1️⃣ Quick Overview

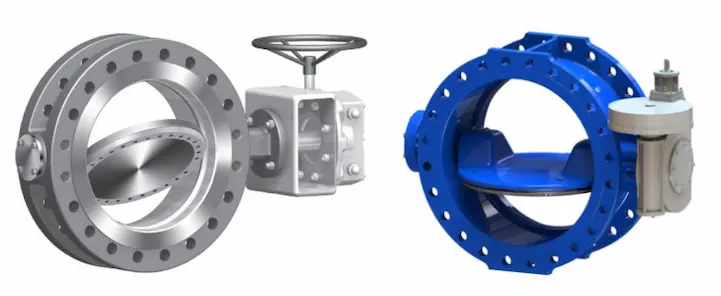

Discussing double offset vs triple offset butterfly valve is not just a matter of price—it directly affects sealing reliability, service life, and operational safety. While both designs improve on traditional concentric butterfly valves, they serve very different duties. At Vcore Valve, we often see incorrect valve selection causing premature leakage or over-specification. This guide explains the real differences, practical use cases, and how to choose wisely.

2️⃣ Opening Scenario: A Familiar Engineering Dilemma

“Both suppliers say their valve is zero leakage. One is double offset, one is triple offset. Why is the price gap so large?”

This is a question our engineers hear weekly from EPC contractors and plant managers. The short answer: the sealing philosophy is completely different, even though both valves look similar on the outside.

3️⃣ User Pain Points

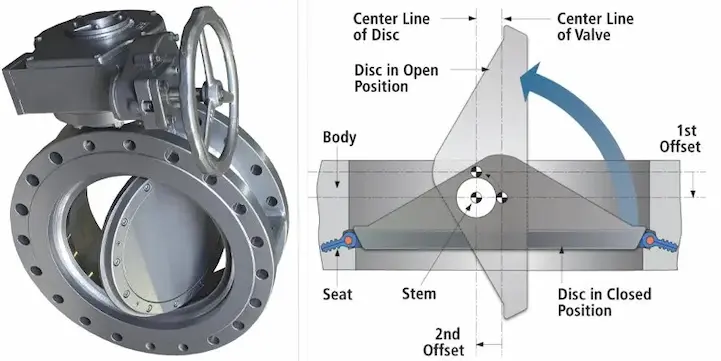

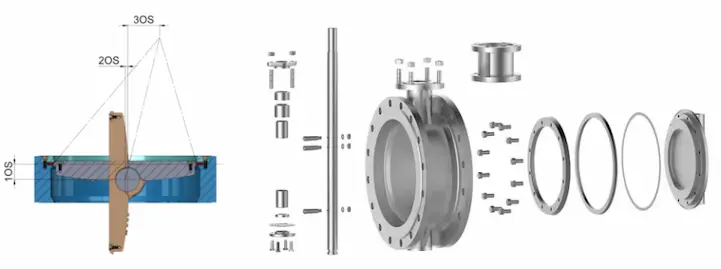

❌ Pain Point 1: Confusing Offset Terminology

Many buyers understand quarter-turn operation but struggle to visualise what “double” or “triple” offset actually means in operation.

❌ Pain Point 2: Leakage After Installation

Using a double offset butterfly valve in high-temperature or critical isolation service often leads to seat wear and leakage over time.

❌ Pain Point 3: Overpaying for Unnecessary Performance

Some systems do not require metal-to-metal sealing, yet end up with costly triple offset butterfly valves without clear benefit.

4️⃣ Solutions & Recommendations

✅ Solution 1: Match Sealing Type to Service

Soft-seated designs work well for clean, moderate services. Metal-seated designs are essential for high temperature, pressure, or fire-safe requirements.

✅ Solution 2: Consider Life-Cycle Cost, Not Unit Price

A cheaper valve with frequent maintenance often costs more than a premium valve over its service life.

✅ Solution 3: Consult Valve Specialists Early

At Vcore Valve, we review media, temperature, pressure, and operation cycles before recommending any butterfly valve design.

5️⃣ Case Study Examples

🏭 Case 1: District Heating Network

A European heating system replaced leaking soft-seated valves with double offset butterfly valves, improving service life while keeping costs under control.

🔥 Case 2: Refinery Emergency Isolation

A refinery required fire-safe, zero leakage isolation. Only triple offset butterfly valves with laminated metal seats met API and safety standards.

6️⃣ Technical & Scientific Comparison

| Feature | Double Offset Butterfly Valve | Triple Offset Butterfly Valve |

|---|---|---|

| Offset Design | Shaft offset + disc offset | Shaft + disc + conical seat |

| Seat Type | Soft seat or resilient | Metal-to-metal |

| Leakage Class | Typically Class VI (soft seat) | Zero leakage (metal seat) |

| Temperature Range | Up to ~200°C | Up to 600°C+ |

| Fire Safe | Limited | Yes |

| Torque | Moderate | Higher but predictable |

| Cost | Medium | Higher |

Key takeaway:

The third offset eliminates friction during operation, allowing true cam-action sealing, which is why triple offset valves excel in severe services.

7️⃣ Market Trends & Industry Insights

-

Growing demand for metal seated butterfly valves in energy and petrochemical projects

-

EPCs increasingly specify triple offset butterfly valves for critical isolation

-

Lifecycle reliability now outweighs initial cost in valve procurement strategies

8️⃣ Selection & Usage Guidelines

Choose a double offset butterfly valve if:

-

Media is clean

-

Temperature and pressure are moderate

-

Tight shut-off is required without metal sealing

Choose a triple offset butterfly valve if:

-

High temperature or thermal cycling is present

-

Fire-safe or zero leakage is mandatory

-

Valve failure carries high operational risk

Our engineering team at Vcore Valve assists with torque calculations, actuator sizing, and material selection.

9️⃣ Conclusion

There is no “better” valve—only the right valve for the application. Understanding the difference between double offset vs triple offset butterfly valves prevents leakage, downtime, and unnecessary cost.

👉 Contact Vcore Valve today for expert valve selection support or custom butterfly valve solutions tailored to your project.

🔟 FAQs

Q1: Is a triple offset butterfly valve always better than double offset?

No. Triple offset valves are designed for severe services, while double offset valves are more economical for moderate conditions.

Q2: Can double offset butterfly valves achieve zero leakage?

They can achieve tight shut-off with soft seats, but metal-to-metal zero leakage is exclusive to triple offset designs.

Q3: Are triple offset valves suitable for throttling?

They are primarily designed for isolation, not continuous throttling.

Q4: Why do triple offset valves cost more?

Due to complex geometry, precision machining, and metal sealing components.

Q5: Does Vcore Valve manufacture both types?

Yes. Vcore Valve supplies both double offset and triple offset butterfly valves with customised materials and standards.

Reference

-

API 609 – Butterfly Valves

-

ISO 5752 – Metal-Seated Valve Standards

-

Industrial Valve Manufacturer Guidelines

-

Vcore Valve Engineering Selection Manual