Quick Summary

In water and wastewater infrastructure, reliability is non-negotiable. Gate valves play a critical role in isolating pipelines, controlling flow during maintenance, and protecting treatment processes from disruption. From municipal water supply networks to wastewater treatment plants, these valves ensure safe, efficient, and long-term system operation. At Vcore Valve, we design gate valves for water and wastewater management with durability, tight shut-off, and easy maintenance in mind.

A Real-World Water System Scenario

“We need to shut down this section—now.”

In a water treatment plant, every second counts. A properly specified water gate valve allows operators to isolate pipelines smoothly without draining entire systems. When designed correctly, gate valves become silent guardians of public health and environmental safety.

Key User Pain Points

Leakage and Water Loss

Poor-quality or ageing valves often cause leakage, leading to non-revenue water and higher operating costs.

Difficult Maintenance and Isolation

Without reliable isolation valves, maintenance requires shutting down large sections of the network.

Corrosion and Sediment Build-Up

Water and wastewater environments accelerate corrosion and debris accumulation, shortening valve lifespan.

How Gate Valves Address These Challenges

Full-Bore, Unrestricted Flow

Gate valves provide minimal flow resistance when fully open, making them ideal for large-diameter pipelines.

Reliable Shut-Off for Maintenance

A well-designed wastewater gate valve ensures tight sealing, even after long periods without operation.

Adaptability to Harsh Media

Modern materials and coatings allow industrial gate valves to withstand corrosive wastewater and treated water.

At Vcore Valve, we focus on valve designs that reduce leakage while simplifying maintenance.

Case Studies and Practical Examples

Case 1: Municipal Water Supply Network

A city upgraded its old isolation valves to resilient seated gate valves.

Results:

-

Reduced leakage rates

-

Faster maintenance isolation

-

Improved service reliability

Case 2: Wastewater Treatment Plant

A treatment facility installed flanged gate valves with corrosion-resistant coatings.

Results:

-

Extended valve service life

-

Lower maintenance frequency

-

Stable operation in sludge-heavy lines

Engineering Data and Performance Comparison

Gate Valves vs Butterfly Valves in Water Systems

| Parameter | Gate Valves | Butterfly Valves |

|---|---|---|

| Flow resistance | Very low | Moderate |

| Shut-off capability | Excellent | Good |

| Large diameter suitability | Excellent | Very good |

| Maintenance isolation | Superior | Adequate |

For primary isolation in water pipelines, gate valves remain the preferred solution.

Design Features for Water and Wastewater Applications

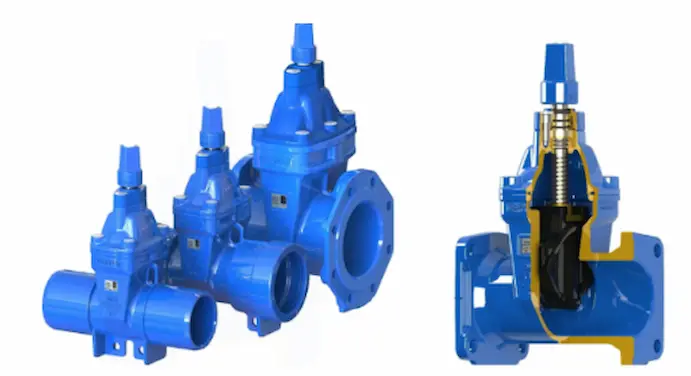

Resilient Seated Design

Rubber-lined gates provide tight sealing, even with minor debris present.

Corrosion-Resistant Materials

Epoxy coatings, stainless steel stems, and ductile iron bodies enhance durability.

Simple Gate Valve Operation

Linear movement reduces wear, extending operational life in pipeline gate valve applications.

Market Trends and Industry Insight

-

Growing investment in municipal water infrastructure

-

Rising demand for sluice gate valves in flood control and treatment plants

-

Increased preference for low-maintenance valve designs

As global water scarcity and infrastructure upgrades accelerate, gate valves for water supply remain essential components.

Installation and Usage Best Practices

-

Operate valves fully open or fully closed—avoid throttling

-

Schedule periodic cycling to prevent seizure

-

Verify flange alignment during gate valve installation

-

Select appropriate coatings for wastewater environments

Conclusion

From clean water delivery to wastewater treatment, gate valves are indispensable. Their simple design, reliable shut-off, and long service life make them the backbone of water infrastructure worldwide.

Vcore Valve supplies high-performance gate valves for water and wastewater management, engineered for real-world operating conditions.

👉 Contact Vcore Valve today to discuss your municipal or industrial water project.

FAQs

Why are gate valves commonly used in water systems?

They provide low flow resistance and reliable isolation.

Are gate valves suitable for wastewater?

Yes, when designed with corrosion-resistant materials and proper sealing.

What is a resilient seated gate valve?

A valve with an elastomer-coated gate for improved sealing.

Can gate valves be used for flow control?

No, they are designed for on/off isolation only.

How often should water gate valves be maintained?

Regular inspection and periodic operation are recommended.

Does Vcore Valve supply valves for wastewater plants?

Yes, Vcore Valve offers a full range of water and wastewater gate valves.

References

-

AWWA C509 – Resilient-Seated Gate Valves

-

AWWA C515 – Reduced Wall Gate Valves

-

ISO 2531 – Ductile Iron Pipes and Valves

-

World Health Organization – Water Safety Guidelines

-

Valve Manufacturers Association (VMA) – Water Valve Standards

-

Engineering Toolbox – Gate Valve Applications

-

Vcore Valve Water Industry Technical Data