🔍 Quick Overview

Brass valves are among the most widely used flow control components in plumbing and industrial systems—but how many types of brass valves are there, and which one is right for your application? At Vcore Valve, we regularly help buyers navigate this question. This guide explains the main types of brass valves, their structures, applications, advantages, and limitations, helping you choose confidently for water, gas, HVAC, and light industrial use.

🎬 Opening Scenario: A Common Buyer Question

“We need brass valves—but which type?”

“Ball, gate, globe, check… how different can they really be?”

In practice, choosing the wrong brass valve often leads to leakage, pressure loss, or premature wear. Let’s simplify the confusion.

⚠️ User Pain PointsToo Many Brass Valve Types, Too Little Clarity

Buyers often struggle to distinguish between brass ball valves, brass gate valves, and brass globe valves, especially when suppliers oversimplify specifications.

Misuse Causes Early Failure

Using the wrong brass valve type for throttling, isolation, or backflow prevention can shorten service life dramatically.

Material Assumptions

Not all brass alloys perform equally—incorrect alloy choice may lead to dezincification or corrosion.

✅ Solutions & Expert Recommendations

Understand Functional Categories

Each brass valve type is designed for a specific flow-control function, not interchangeability.

Match Valve Type to Media and Pressure

Water, gas, and HVAC systems impose different demands on brass valves.

Choose Certified Manufacturing

At Vcore Valve, our brass valves are produced with controlled alloy composition, CNC machining, and pressure testing.

🔧 Main Types of Brass Valves Explained

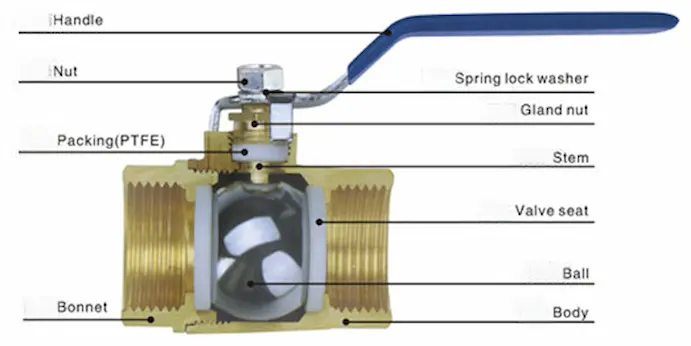

Brass Ball Valve

-

Quarter-turn operation

-

Excellent shut-off performance

-

Low pressure drop

-

Ideal for water, gas, and HVAC

Common Uses: Residential plumbing, industrial water lines

Brass Gate Valve

-

Linear gate movement

-

Full-bore flow when open

-

Not suitable for throttling

Common Uses: Isolation in water supply systems

Brass Globe Valve

-

Disc-and-seat throttling design

-

Precise flow regulation

-

Higher pressure drop

Common Uses: Flow control in heating and process lines

Brass Check Valve

-

Automatic backflow prevention

-

Available as swing, lift, or spring type

Common Uses: Pumps, vertical pipelines, HVAC systems

Brass Angle Valve

-

90-degree flow direction

-

Compact installation

Common Uses: Under-sink and fixture connections

Brass Stop Valve

-

Reliable shut-off with throttling ability

Common Uses: Water distribution and maintenance isolation

Brass Needle Valve

-

Fine flow adjustment

-

Small orifice design

Common Uses: Instrumentation and pressure control

📊 Data & Technical Comparison

| Valve Type | Flow Control | Pressure Drop | Typical Pressure | Main Application |

|---|---|---|---|---|

| Brass Ball Valve | On/Off | Very Low | Medium | Water, Gas |

| Brass Gate Valve | On/Off | Minimal | Medium | Isolation |

| Brass Globe Valve | Excellent | High | Medium | Regulation |

| Brass Check Valve | Automatic | Low | Medium | Backflow |

| Brass Needle Valve | Precision | High | Low–Medium | Instruments |

🧪 Case Studies from Vcore Valve

Case 1 – Residential Water System

Replacing gate valves with brass ball valves reduced leakage complaints by 60% and simplified maintenance.

Case 2 – HVAC Circulation Loop

Switching from ball valves to brass globe valves enabled accurate flow balancing and energy savings.

📈 Market Trends & Industry Insights

-

Rising demand for lead-free brass valves (e.g., CW617N, CW614N)

-

Increased use of brass ball valves in compact systems

-

Preference for EN-certified brass valves in EU markets

🛠 Usage & Selection Tips

-

Use brass ball valves for frequent operation

-

Avoid throttling with gate valves

-

Confirm temperature limits for hot water

-

Select dezincification-resistant brass for aggressive media

-

Always verify pressure rating

Conclusion

Understanding how many types of brass valves exist—and how each one performs—helps you avoid mismatches that lead to leakage, pressure imbalance, or early failure. At Vcore Valve, we support global buyers with dependable brass valve solutions, from residential plumbing to industrial water, gas, and HVAC systems.

If you need technical drawings, alloy recommendations, our engineering team is ready to assist with accurate selection and stable long-term supply.

❓ FAQ

Q1: How many types of brass valves are commonly used?

Typically 6–8 main types, depending on classification.

Q2: Are brass valves suitable for gas?

Yes, when certified and properly rated.

Q3: Which brass valve lasts the longest?

Brass ball valves generally offer the longest service life.

Q4: Can brass valves handle hot water?

Yes, within rated temperature limits.

Q5: Are all brass valves lead-free?

No. Always verify alloy compliance.