Quick Summary

Balancing valves are critical components in fluid systems—especially HVAC and hydronic setups—designed to control and balance fluid flow, maintain consistent pressure, and ensure optimal temperature distribution.

Opening Scene: The Office That Couldn’t Get Comfort Right

Imagine walking into your office on a Monday morning: the reception area feels like a freezer, the marketing team’s corner is sweltering, and the meeting room alternates between the two—all while the HVAC system hums away, guzzling energy. The facilities manager has tried adjusting thermostats, checking filters, and even calling in a technician, but nothing sticks. Sound familiar? Chances are, the culprit is an unbalanced hydronic system—and the solution is a well-selected balancing valve.

User Pain Points

Uneven Temperature Distribution

In unbalanced systems, water flows to the path of least resistance, leaving some areas underheated or overcooled.

Wasted Energy & High Operating Costs

Unbalanced HVAC systems force pumps to work harder to compensate for flow issues, increasing energy consumption by up to 30%. Add frequent maintenance calls for overworked components, and operational costs spiral out of control.

System Instability & Shortened Lifespan

Fluctuating pressures and flow rates cause excessive wear on boilers, radiators, and fan coil units. Erosion, water noise, and premature component failure become common, leading to costly replacements and downtime.

Solutions & Recommendations

Choose the Right Type of Balancing Valve

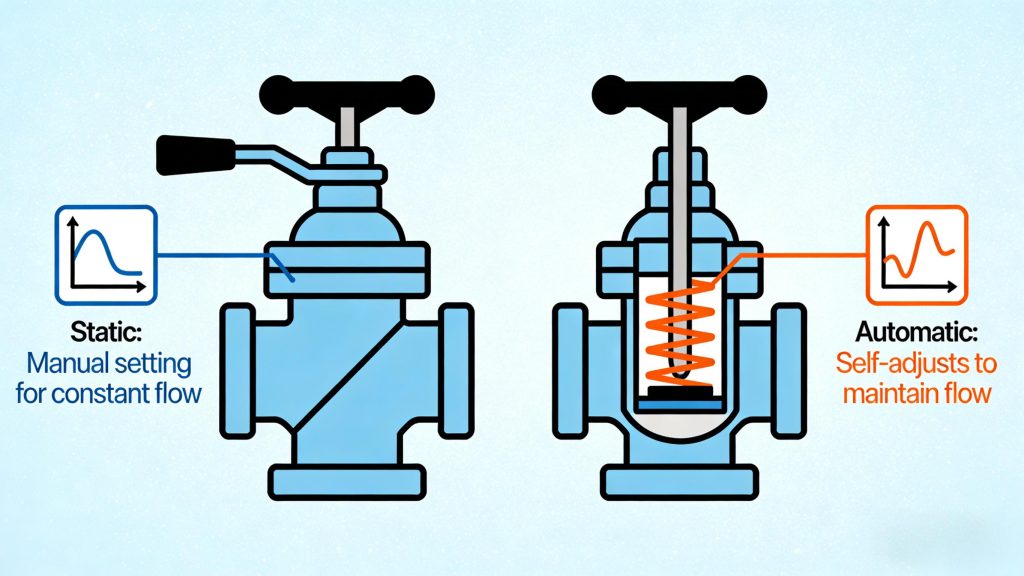

Select a balancing valve tailored to your system’s needs: static valves for steady, full-load conditions, automatic valves for variable loads, or PICVs for all-in-one control in complex setups.

Prioritize Professional Sizing & Installation

Valve size directly impacts performance. Use manufacturer sizing charts or consult a technical specialist to match the balancing valve to your pipe diameter and required flow rate.

Implement Regular Maintenance & Calibration

Even the best balancing valve needs upkeep. Schedule periodic checks to verify settings, clean components, and recalibrate if system demands change. Static valves may need manual adjustments, while automatic valves require inspection of moving parts.

Case Study: Industrial Facility Cuts Energy Costs by 22%

A mid-sized manufacturing plant in Birmingham struggled with uneven heating across its 50,000 sq. ft. facility. Workers in the assembly area complained of cold spots, while the warehouse overheated. After a system audit, technicians installed static balancing valves on each branch line and calibrated them using smart test equipment. Within three months, the plant’s energy consumption dropped by 22%, saving over £21,000 annually. Temperature consistency improved, reducing worker complaints and boosting productivity.

Data & Scientific Analysis: Balancing Valve Types Compared

| Feature | Static Balancing Valve | Automatic Balancing Valve | Pressure-Independent Control Valve (PICV) |

| Operation | Manual adjustment | Self-adjusting | Pressure-independent + flow control |

| Load Suitability | Full-load (2-3% of operation) | Variable loads | All load conditions |

| Energy Efficiency | High (low energy use) | Very high (reduces overpumping) | Highest (optimizes flow + pressure) |

| Installation Cost | Lower | Moderate | Higher |

| Maintenance Needs | Periodic recalibration | Minimal | Low |

| Accuracy | Precise for low flow rates | Consistent across pressure changes | Exceptional (all-in-one regulation) |

| Ideal Application | Domestic hot water, power generation | HVAC systems, fan coil units | Complex hydronic setups, chilled beams |

Data sourced from HVAC Engineering Research Association (HERA) and manufacturer performance reports.

