Quick Summary

In high-pressure industrial environments, valve failure is not an option. Wedge gate valves are widely recognised as one of the most reliable isolation solutions for high-pressure systems, offering tight sealing, structural strength, and long-term durability. From oil and gas pipelines to power generation and chemical processing, these valves are engineered to withstand extreme pressure conditions. At Vcore Valve, wedge gate designs are developed to meet stringent international standards and real-world operating demands.

A Typical High-Pressure Scenario

“This line is running at full pressure—are we confident the valve will hold?”

In high-pressure service, confidence comes from proven design. A properly selected high pressure gate valve ensures safe isolation, even under severe pressure and temperature fluctuations.

Key User Pain Points

Leakage Under High Pressure

Standard valve designs may struggle to maintain tight shut-off when pressure increases.

Structural Stress and Deformation

High internal pressure can distort valve bodies and seats, reducing service life.

Maintenance Downtime

Frequent valve failures lead to unplanned shutdowns and increased operational costs.

Why Wedge Gate Valves Are the Solution

Superior Sealing Performance

The wedge-shaped gate creates a tight, pressure-assisted seal against the seats, making wedge gate valves ideal for high-pressure applications.

Robust Mechanical Strength

Designed with thicker bodies and reinforced components, industrial gate valves handle extreme loads without deformation.

Long-Term Reliability

Minimal seat wear during operation extends service intervals and reduces maintenance frequency.

At Vcore Valve, every wedge gate valve is engineered for consistent performance in demanding environments.

Case Studies and Application Examples

Case 1: Oil & Gas Transmission Pipeline

A pipeline operator specified API gate valves with a solid wedge design for a high-pressure crude oil line.

Results:

-

Zero leakage during pressure testing

-

Stable operation at peak pressure

-

Reduced maintenance intervention

Case 2: Power Generation Plant

A thermal power plant upgraded to pressure-sealing gate valves in high-temperature, high-pressure steam lines.

Results:

-

Improved sealing under thermal expansion

-

Extended valve service life

-

Enhanced operational safety

Engineering Data and Technical Comparison

Wedge Gate Valves vs Parallel Slide Gate Valves

| Feature | Wedge Gate Valves | Parallel Slide Gate Valves |

|---|---|---|

| High-pressure sealing | Excellent | Good |

| Pressure-assisted seating | Yes | Limited |

| Suitability for fluctuating pressure | High | Medium |

| Typical applications | Oil, gas, steam | Utility services |

The wedge mechanism makes wedge gate valves especially effective in high-pressure systems.

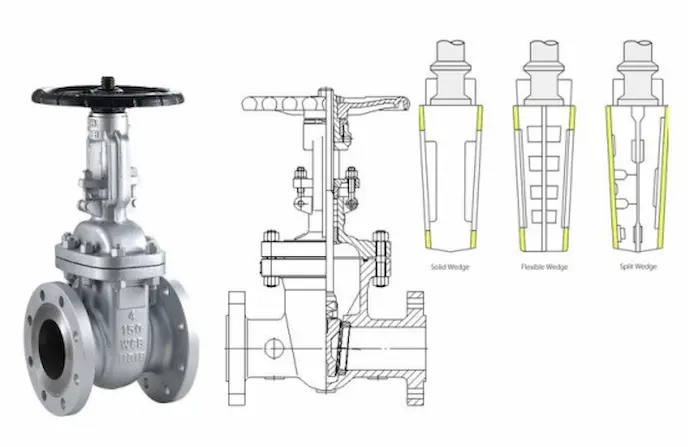

Design Types of Wedge Gate Valves

Solid Wedge

Best for clean, high-pressure services where temperature remains stable.

Flexible Wedge

Designed to compensate for thermal expansion and pipeline misalignment.

Split Wedge

Ideal for high-temperature and high-pressure systems with frequent cycling.

Vcore Valve offers multiple wedge configurations to suit different operating conditions.

Industry Trends and Market Insight

-

Growing demand for forged steel gate valves in high-pressure pipelines

-

Increased use of pressure seal bonnets in power and petrochemical plants

-

Stricter compliance with API and ASME standards

As operating pressures increase across industries, high-pressure gate valves remain essential for safe system design.

Installation and Operation Best Practices

-

Always operate gate valves fully open or fully closed

-

Avoid throttling in high-pressure service

-

Ensure correct orientation during gate valve installation

-

Perform periodic inspections under pressure

Internal DoFollow Links:

-

Gate Valve Product Range

-

Wedge Gate Valve Series

-

Forged Steel Valve Solutions

Conclusion

When operating under extreme pressure, valve selection matters. Wedge gate valves offer proven sealing performance, structural integrity, and long-term reliability for high-pressure systems.

Vcore Valve manufactures high-quality wedge gate valves designed for oil & gas, power generation, and industrial pipelines.

👉 Contact Vcore Valve today to discuss your high-pressure valve requirements or request technical documentation.

FAQs

What makes wedge gate valves suitable for high pressure?

Their wedge-shaped gate provides pressure-assisted sealing.

Are wedge gate valves suitable for high temperature?

Yes, especially flexible and split wedge designs.

Can wedge gate valves be used for flow control?

No, they are designed for isolation only.

What materials are used for high-pressure wedge gate valves?

Forged steel, carbon steel, alloy steel, and stainless steel.

How often should high-pressure gate valves be inspected?

Inspection frequency depends on pressure, temperature, and service conditions.

Does Vcore Valve supply API-compliant wedge gate valves?

Yes, Vcore Valve offers API gate valves for high-pressure applications.

References

-

API 600 – Steel Gate Valves for Petroleum and Natural Gas

-

API 602 – Forged Steel Gate Valves

-

ASME B16.34 – Valves: Pressure–Temperature Ratings

-

ISO 10434 – Bolted Bonnet Steel Gate Valves

-

Valve Manufacturers Association (VMA) – Gate Valve Design Guidelines

-

Engineering Toolbox – Gate Valve Types and Applications

-

Vcore Valve High-Pressure Valve Technical Data