Quick Summary

Our rising stem gate valves is one of the most widely used isolation valves in industrial piping systems. Its defining feature—the externally visible stem movement—provides instant confirmation of valve position. For engineers, operators, and maintenance teams, this simple mechanical indicator translates into better safety, easier operation, and reduced operational risk. At Vcore Valve, rising stem designs remain a preferred choice for critical pipeline isolation across oil & gas, water, steam, and power industries.

A Familiar Plant Scenario

“Is the valve fully open or just halfway?”

In busy industrial environments, guessing valve position is not acceptable. With a rising stem gate valve, there is no guesswork—the stem tells the truth at a glance.

Key User Pain Points

Unclear Valve Position

Non-rising stem valves hide the stem movement, making it difficult to confirm whether the valve is open or closed.

Operational Safety Risks

Incorrect valve position can lead to pressure surges, equipment damage, or unsafe maintenance conditions.

Higher Maintenance Uncertainty

Without visual indication, troubleshooting valve-related issues becomes slower and less accurate.

How Rising Stem Gate Valves Solve These Problems

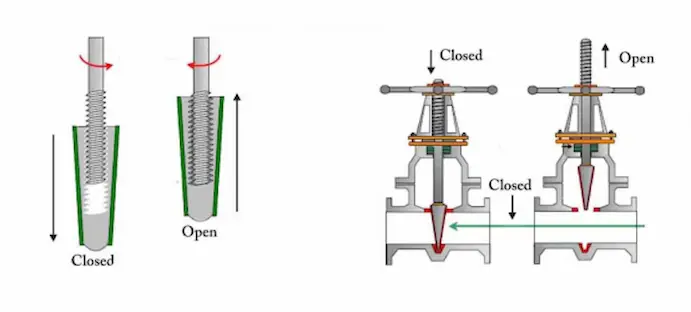

Clear Visual Position Indication

The stem rises when the valve opens and retracts when closed, acting as a natural valve stem indicator.

Reliable Gate Valve Operation

The stem and gate move linearly, reducing wear on seating surfaces and improving shut-off performance.

Simplified Maintenance Planning

Operators can visually verify valve status before maintenance, reducing human error.

At Vcore Valve, all rising stem gate valves are engineered to provide smooth stem movement and long service life.

Case Studies from Industrial Applications

Case 1: Oil & Gas Pipeline Isolation

An EPC contractor specified OS&Y gate valves for a crude oil pipeline.

Outcome:

-

Faster commissioning checks

-

Reduced operator training time

-

Improved safety compliance

Case 2: Water Treatment Facility

A municipal project upgraded old valves to flanged gate valves with rising stems.

Outcome:

-

Instant valve status confirmation

-

Lower maintenance errors

-

Improved operational reliability

Engineering Analysis and Design Comparison

Rising Stem vs Non-Rising Stem Gate Valves

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

|---|---|---|

| Valve position visibility | Excellent | Limited |

| Installation height | Requires more space | Compact |

| Maintenance clarity | High | Medium |

| Common applications | Oil, gas, steam | Underground pipelines |

From an engineering standpoint, rising stem gate valves are ideal where visibility and control matter more than compact installation.

Design Principles Behind Rising Stem Gate Valves

The gate valve design separates stem rotation from gate movement. As the handwheel turns, the stem rises or lowers without rotating the gate itself. This reduces friction on the gate and seats, extending valve life—especially important in industrial gate valves handling high pressure or temperature.

Market Trends and Industry Insight

-

Increasing preference for OS&Y gate valves in safety-critical pipelines

-

Strong demand from refineries and power plants

-

Continued use in above-ground pipelines where space allows

At Vcore Valve, rising stem gate valves are frequently specified in export projects due to their operational transparency and reliability.

Installation and Usage Recommendations

-

Ensure adequate vertical clearance for full stem travel

-

Lubricate stem threads regularly

-

Avoid using gate valves for throttling

-

Confirm flange alignment during gate valve installation

Conclusion

A rising stem gate valve offers more than simple on/off control—it provides visibility, confidence, and safety. For applications where valve position must be clearly known, rising stem designs are the logical choice.

Vcore Valve manufactures high-quality rising stem gate valves built to international standards and real-world operating conditions.

👉 Contact Vcore Valve today to discuss your project requirements or request technical support.

FAQs

What is a rising stem gate valve?

It is a gate valve where the stem moves up and down visibly to indicate valve position.

What does OS&Y mean?

OS&Y stands for Outside Screw and Yoke, a common rising stem design.

Are rising stem gate valves suitable for underground use?

Generally no, due to stem exposure and space requirements.

Can rising stem gate valves handle high pressure?

Yes, especially when designed as forged steel gate valves.

Do rising stem valves require more space?

Yes, vertical clearance is needed for stem travel.

Does Vcore Valve supply rising stem gate valves?

Yes. Vcore Valve offers a full range of rising stem gate valves in various sizes and materials.

References

-

API 600 – Steel Gate Valves for Petroleum and Natural Gas

-

ASME B16.34 – Valves: Pressure–Temperature Ratings

-

MSS SP-70 – Cast Iron Gate Valves

-

Valve Manufacturers Association (VMA) – Gate Valve Guidelines

-

Engineering Toolbox – Gate Valve Types and Operation

-

ISO 10434 – Bolted Bonnet Steel Gate Valves