Best Valves for Seawater Applications

Quick Overview Seawater applications pose unique challenges for valve systems due to the corrosive nature of saltwater. Choosing the right valve material and type is crucial to ensuring long-term durability and performance. This article delves into the best valve solutions for seawater applications, focusing on corrosion resistance, performance, and cost-efficiency. Introduction: The Challenge of Seawater […]

Valves for Sugar Industry

Quick Overview In the sugar industry, the importance of selecting the right valves cannot be overstated. Valves play a critical role in ensuring smooth operations, controlling the flow of liquids and gases, and maintaining safety across various stages of sugar processing. This article explores the types of valves that are most commonly used in sugar […]

Long Pattern vs Short Pattern Ball Valve: Key Differences and Applications

Quick Overview Ball valves are a staple in industrial systems, offering precision control and durability. The main distinction between long pattern and short pattern ball valves lies in their design, which directly impacts their performance, durability, and application suitability. This guide helps you understand both valve types and make the right choice for your needs. […]

Efficient Valve Selection to Minimise Downtime: Best Practices and Tips

Quick Overview Choosing the right valve for your industrial system is crucial to minimizing downtime and ensuring smooth operations. Efficient valve selection and regular maintenance help prevent unplanned shutdowns, reduce maintenance costs, and ensure consistent flow control. In this article, we explore the importance of valve selection, the impact on downtime, and strategies to improve […]

What is the Difference Between Butterfly Valve and Butterfly Check Valve?

Quick Overview The butterfly valve and butterfly check valve are both commonly used in fluid systems, but they have distinct functionalities. Our butterfly valve is used primarily for flow regulation, while a butterfly check valve prevents backflow. This article will highlight the differences between these two valves, their use cases, and how to choose the […]

Flanged Valves vs. Screwed Valves: How to Choose the Right Valve for Your Application

Quick overview Flanged valves and Screwed valves are two of the most common valve types used in industrial applications. Both have distinct design features, applications, and installation requirements. Choosing the right valve type can improve system efficiency and reduce long-term maintenance costs. This article will explore the differences between these two valve types, helping you […]

Plug Valve vs Ball Valve: Key Differences & Applications

Quick Overview Understanding plug valve vs ball valve is crucial for engineers, plant operators, and pipeline designers. At Vcore Valve, we provide high-quality solutions tailored for various industrial applications. This guide explores functionality, design, and practical considerations for each valve type. Opening Scenario Imagine a chemical plant where flow control errors can lead to downtime or even […]

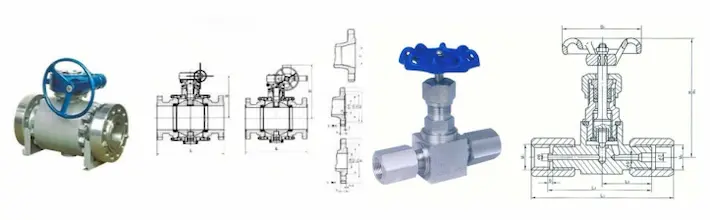

Needle Valve vs Ball Valve: Full Comparison Guide

Quick Summary When deciding between a needle valve and a ball valve, it’s important to understand how each type performs in terms of flow control, precision, pressure resistance and sealing performance. At Vcore Valve, we often see misapplications because buyers choose based on price or familiarity rather than function. This guide explains the key differences, […]

Globe Valves vs Gate Valves: Differences & Applications

Quick Summary Choosing between globe valves and gate valves is not just a matter of preference—it directly affects flow control accuracy, pressure loss, service life, and system safety. At Vcore Valve, we often see costly mistakes caused by selecting the wrong valve type. This guide clearly explains the structural, functional, and application differences to help […]

Vacuum Breaker vs Check Valve: Key Differences Explained

Quick Overview In fluid systems, backflow is not just inconvenient—it can be dangerous. Two common devices used to prevent it are vacuum breakers and check valves. While they often appear to serve the same purpose, their working principles, applications, and limitations are very different. At Vcore Valve, we regularly help customers choose between these two […]