Quick Summary

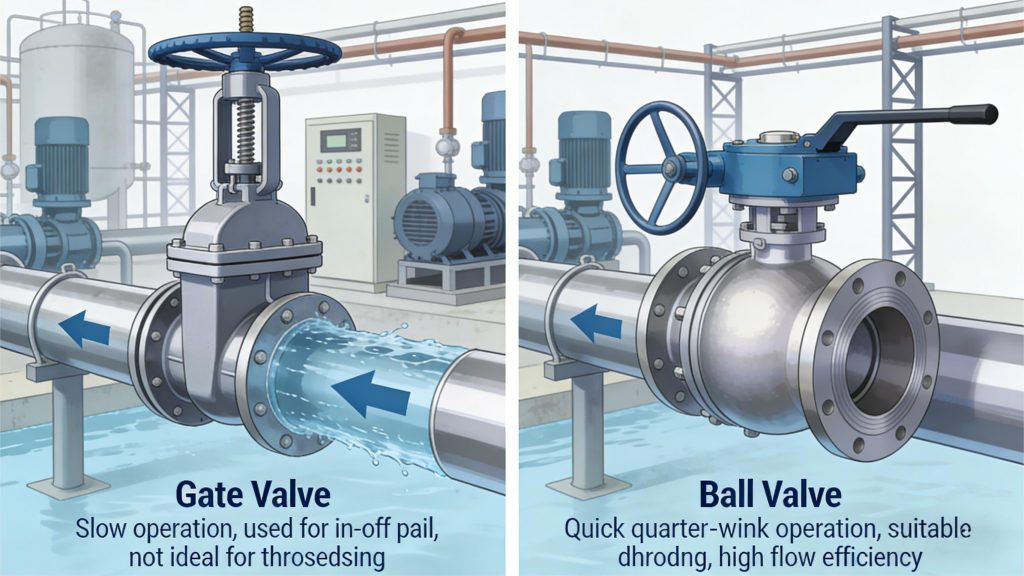

This guide breaks down 10 critical differences between gate valves and ball valves, covering design, operation, maintenance, and ideal uses. Whether you’re working on industrial pipelines or domestic plumbing, understanding these distinctions will help you select a reliable gate valve or ball valve that boosts system efficiency and cuts long-term costs.

Opening Scenario

Imagine you’re on a construction site, tasked with installing a water supply line for a new residential complex. The project manager asks: “Should we use a gate valve or ball valves here?” You pause—both control fluid flow, but choosing the wrong one could lead to leaks, frequent repairs, or even system failures. This is a common dilemma for engineers, plumbers, and contractors—and this guide is here to solve it.

User Pain Points

Pain Point 1: Uncertainty About Valve Selection

Many professionals struggle to tell when to use the gate valve vs. the ball valve. Picking the wrong type (e.g., a ball valve for a large-diameter water pipe) can cause poor flow control or premature wear.

Pain Point 2: High Maintenance Costs

Gate valves and ball valves have different upkeep needs. Neglecting regular maintenance for the gate valve (like monthly cleaning) leads to grime buildup, leaks, and costly replacements.

Pain Point 3: Slow Emergency Response

In situations like gas leaks or pipe bursts, slow-opening valves risk safety hazards. Gate valves require multiple handwheel turns to shut off, which is a problem when every second counts.

Solutions & Recommendations

Solution 1: Match Valves to Application

Use the gate valve for large-diameter pipelines (e.g., water supply or wastewater systems) where full flow or total shut-off is needed. Opt for ball valves for high-pressure, frequent-use scenarios (e.g., natural gas lines) thanks to their quick 90° operation.

Solution 2: Follow a Maintenance Schedule

For gate valves, clean internal and external parts monthly to prevent dirt buildup. For ball valves, perform a “shift cycle” (opening/closing the valve) every 3 months to check for leaks and avoid scale formation.

Solution 3: Prioritize Speed for Emergencies

Install ball valves in critical areas (e.g., chemical plants) where rapid shut-off is essential. Reserve a gate valve for systems that stay fully open/closed for long periods (e.g., irrigation lines) to avoid wear from frequent use.

Case Analysis

Case 1: Industrial Water Treatment Plant

A water treatment plant initially used ball valves for its 8-inch main pipelines. Within 6 months, the valves suffered seat erosion due to constant flow adjustment. The team switched to gate valves—their straight flow path minimized pressure drop, and the valves lasted 3 years with only monthly cleaning.

Case 2: Domestic Plumbing Upgrade

A homeowner replaced old gate valves under their sink with ball valves. The gate valve had leaked due to sediment buildup, but the ball valves’ tight PTFE seals stopped leaks entirely. Plus, the 90° handle made it easy to shut off water during minor repairs.

