Quick overview

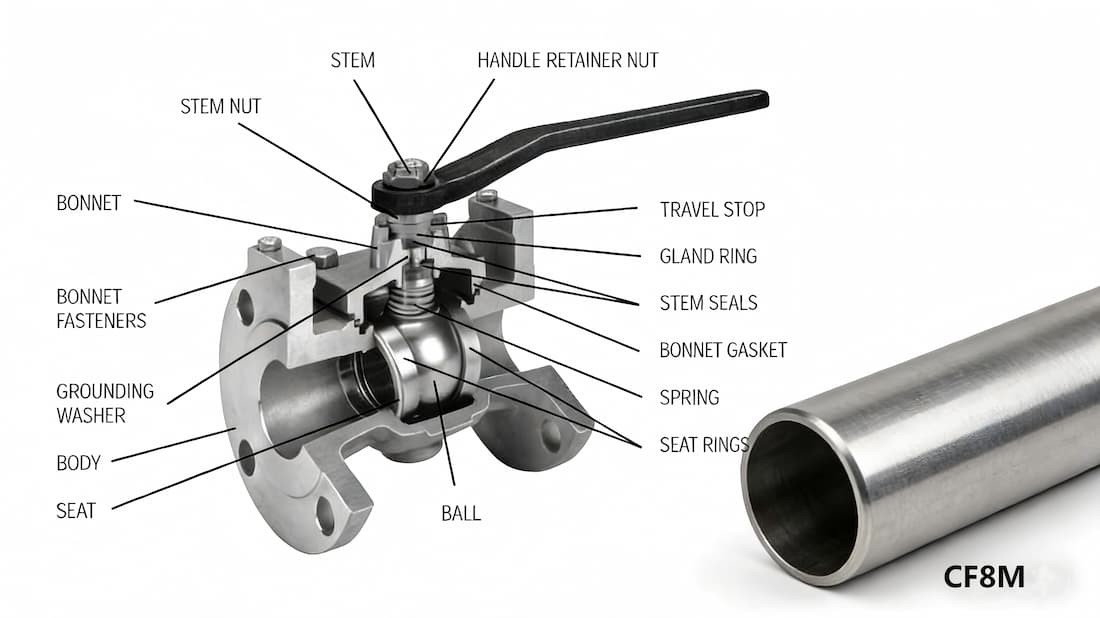

A CF8M ball valve is a stainless steel valve manufactured from ASTM A351 CF8M, equivalent to cast 316 stainless steel. Known for excellent corrosion resistance and reliable mechanical strength, CF8M ball valves are widely used in chemical processing, marine, food, and oil & gas industries. As a result, the CF8M ball valve is commonly used in chemical processing, water treatment, and food-grade industrial systems.

This article explains what CF8M really means, how it compares with other materials, and when it is the right—or wrong—choice.In industrial flow control systems, the CF8M ball valve is widely selected for its balance of corrosion resistance, strength, and long-term reliability, especially in floating ball valve designs used across industrial applications.

Opening Scenario

Imagine this scenario:

You are specifying a stainless steel ball valve for a mildly corrosive chemical line. The supplier asks, “Is CF8M acceptable?”

At first glance, CF8M sounds like just another stainless grade. In reality, choosing CF8M without understanding its limits can either save years of maintenance costs or create premature valve failure.

User Pain Points

Confusion Between CF8M and 316 Stainless Steel

Many buyers assume CF8M = forged 316 SS, which is not entirely accurate. CF8M is cast stainless steel, with slightly different mechanical properties.

Overestimating Pressure or Temperature Capability

CF8M offers good strength, but it is not designed for extreme high-pressure or high-temperature services, especially compared to carbon steel or duplex alloys.

Poor Material Selection for Chloride or Acid Media

While corrosion resistant, CF8M is not immune to pitting or crevice corrosion, especially in high-chloride environments.

Solutions and Practical Recommendations

Understand the CF8M Material Standard

CF8M complies with ASTM A351 CF8M, a cast stainless steel grade chemically similar to AISI 316 with added molybdenum for corrosion resistance.

This composition makes the CF8M ball valve particularly suitable for corrosive media and hygienic service conditions.

Match Material to Actual Service Conditions

CF8M performs best in:

-

Mild acids

-

Seawater environments

-

Food-grade applications

But not in: -

Concentrated hydrochloric acid

-

High-temperature steam above design limits

Choose the Right Valve Design

A CF8M floating ball valve is ideal for:

-

Medium-pressure systems

-

Tight shut-off requirements

-

Compact piping layouts

Case Examples

Case 1: Chemical Dosing System

A chemical plant replaced carbon steel valves with CF8M stainless steel ball valves, reducing corrosion-related leakage by over 60% within one year.

Case 2: Marine Cooling Water Line

CF8M ball valves demonstrated stable perform

ance in saltwater exposure, outperforming CF8 alternatives with lower molybdenum content.