Trends & Market Insights

The global balancing valve market is projected to grow at a CAGR of 5.8% from 2024 to 2030, driven by the push for energy-efficient buildings and stricter carbon emission regulations in the UK and EU. Key trends include:

- Rising demand for smart balancing valves with IoT connectivity for remote monitoring.

- Adoption of PICVs in commercial buildings is due to their all-in-one functionality.

- Increased focus on environmentally friendly materials (e.g., low-lead components) to meet sustainability goals.

- Industrial sectors are investing in large-diameter balancing valves(10-12 inches) for hydronic system upgrades.

Usage Recommendations

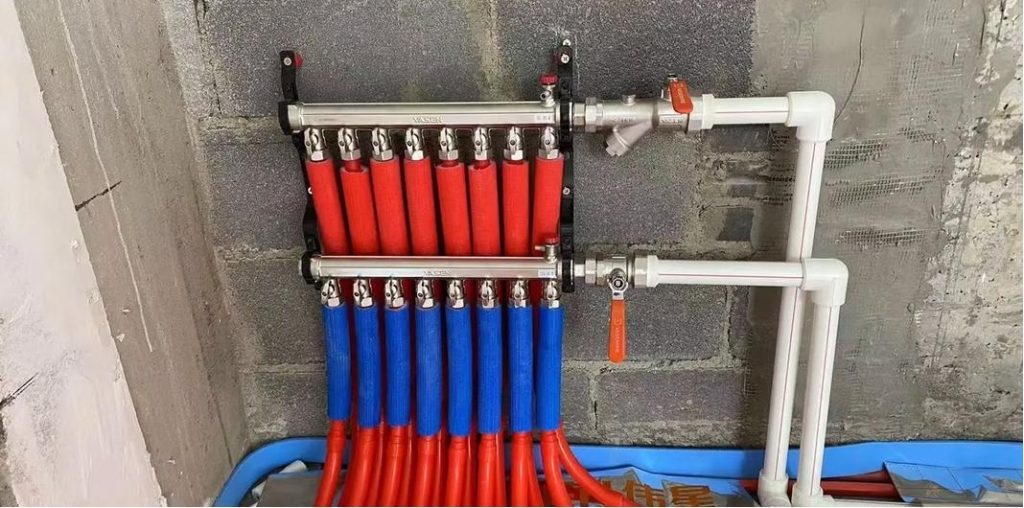

- Residential/Small Commercial: Opt for static balancing valves(DN 15-40) for cost-effectiveness and ease of maintenance. Ideal for in-floor heating and small HVAC systems.

- Large Commercial/Industrial: Automatic valves or PICVs are better for variable loads. Use in air handling units, heat exchangers, and chilled beam systems.

- Retrofits: Static valves are a budget-friendly upgrade for older systems; automatic valves offer long-term savings for high-demand setups.

- Noise Reduction: Automatic balancing valves minimize water noise and erosion, making them perfect for offices, hospitals, and schools.

Conclusion

A well-chosen and properly installed balancing valve is the unsung hero of efficient HVAC and hydronic systems. It solves temperature inconsistencies, slashes energy costs, and extends equipment lifespan—all while creating a more comfortable environment. Whether you’re upgrading a residential heating system or optimizing an industrial facility, the right balancing valve delivers tangible returns. For more expert insights, explore our Vavle Guide

FAQ

Q1: What is a balancing valve used for?

A: A balancing valve controls fluid flow and pressure in hydronic and HVAC systems, ensuring even temperature distribution, reducing energy use, and preventing equipment damage.

Q2: How do I choose the right size balancing valve?

A: Match the valve to your pipe diameter (DN) and required flow rate. Use manufacturer sizing charts or consult a specialist—incorrect size disrupts system balance.

Q3: Are static or automatic balancing valves better?

A: Static valves are cost-effective for full-load systems (e.g., domestic use). Automatic valves excel in variable-load setups (e.g., large HVAC) with self-adjustment.

Q4: Do balancing valves require maintenance?

A: Yes—static valves need periodic recalibration; automatic valves require occasional part inspections. Regular maintenance ensures optimal performance.

Q5: Can a balancing valve reduce energy costs?

A: Absolutely. By optimizing flow and preventing overpumping, balancing valves can cut energy consumption by 15-30%, as shown in industry studies.

Q6: What is the working temperature range for balancing valves?

A: Most valves operate between -20℃ and 120℃, suitable for water and ethylene glycol mixtures (common in hydronic systems).

Q7: Are balancing valves compatible with chilled beams?

A: Yes—balancing valves control chilled water flow to chilled beams, ensuring precise cooling and preventing under-/overcooling in commercial buildings.