Data & Comparative Analysis

The table below compares gate valves and ball valves across key metrics, using data from industry standards and manufacturer specifications:

| Metric | Gate Valves | Ball Valves |

| Operation | Multi-turn (slow, >360°) | Quarter-turn (fast, 90°) |

| Sealing Performance | Good (prone to leakage over time) | Excellent (near-zero leakage with PTFE seats) |

| Pressure Range | Up to 16 bar (232 psi) for bronze models | Up to 320 bar (high-pressure stainless steel) |

| Temperature Range | -10°C to 120°C (bronze) | -40°C to 220°C (stainless steel) |

| Maintenance Needs | Monthly cleaning; frequent seat checks | 3-month shift cycles; minimal upkeep |

| Cost (1-inch size) | £20–£40 (brass) | £30–£60 (brass) |

| Ideal Applications | Water supply, wastewater, irrigation | Natural gas, chemicals, HVAC |

Trends & Market Insights

The global gate valves market is projected to grow at a 4.2% CAGR from 2024 to 2030, driven by demand from water infrastructure and oil/gas sectors (Grand View Research). Key trends include:

- Rising use of stainless steel gate valves for corrosion resistance in marine applications.

- Integration of smart actuators in gate valves to enable remote monitoring (reducing manual maintenance).

- Ball valves remain popular for compact systems, but the gate valve dominates large-diameter projects (≥6 inches) due to their low flow resistance.

Style & Usage Tips

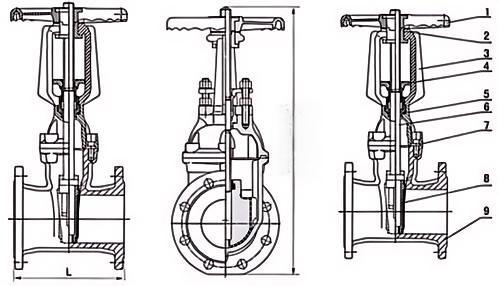

- For industrial settings, choose stainless steel gate valves for high-temperature fluids (e.g., steam) and bronze gate valves for low-pressure water lines.

- For Domestic Use: Brass gate valves are suitable for heating systems, but consider using ball valves under sinks or toilets for easy access.

- Installation: Ensure the gate valve is mounted vertically to prevent stem damage. Ball valves can be installed in any orientation, but avoid placing them near heat sources (to protect PTFE seals).

Conclusion & Call to Action (CTA)

Gate valves excel at full-flow control in large pipelines, while ball valves shine in high-pressure, fast-response scenarios. By matching the valve type to your project’s needs and following maintenance best practices, you’ll reduce downtime and costs.

Ready to choose the right gate valves? Visit our Gate Valves Product Page to browse brass, stainless steel, and bronze models. For personalized advice, contact our engineering team at [email protected]—we’ll help you find the perfect fit!

FAQ

Q1: Can gate valves be used for throttling (adjusting flow)?

A1: Gate valves have limited throttling ability. Partial opening causes valve seat wear and fluid turbulence—use them only for full open/closed positions.

Q2: Are gate valves suitable for potable water?

A2: A Brass or stainless steel gate valve is safe for potable water. Avoid bronze gate valves (high lead content) and clean them monthly to prevent sediment buildup.

Q3: How long do gate valves last?

A3: With proper maintenance (monthly cleaning), brass gate valves last 5–7 years, while stainless steel models can last 10+ years in industrial settings.

Q4: Can ball valves replace the gate valve?

A4: In small-diameter lines (≤2 inches), yes. But for large pipelines (≥3 inches), the gate valve is better—they handle higher flow rates with less pressure drop.

Q5: Does a gate valve need lubrication?

A5: Yes—apply silicone-based lubricant to the stem every 6 months to reduce friction. Avoid oil-based lubricants (they can damage rubber seals).

Q6: What causes a gate valve to leak?

A6: Common causes include worn seats, sediment in the valve body, or loose packing. Regular cleaning and seat inspections prevent leaks.

Q7: Are gate valves more expensive than ball valves?

A7: No—for the same size, gate valves are 20–30% cheaper. Ball valves cost more upfront but require less maintenance, making them cost-effective long-term.

Reference

- (2024). Ball Valve Vs. Gate Valve: What is the Difference? https://plumberstar.com/ball-valve-vs-gate-valve-what-is-the-difference/

- Grand View Research. (2024). Gate Valves Market Size Report, 2024–2030. https://www.grandviewresearch.com/industry-analysis/gate-valve-market

- NSW Valve. (2024). What is the Difference Between a Ball Valve and a Gate Valve? https://www.nswvalve.com/news/what-is-the-difference-between-ball-valve-and-gate-valve/