Understanding the Importance of Anti-Blowout Stems in Ball Valves

Quick Summary The anti blowout stems is one of the most important yet often overlooked safety features in industrial ball valves. When system pressure rises unexpectedly, a poorly designed stem can eject from the valve body—posing serious safety risks to personnel and equipment. At Vcore Valve, we consider the ball valve anti blowout stem a […]

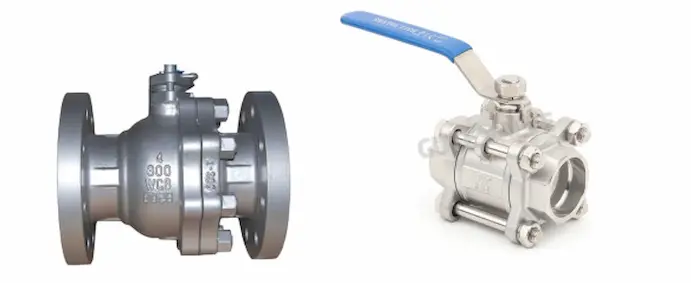

Soft Seat vs Metal Seat Ball Valve Explained

Quick Summary Discussing soft seat vs metal seat ball valve is one of the most critical topic in valve engineering. Seat design directly affects sealing performance, temperature resistance, service life and overall system reliability. At Vcore Valve, we see more failures caused by incorrect seat selection than by valve body defects. This guide explains the differences […]

API 607 vs API 6D Ball Valves: Key Differences Explained

Quick Overview API 607 vs API 6D ball valves is a popular topic—even for experienced engineers. While both standards are widely used in oil, gas, and industrial applications, they serve very different purposes. At Vcore Valve, we often help clients clarify this distinction before costly specification mistakes occur. A Real-World Engineering Scenario “Is this valve […]