Quick Overview

In high-risk industries such as oil & gas, petrochemical, and pipeline transmission, isolation is not optional—it is mission-critical. Double Block and Bleed (DBB) valves and Double Isolation and Bleed (DIB) valves are designed to provide enhanced safety, leak prevention, and maintenance confidence. This article from Vcore Valve explains how DBB and DIB valves work, their structural differences, and how to choose the right solution for demanding isolation applications.

A Common Site Conversation

“The line is isolated—but are we absolutely sure?”

That question is why DBB and DIB valves exist. In critical services, “probably sealed” is never good enough.

User Pain Points in Pipeline Isolation

Uncertain Isolation Safety

Single-seat valves cannot guarantee zero leakage during maintenance or shutdown.

Space and Cost Constraints

Traditional isolation requires multiple valves, fittings, and bleed points.

Compliance and Risk Exposure

Failure to meet API and safety standards can lead to downtime, penalties, or worse—accidents.

How DBB and DIB Valves Address These Challenges

True Redundant Isolation

Both DBB valves and DIB valves provide two sealing barriers with a bleed cavity in between.

Compact Valve Design

A single valve body replaces multiple isolation valves, reducing footprint and weight.

Improved Maintenance Confidence

Bleed ports allow operators to verify sealing integrity before intervention.

At Vcore Valve, DBB and DIB designs are engineered for safety-first operations.

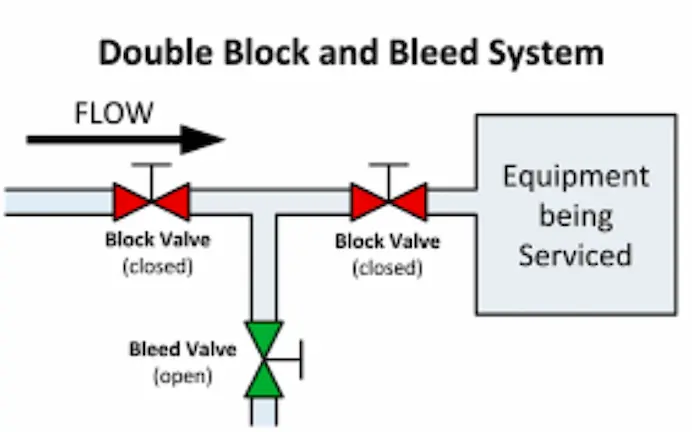

Understanding Double Block and Bleed (DBB) Valves

What Is a DBB Valve?

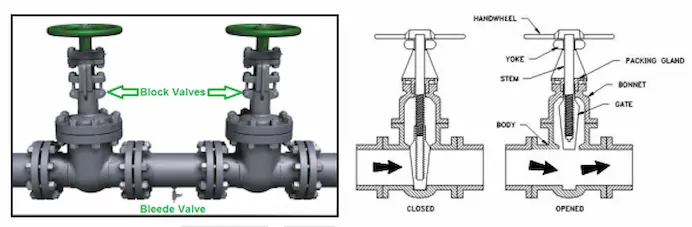

A double block and bleed valve features two independent sealing surfaces (blocks) and a bleed port located between them.

How a DBB Valve Works

-

Primary and secondary seals isolate upstream and downstream pressure

-

The bleed valve vents trapped pressure

-

Leakage past the first seal is safely released

Key Characteristics of DBB Valves

-

Two sealing elements rely on line pressure

-

Bleed confirms isolation integrity

-

Widely used in pipeline isolation valves

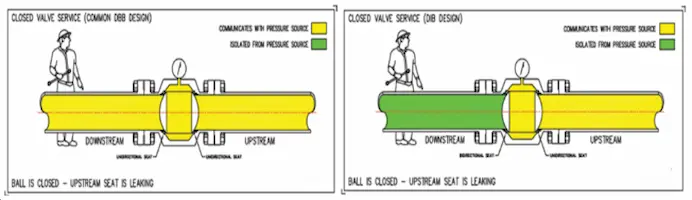

Understanding Double Isolation and Bleed (DIB) Valves

What Is a DIB Valve?

A DIB valve provides two independent isolation seals, each capable of sealing against pressure from either side.

How a DIB Valve Works

-

Each seat acts as a self-energising isolation barrier

-

The cavity between seats can be bled or monitored

-

Offers higher safety than standard DBB designs

DIB Type I vs Type II

-

DIB-1: Two bi-directional self-relieving seats

-

DIB-2: One bi-directional and one uni-directional seat

DBB vs DIB: Technical Comparison

| Feature | DBB Valve | DIB Valve |

|---|---|---|

| Isolation principle | Line-pressure dependent | Independent sealing |

| Leakage detection | Via bleed port | Via bleed port |

| Safety level | High | Very high |

| Compliance | API 6D | API 6D |

| Typical applications | Pipelines, manifolds | Critical isolation points |

This comparison explains why DIB valves are often specified for high-risk services.

Case Studies and Practical Applications

Case 1: Offshore Oil & Gas Platform

A DIB ball valve replaced a multi-valve isolation system.

Results:

-

Reduced leak risk

-

Faster maintenance

-

Improved compliance with safety audits

Case 2: Refinery Transfer Line

A DBB valve was selected for space-limited pipe racks.

Results:

-

Compact installation

-

Reliable isolation verification

-

Lower installation cost

Data, Standards, and Engineering Insight

Relevant Industry Standards

-

API 6D – Pipeline valves

-

ISO 14313 – Petroleum and natural gas valves

-

ASME B16.34 – Pressure-temperature ratings

Engineering Advantage

DBB and DIB valves reduce flange connections, which statistically account for a large percentage of leakage incidents in pressurised systems.

Market Trends and Industry Insight

-

Increased adoption of double isolation valves in LNG and hydrogen

-

Growing preference for DIB valves in critical safety zones

-

Integration with actuators and position feedback

-

Demand for fire-safe and low-emission designs

Isolation technology is moving toward fewer components, higher safety, and smarter monitoring.

Selection and Usage Recommendations

-

Choose DBB valves for standard isolation and space efficiency

-

Select DIB valves for hazardous, toxic, or high-pressure media

-

Always verify API 6D compliance

-

Consider actuation and monitoring requirements

Conclusion

Understanding how DBB and DIB valves work is essential for designing safer and more efficient isolation systems. While both offer enhanced protection, DIB valves provide the highest level of independent isolation for critical services.

At Vcore Valve, we design DBB and DIB ball valves that meet international standards and real-world operating demands.

👉 Contact Vcore Valve to select the right isolation solution for your application.

FAQs

What is the main difference between DBB and DIB valves?

DBB relies on line pressure for sealing, while DIB provides independent sealing barriers.

Are DBB and DIB valves covered by API 6D?

Yes, both designs are defined and regulated by API 6D.

Can DBB valves replace two separate isolation valves?

Yes, that is one of their main advantages.

Are DIB valves safer than DBB valves?

Generally yes, especially for critical or hazardous media.

Can DBB and DIB valves be actuated?

Absolutely—manual, pneumatic, and electric actuation are all common.

Does Vcore Valve supply API 6D certified DBB/DIB valves?

Yes, with full documentation and testing.

References

-

API Specification 6D – Pipeline Valves

-

ISO 14313 – Petroleum and Natural Gas Industries

-

ASME B16.34 – Valve Pressure Ratings

-

Valve Manufacturers Association (VMA)

-

Energy Institute – Process Safety Guidance

-

Engineering Toolbox – Valve Isolation Principles