Quick Summary

A metal seated ball valve is widely used in high-temperature, high-pressure and abrasive media applications where soft seats fail rapidly. However, many users still encounter leakage, excessive torque or premature wear. At Vcore Valve, we see most failures are not design flaws—but application mismatches or improper operation. This article breaks down the most common faults, their root causes and practical solutions.

A Real Workshop Scenario

“The valve is metal-seated—why is it leaking already?”

“It survives 400°C, but not improper operation.”

This conversation happens more often than you’d expect. Metal seats improve durability, but they don’t forgive mistakes.

Common User Pain Points

Unexpected Leakage After Short Service Time

Users assume metal seats mean zero leakage under all conditions.

Excessive Operating Torque

Actuators struggle, manual operation becomes unsafe.

Rapid Seat or Ball Wear

Abrasive media accelerates damage when valve selection is incorrect.

Practical Solutions and Engineering Advice

Understand the Role of Metal Seats

Metal seating improves resistance, not immunity.

Match Coating and Materials to Media

Seat and ball coatings must suit temperature, pressure and particle size.

Follow Correct Operation Procedures

Partial opening under abrasive flow is a known valve killer.

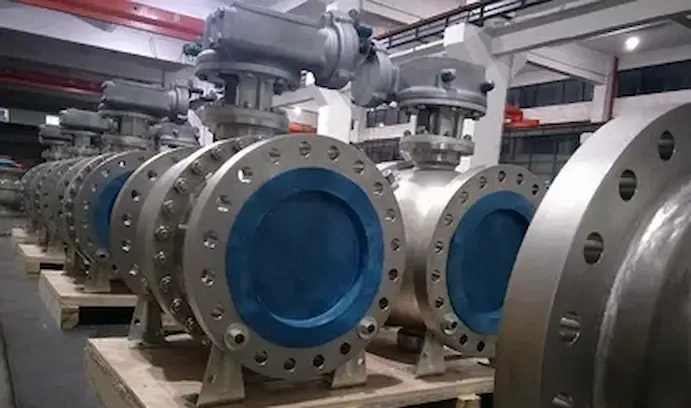

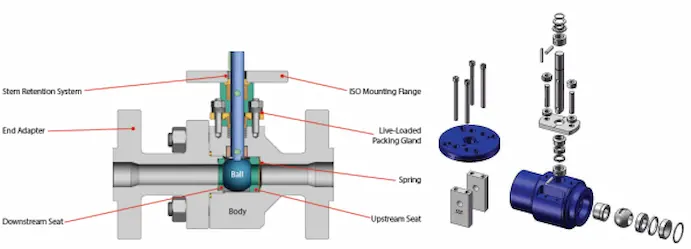

What Is a Metal Seated Ball Valve?

Our metal seated ball valve uses metal-to-metal contact between the ball and seat, often enhanced by hard-facing coatings such as tungsten carbide or chromium carbide.

Typical Advantages

-

High temperature resistance

-

Suitable for abrasive and corrosive media

-

Longer life in severe service

-

Stable performance under pressure

Common Faults in Metal Seated Ball Valves

Leakage at Closed Position

Symptoms:

-

Media passing through when fully closed

-

Failure in tight shut-off tests

Root Causes:

-

Seat or ball surface damage

-

Foreign particles trapped in sealing area

-

Improper seat loading design

Solutions:

-

Improve surface hardness and finish

-

Install upstream filtration

-

Use spring-loaded metal seats

Excessive Operating Torque

Symptoms:

-

Actuator overload

-

Manual operation becomes difficult

Root Causes:

-

High friction from metal-to-metal contact

-

Inadequate lubrication

-

Incorrect valve sizing

Solutions:

-

Optimise seat geometry

-

Use low-friction hard coatings

-

Select properly sized actuators

Premature Wear of Ball or Seat

Symptoms:

-

Loss of sealing integrity

-

Visible scoring or erosion

Root Causes:

-

Abrasive particles under throttling conditions

-

Valve operated partially open

-

Incorrect material pairing

Solutions:

-

Avoid throttling unless valve is designed for it

-

Use hardened coatings

-

Select eccentric or V-port designs when needed

Technical Comparison: Metal vs Soft Seated Ball Valves

| Parameter | Metal Seated Ball Valve | Soft Seated Ball Valve |

|---|---|---|

| Temperature range | Up to 500°C+ | Typically <200°C |

| Abrasion resistance | Excellent | Poor |

| Leakage class | Low but not zero | Bubble-tight |

| Operating torque | Higher | Lower |

| Service life (severe duty) | Long | Short |

Case Study: Slurry Pipeline Application

A mining customer replaced soft seated ball valves every three months due to slurry erosion.

Vcore Valve supplied metal seated ball valves with tungsten carbide coating.

Results:

-

Service life extended by over 4×

-

Maintenance downtime reduced significantly

-

Stable sealing performance achieved

Data-Based Performance Insights

Industry testing and field data indicate:

-

Hard-coated metal seats reduce wear by 60–80% in abrasive services

-

Incorrect throttling causes over 70% of premature failures

-

Proper material selection extends lifecycle far beyond soft-seat alternatives

Market Trends and Industry Insight

Current trends show:

-

Increased demand for metal seated ball valves in mining, power and petrochemical sectors

-

Preference for customised coatings over generic hard-facing

-

Growing focus on lifecycle cost rather than initial valve price

At Vcore Valve, most severe-service projects now default to metal seating solutions.

Usage and Operation Recommendations

Best practices include:

-

Use metal seated ball valves mainly for on/off service

-

Avoid prolonged throttling unless valve is designed for control

-

Ensure proper flushing during commissioning

-

Schedule regular inspection in abrasive systems

Conclusion

Metal seated ball valves are powerful tools—but only when used correctly. Understanding common faults and their real causes helps avoid unnecessary downtime and replacement costs.

At Vcore Valve, we engineer metal seated ball valves specifically for harsh industrial realities, not ideal laboratory conditions.

👉 Contact Vcore Valve for expert selection support or custom severe-service valve solutions.

FAQs

Q1: Why does a metal seated ball valve still leak?

Because metal seats prioritise durability over bubble-tight sealing.

Q2: Can metal seated ball valves be used for throttling?

Only if specifically designed for control applications.

Q3: Are metal seated ball valves suitable for abrasive media?

Yes, when paired with appropriate coatings and materials.

Q4: Why is operating torque higher than soft seated valves?

Metal-to-metal contact naturally increases friction.

Q5: How can seat wear be reduced?

Correct operation, filtration and suitable coatings are essential.

Q6: What industries use metal seated ball valves most?

Mining, power generation, oil & gas and chemical processing.