Data, Scientific Comparison, and Material Analysis

Chemical Composition

| Element | CF8M (%) |

|---|---|

| Chromium | 18–21 |

| Nickel | 9–12 |

| Molybdenum | 2–3 |

| Carbon | ≤0.08 |

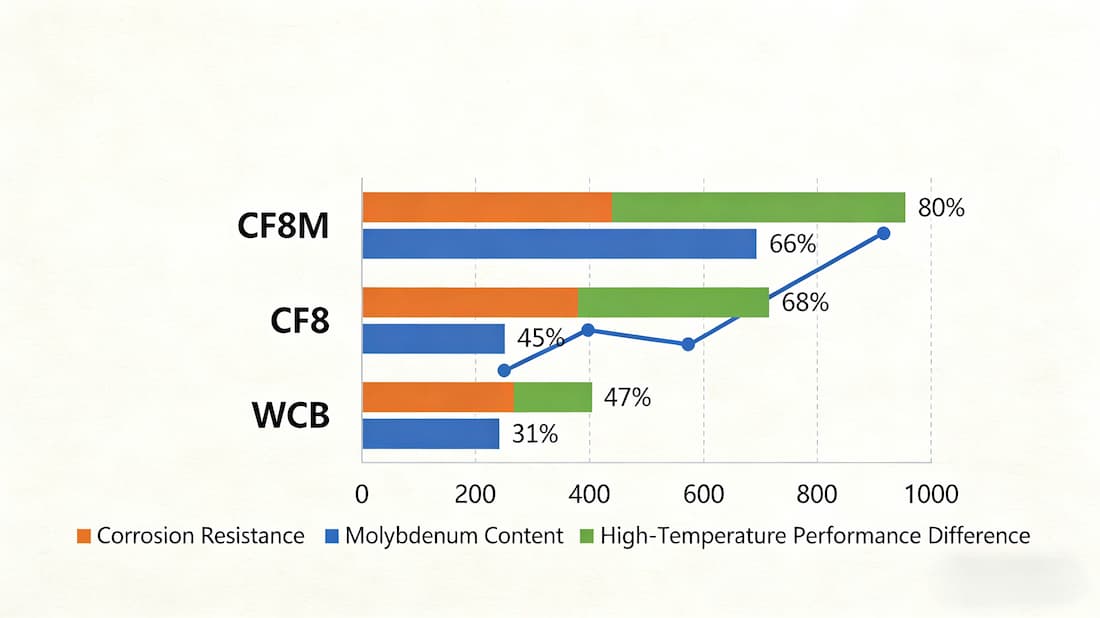

CF8M vs CF8 vs WCB

| Property | CF8M | CF8 | WCB |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Poor |

| High Temp Strength | Medium | Medium | High |

| Cost | Higher | Medium | Low |

Note: From a material perspective, choosing a CF8M ball valve offers a clear advantage when corrosion resistance is a priority over cost.

Market Trends and Industry Insights

-

Growing demand for corrosion-resistant ball valves in water treatment

-

Increased use of CF8M floating ball valves in food & beverage

-

Engineers increasingly favour material-specific specifications instead of generic “SS valves”

Usage and Selection Tips

-

Always confirm the pressure class and temperature rating

-

Avoid CF8M in high chloride concentration >200 ppm

-

Specify seat material (PTFE, RPTFE, PEEK) carefully

-

For automation, ensure the stem strength matches the actuator torque

Conclusions and Call to Action (CTA)

A CF8M ball valve offers an excellent balance between corrosion resistance, cost, and availability—when applied correctly. For demanding environments, selecting a properly specified CF8M ball valve is a practical way to reduce maintenance risks and extend service life.Understanding its material limits is essential for long-term reliability.

👉 Need help selecting the right stainless steel ball valve for your application?

Contact Vcore Valve engineering team for professional support.

FAQ

Q1: What does CF8M mean?

CF8M is a cast stainless steel grade under ASTM A351, equivalent to 316 stainless steel with molybdenum.

Q2: Is CF8M suitable for seawater?

Yes, CF8M performs well in seawater, though extreme chloride levels require caution.

Q3: CF8M vs 316 forged stainless steel?

CF8M is cast; 316 is forged. Mechanical strength and impact resistance may differ.

Q4: Can CF8M be used for high pressure?

It is suitable for medium pressure, but not extreme high-pressure systems.

Q5: Is CF8M food-grade?

Yes, CF8M is commonly used in food and beverage processing.

Q6: Does CF8M resist all acids?

No. It resists mild acids but not strong or concentrated acids.

References

-

ASTM A351 / A351M – Standard Specification for Austenitic Steel Castings

Defines chemical composition and mechanical requirements for CF8M stainless steel used in pressure-containing valve components. -

ASM International – Cast Stainless Steel Grades and Applications

Provides comparative analysis of CF8, CF8M, and related austenitic stainless steel grades in industrial equipment. -

Valve World Magazine – Material Selection Considerations for Ball Valves

Discusses how material grades influence corrosion resistance, service life, and operational reliability. -

AZoM Materials – CF8M Stainless Steel Properties and Industrial Use

Technical overview of CF8M material characteristics and typical industrial applications.