The Full Port Ball Valve vs. Standard Ball Valves: Which Delivers Better Industrial Performance?

Quick Summary The Full Port Ball Valve (or full-bore valve) and standard ball valves (reduced port) are industrial staples—but their performance differs drastically. While standard valves restrict flow with smaller bores, the Full Port Ball Valve matches pipeline diameters, delivering unobstructed flow, lower pressure loss, and pigging compatibility. This guide compares their design, efficiency, and costs, helping […]

Why Low Torque Ball Valves Are Ideal for Automation

Quick Summary Automation systems demand precision, speed, and reliability—and valve torque plays a critical role. Low torque ball valves are specifically designed to minimise operating force, making them ideal for use with pneumatic and electric actuators. From chemical processing to oil & gas and water treatment, these valves improve control accuracy while reducing actuator size […]

PTFE vs PEEK: Choosing the Right Ball Valve Seal

Quick Overview Selecting the correct ball valve seal is just as important as choosing the valve body itself. Among the most common seat materials, PTFE vs PEEK dominate industrial applications. Each offers distinct advantages depending on pressure, temperature, and media conditions. In this guide, Vcore Valve explains the real differences between PTFE and PEEK, helping […]

Understanding the Importance of Anti-Blowout Stems in Ball Valves

Quick Summary The anti blowout stems is one of the most important yet often overlooked safety features in industrial ball valves. When system pressure rises unexpectedly, a poorly designed stem can eject from the valve body—posing serious safety risks to personnel and equipment. At Vcore Valve, we consider the ball valve anti blowout stem a […]

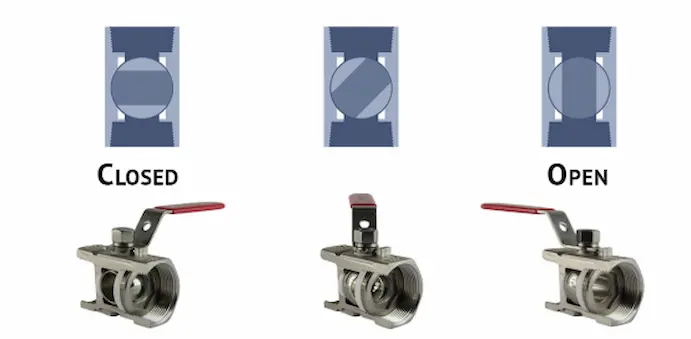

How to Properly Determine the Position of a Ball Valve

Quick Summary Knowing the exact ball valve position sounds basic, yet it remains one of the most common causes of operational errors in industrial systems. From unexpected pressure drops to complete line shutdowns, misjudging whether a valve is open or closed can be costly. At Vcore Valve, we regularly encounter this issue across oil & […]

Soft Seat vs Metal Seat Ball Valve Explained

Quick Summary Discussing soft seat vs metal seat ball valve is one of the most critical topic in valve engineering. Seat design directly affects sealing performance, temperature resistance, service life and overall system reliability. At Vcore Valve, we see more failures caused by incorrect seat selection than by valve body defects. This guide explains the differences […]

Ball Valves: Types, Uses & Buying Guide for Industrial & Home Applications

Quick Summary When it comes to controlling the flow of liquids, gases, or even solids in pipelines, ball valves stand out as one of the most reliable and versatile mechanical devices. A typical ball valve operates with a 90-degree handle rotation to open or close, aligning or blocking a ball-shaped disc’s hole with the flow path. This […]

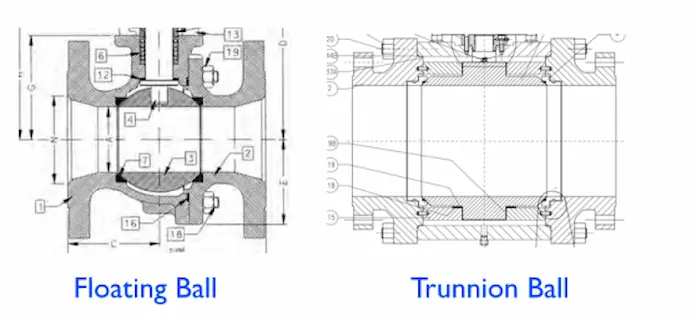

Floating vs Trunnion Ball Valve: What’s the Difference?

Quick Overview Floating vs trunnion ball valve is a critical comparing in pipeline design. Although both belong to the family of industrial ball valves, their internal structures, pressure handling, and operating torque differ significantly. In this guide, Vcore Valve explains the real engineering differences, ideal applications, and practical selection tips to help you avoid overspending—or […]