angle Valve (Brass / Chrome-plated) | Easy retrofit under sinks or toilets; no soldering needed | Compression rings may wear over time; periodic retightening may be needed |

| PEX-compatible Angle Valve (Brass / Plastic) | Fast installation on PEX / plastic tubing; flexible layout | Plastic variants wear faster; risk of deformation under heat or pressure |

| Sweat (Soldered) Angle Valve (Brass/Copper) | Leak-proof when correctly soldered; good for long-term installations | Requires solder work; not ideal for DIY unless skilled |

| Brass / Stainless Steel / Metal Push-Fit Valve | Quick installation, corrosion-resistant, suitable for potable water | Ensure correct fitting and compatibility; may be more expensive |

🔧 Installation & Usage Tips

-

Always turn off the main water supply before removing or replacing an angle valve, and drain the line fully.

-

For compression valves: ensure the ferrule and nut are properly seated; do not overtighten.

-

For soldered valves: ensure clean copper, correct solder application, and proper cooling to avoid cold joints or weak seals.

-

After installation, turn the water back on slowly, check thoroughly for leaks at the inlet/outlet and around the body.

-

Exercise the valve periodically — open and close fully — to avoid seizing, especially in infrequently used fixtures.

🧰 Real-World Examples

Example 1: Retrofit in an older flat

An owner replaced old, leaking plastic stop valves under the bathroom basin with brass compression angle stop valves. Result: no more leaks for over 5 years, easier faucet replacements, better water pressure control.

Example 2: PEX-based plumbing in a modern apartment

In a newly built apartment using PEX piping, the contractor installed PEX-compatible angle valves under sinks and toilets — quick installation, zero soldering, fast maintenance during fixture upgrades.

🔎 Why Get Your Valves from Vcore Valve

At Vcore Valve, we supply a comprehensive range of angle stop valves, compression valves, PEX valves, brass and stainless stop valves, designed for both residential and commercial applications. With strict quality control and durable materials, we ensure leak-resistant sealing, corrosion resistance and long service life. Feel free to view our full product range on our About Us page.

Conclusion

Choosing the right angle stop valve isn’t optional — it’s essential for safe, efficient and long-lasting plumbing. Whether you’re a homeowner, plumber, or contractor, investing in quality valves and proper installation pays off.

👉 Contact Vcore Valve today for professional advice, quality valves and customised solutions for your project — and ensure every fixture in your building has the right valve to do the job.

❓FAQ

Q1: What is an angle stop valve used for?

A: It’s a 90-degree shut-off valve located under fixtures like sinks or toilets, enabling you to isolate water supply to that fixture without shutting off the entire house water system.

Q2: What types of angle stop valves are there?

A: Common types include compression, sweat (soldered), PEX-compatible, and push-fit valves, each suited for different pipe materials and installation scenarios.

Q3: Which material is best for long-term reliability?

A: Brass or stainless-steel valves are ideal due to corrosion resistance, durability and stable sealing — especially in hard water or frequent-use environments.

Q4: Is soldering required for all angle valves?

A: No. Compression and PEX-compatible valves do not require soldering; push-fit valves are even easier. Only “sweat” angle valves need soldering.

Q5: How do I know when to replace an angle stop valve?

A: Watch for leaks, corrosion, stiffness when turning, or deformation of components. If sealing fails or the valve feels unstable — replace it promptly.

📄 References

-

What Is an Angle Stop Valve? – Fox Plumbing Heating & AC guide.

-

Angle valves tutorial & types – Plumberstar.

-

Valve connection and maintenance guidance – Professional plumbing resources.