Quick Overview

A needle valve is one of the most precise flow control valves used in industrial systems. From instrumentation lines to high-pressure fluid control, needle valves allow operators to regulate flow accurately rather than simply turning it on or off. At Vcore Valve, we see needle valves specified where stability, repeatability, and fine adjustment matter most. This guide explains how needle valves work, where they perform best, and how to select the right one without costly mistakes.

Opening Scenario: A Familiar Engineering Conversation

“Why can’t we just use a ball valve here?”

“We need to control flow, not guess it.”

This conversation happens more often than you might think. When precision matters, a standard on/off valve quickly becomes a liability. That’s exactly where needle valves earn their reputation.

User Pain Points

Inconsistent Flow Control

Many systems fail because operators try to throttle flow using valves that were never designed for precision.

Leakage Under High Pressure

Incorrect valve geometry or poor machining leads to micro-leaks, especially in high-pressure instrumentation lines.

Wrong Material Selection

Choosing the wrong alloy can result in corrosion, galling, or premature wear.

Solutions & Expert Recommendations

Use Needle Valves for Regulation, Not Isolation

A needle valve is designed for gradual, controlled flow adjustment—not rapid shut-off.

Match Valve Design to Pressure and Media

High-pressure or aggressive fluids demand properly engineered needle valves.

Work with Experienced Manufacturers

At Vcore Valve, each industrial needle valve is CNC-machined and pressure-tested to ensure repeatable performance.

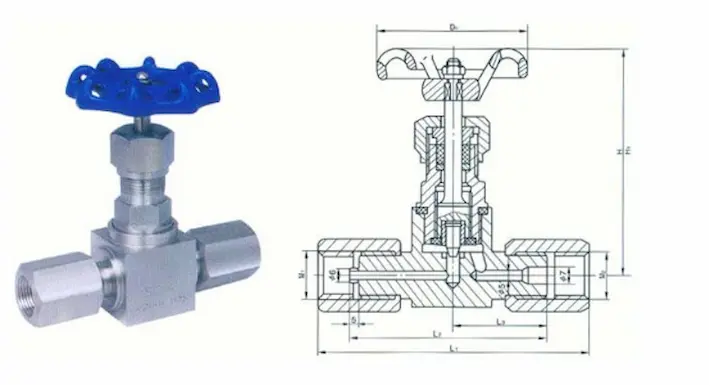

What Is a Needle Valve and How Does It Work?

A needle valve uses a long, tapered stem (the “needle”) that moves gradually into a small orifice. As the stem advances, flow reduces incrementally, allowing extremely fine control.

Key characteristics of a needle valve:

-

Linear stem movement

-

Small flow passage

-

High control resolution

-

Excellent sealing when properly designed

This design makes the needle valve ideal for applications where precision outweighs flow capacity.

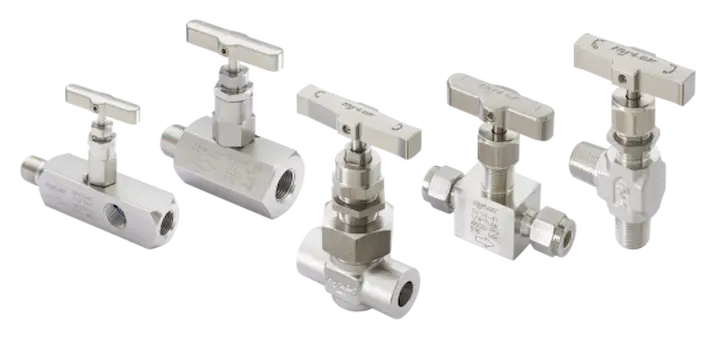

Common Types of Needle Valves

Straight Needle Valve

Used in straight-through piping where compact precision is required.

Angle Needle Valve

Redirects flow at 90°, reducing fittings and potential leak points.

High-Pressure Needle Valve

Designed with reinforced bodies and stems for demanding pressure conditions.

Instrumentation Needle Valve

Used in measurement systems for gases and liquids.

Case Studies from Vcore Valve

Case 1: Instrumentation Skid Upgrade

Replacing ball valves with stainless steel needle valves improved flow stability and eliminated pressure spikes.

Case 2: Chemical Dosing Line

A precision industrial needle valve reduced chemical waste by over 20% through accurate metering.

Data & Technical Comparison

| Valve Type | Flow Control Accuracy | Pressure Capability | Typical Use |

|---|---|---|---|

| Needle Valve | Excellent | High | Instrumentation |

| Ball Valve | Poor (Throttling) | Medium–High | Isolation |

| Globe Valve | Good | Medium | Regulation |

| Gate Valve | Very Poor | Medium | Isolation |

Market Trends & Industry Insights

-

Rising demand for high-pressure needle valves in hydrogen and test systems

-

Increased use of stainless steel needle valves in corrosive environments

-

Preference for compact, panel-mounted designs in automation systems

Usage & Selection Tips

-

Use needle valves only for flow regulation

-

Avoid frequent full open/close cycling

-

Select stainless steel for corrosive or high-pressure media

-

Verify stem tip geometry for sealing performance

-

Always check pressure and temperature ratings

Conclusion

A needle valve is not a substitute for an on/off valve—it is a precision tool. When selected correctly, it delivers stable flow control, protects sensitive equipment, and improves system efficiency. At Vcore Valve, we design needle valves for engineers who care about accuracy, reliability, and long-term performance.

If your system demands control rather than compromise, a properly specified needle valve is the answer.

FAQ – Needle Valves

Q1: What is a needle valve used for?

A needle valve is used for precise flow regulation in low-flow or high-pressure systems.

Q2: Can a needle valve be used for shut-off?

Yes, but it is not recommended for frequent isolation duty.

Q3: Are needle valves suitable for gas applications?

Yes, especially in instrumentation and control systems.

Q4: What materials are needle valves made from?

Common materials include brass, stainless steel, and alloy steel.

Q5: How do I choose the right needle valve size?

Selection depends on flow rate, pressure, temperature, and media.