🔍 Quick Overview

Choosing between a stop valve and a gate valve is not just a matter of habit—it directly affects system efficiency, safety, and service life. At Vcore Valve, we frequently see misapplications leading to leakage, pressure loss, or premature failure. This guide breaks down the core differences between stop valve vs gate valve, explains where each performs best, and provides clear, engineering-backed recommendations to help you make the right decision.

🎬 Opening Scenario: A Familiar Engineering Conversation

“The line pressure is unstable again.”

“But we installed new valves last year.”

“Yes—but they’re gate valves where stop valves should have been.”

If this sounds familiar, you are not alone. Many industrial issues originate not from poor manufacturing—but from incorrect valve selection.

⚠️ User Pain Points

Confusion Between Stop Valve vs Gate Valve

Many buyers assume both valves simply “open and close flow”. In reality, their internal structures and flow control characteristics differ significantly.

Incorrect Valve Selection Causes Energy Loss

Using a gate valve for throttling often leads to vibration, erosion, and pressure instability.

Maintenance and Downtime Risks

Poor valve choice increases wear, sealing failure, and unplanned shutdowns—especially in steam and high-pressure systems.

✅ Solutions & Expert Recommendations

✅ Understand Functional Design Differences

A stop valve (also known as a globe valve) is designed for flow regulation, while a gate valve is optimised for full open or full close isolation.

✅Match Valve Type to Application

Use stop valves where flow control is needed; use gate valves where minimal pressure loss is critical.

✅ Choose Industrial-Grade Manufacturing

At Vcore Valve, all stop and gate valves are manufactured with precision-machined seats, pressure-tested bodies, and material traceability.

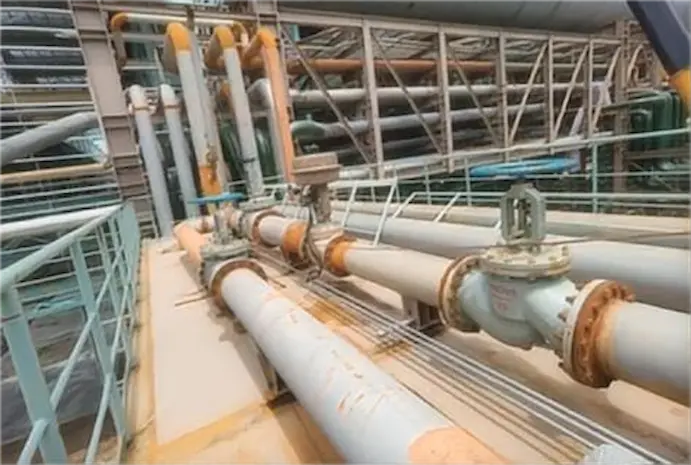

🔧 Stop Valve vs Gate Valve: Structural Comparison

Stop Valve (Globe Valve) Characteristics

-

Vertical disc movement

-

Excellent throttling capability

-

Higher pressure drop

-

Precise flow control

Gate Valve Characteristics

-

Linear gate movement

-

Minimal flow resistance when fully open

-

Not suitable for throttling

-

Ideal for isolation

📊 Data & Technical Comparison

| Feature | Stop Valve | Gate Valve |

|---|---|---|

| Flow Control | Excellent | Poor |

| Pressure Drop | High | Very Low |

| Throttling | Recommended | Not Recommended |

| Operation Cycles | Frequent | Infrequent |

| Common Media | Steam, water, oil | Water, oil, gas |

| Maintenance | Moderate | Low |

🧪 Case Study: Steam System Failure vs Optimisation

Case 1 – Incorrect Selection

A power plant used gate valves for steam regulation. Result:

-

Severe seat erosion

-

Pressure fluctuations

-

Valve replacement within 18 months

Case 2 – Corrected by Vcore Valve

Replaced with high-pressure stop valves:

-

Stable flow control

-

Reduced vibration

-

40% longer service life

📈 Market Trends & Industry Insights

-

Growing demand for energy-efficient flow control valves

-

Increased use of stop valves in automation systems

-

Rising preference for forged steel gate valves in oil & gas

According to industry standards such as ASME B16.34 and ISO 5208, correct valve application significantly reduces lifecycle cost.

🛠 Usage & Selection Tips

-

Use stop valves for throttling and frequent operation

-

Use gate valves only fully open or closed

-

Avoid partial opening of gate valves

-

Confirm pressure class and material compatibility

-

Always follow flow direction marking on stop valves

✅Conclusion

Selecting between a stop valve vs gate valve is not about price—it’s about performance, safety, and longevity. At Vcore Valve, we help engineers and buyers select valves that actually match operating conditions.

👉 Contact Vcore Valve today to get expert guidance, drawings, and tailored valve solutions for your project.

❓ FAQ

Q1: Can a gate valve be used for throttling?

No. Gate valves are designed for full open or close only.

Q2: Why does a stop valve cause pressure drop?

Its flow path changes direction, increasing resistance.

Q3: Which valve lasts longer?

When correctly applied, both have long service life.

Q4: Is a stop valve better for steam?

Yes. Stop valves handle pressure and temperature fluctuations better.

Q5: Are stop valves more expensive?

Usually yes—but they reduce operational risk and maintenance cost.