Quick Summary

Proper globe valve maintenance is one of the most cost-effective ways to extend valve service life, improve sealing performance, and avoid unplanned shutdowns. Despite their robust design, industrial globe valves are often exposed to harsh media, frequent throttling, and high temperatures—conditions that accelerate wear if maintenance is neglected. At Vcore Valve, we’ve seen that simple, well-timed maintenance actions can double the operational life of a globe valve. This guide explains how to do exactly that, step by step.

A Familiar Plant Scenario

“The valve was fine last year. Why is it leaking already?”

In many plants, globe valves are installed, commissioned, and then largely forgotten—until leakage, high torque, or flow control issues appear. The problem is rarely poor valve quality; it is almost always insufficient maintenance or incorrect operation.

Key User Pain Points

Premature Leakage

Seat and disc wear caused by poor throttling practices or debris leads to early sealing failure.

Rising Operating Torque

Lack of lubrication and stem contamination increase friction, making valves difficult to operate.

Shortened Valve Lifespan

Without regular inspection, small issues escalate into irreversible damage, forcing early replacement.

Practical Maintenance Solutions from Vcore Valve

Establish a Routine Inspection Plan

Regular inspection is the foundation of effective globe valve maintenance. Focus on:

-

Stem condition

-

Packing tightness

-

Body and bonnet leakage

-

Smoothness of operation

Apply Correct Lubrication

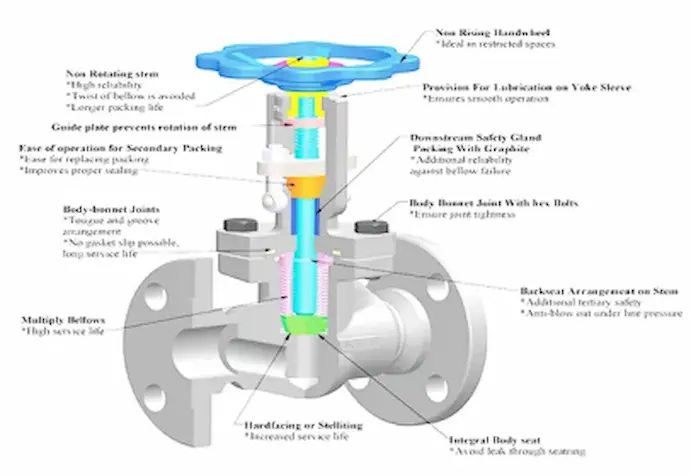

Proper lubrication of the stem and threads significantly reduces wear and operating torque, especially in steam globe valves and high-temperature services.

Operate the Valve as Designed

Globe valves are ideal for throttling—but excessive partial opening under high differential pressure accelerates seat erosion.

Real Maintenance Case Studies

Case 1: Steam System in a Power Plant

A forged steel globe valve experienced repeated stem seizure. Root cause analysis showed no stem lubrication over five years.

Solution: Implemented annual lubrication and packing inspection

Result: Zero stem-related failures over the next three years

Case 2: Chemical Processing Line

Frequent leakage occurred due to abrasive media damaging the seat.

Solution: Introduced scheduled internal inspection and improved flushing procedures

Result: Extended valve service life by over 40%

Technical Analysis: Why Maintenance Matters

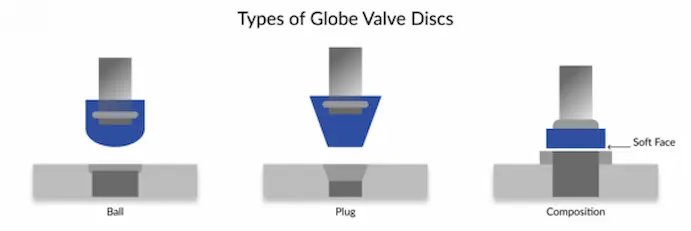

Globe valves rely on direct contact between the disc and seat to regulate flow. Over time:

-

Repeated throttling causes seat erosion

-

Debris scratches sealing surfaces

-

Thermal cycling stresses the packing and gaskets

Comparison: Maintained vs Neglected Globe Valves

| Factor | Properly Maintained | Poorly Maintained |

|---|---|---|

| Sealing performance | Stable | Rapid degradation |

| Operating torque | Consistent | Increasing |

| Leakage risk | Low | High |

| Service life | Extended | Severely shortened |

Engineering data shows that valves with basic preventive maintenance can last 30–60% longer than those left unattended.

Industry Trends and Market Insight

-

Plants are shifting from reactive to predictive valve maintenance

-

Increased use of condition monitoring for critical industrial globe valves

-

EPC contractors now specify maintenance-friendly valve designs

At Vcore Valve, we design globe valves with accessible packing, robust stems, and long-life sealing surfaces to simplify maintenance.

Best Practices for Globe Valve Use

-

Avoid excessive force when closing—tight is not always better

-

Fully open valves periodically to prevent seat imprinting

-

Replace packing before leakage becomes visible

-

Keep maintenance records for each valve

Conclusion

Extending the service life of a globe valve does not require complex procedures—just consistent, informed maintenance. Regular inspection, correct lubrication, and proper operation dramatically improve reliability and reduce the total cost of ownership.

If you’re looking for industrial globe valves designed for durability and easy maintenance, Vcore Valve is ready to support your projects with proven engineering solutions.

👉 Contact Vcore Valve today for maintenance advice or custom globe valve designs.

FAQs

How often should a globe valve be inspected?

For critical services, inspection every 6–12 months is recommended.

Can globe valves be used for continuous throttling?

Yes, but operating near the closed position under high pressure accelerates wear.

What causes stem leakage?

Worn packing, insufficient lubrication, or thermal cycling.

Is lubrication always required?

Yes, especially for manual globe valves in high-temperature or frequent-use applications.

When should packing be replaced?

At the first sign of leakage or increased operating torque.

Does Vcore Valve provide maintenance support?

Yes. We offer technical guidance and maintenance-friendly valve designs.

References

-

Valve Manufacturers Association (VMA) – Valve Maintenance Guidelines

-

ASME B16.34 – Valves: Pressure–Temperature Ratings

-

API 602 – Compact Steel Gate and Globe Valves

-

Engineering Toolbox – Valve Wear and Flow Control

-

ISO 5208 – Pressure Testing of Valves

-

OSHA – Mechanical Equipment Maintenance Safety

-

Vcore Valve Technical Library – Globe Valve Maintenance Guide