Quick Overview

Our gear operated butterfly valve is a manually operated flow control solution designed for pipelines where valve size, pressure, or torque requirements exceed the limits of a simple hand lever. By using a worm gear mechanism, these valves allow smooth, precise operation with minimal effort. At Vcore Valve, gear operated butterfly valves are engineered for durability, safety, and long-term performance across water, wastewater, power, and industrial process systems.

A Practical Site Scenario

“The valve is too large to operate safely by hand.”

“Then a gear-operated solution is the only sensible answer.”

This is a common moment in large-diameter or high-pressure systems, where manual butterfly valves with levers simply cannot deliver controlled, safe operation.

User Pain Points in Manual Valve Operation

Excessive Operating Torque

Large valves require high torque, making lever operation unsafe or impractical.

Poor Flow Control Accuracy

Quick lever movement can cause water hammer or unstable process conditions.

Operator Safety Concerns

Sudden movement or kickback during operation can lead to injury.

Practical Solutions and Engineering Recommendations

Worm Gear Reduction for Torque Control

A gear operated butterfly valve uses mechanical advantage to reduce operating force dramatically.

Controlled and Gradual Operation

Gear mechanisms allow slow, precise opening and closing, improving system stability.

Lockable and Positionable Design

Most gearboxes include position indicators and locking features to prevent accidental operation.

What Is a Gear Operated Butterfly Valve?

Our gear operated butterfly valve is a butterfly valve fitted with a worm gear gearbox instead of a hand lever. The gearbox converts multiple turns of the handwheel into controlled rotation of the valve disc, enabling smooth operation even on large diameter butterfly valves.

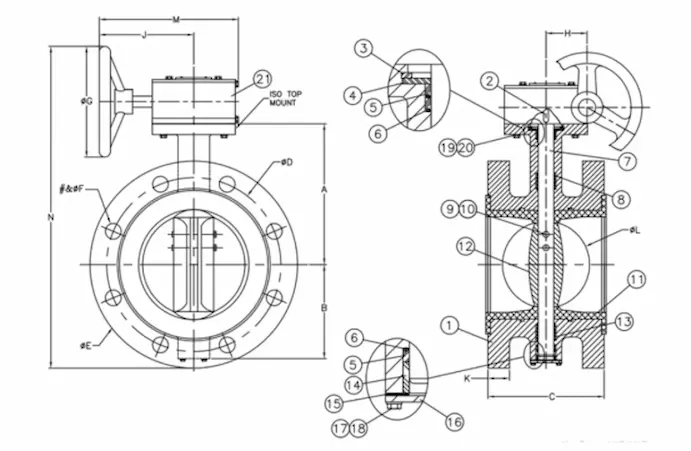

Main Components

-

Butterfly valve body

-

Disc and seat

-

Worm gear gearbox

-

Handwheel with position indicator

This design is widely used where automation is unnecessary but controlled manual operation is critical.

Gear Operated vs Lever Operated Butterfly Valves

| Feature | Lever Operated | Gear Operated |

|---|---|---|

| Suitable valve size | Small–medium | Medium–large |

| Torque handling | Limited | Excellent |

| Flow control | Basic | Precise |

| Operator safety | Moderate | High |

For pipelines above DN200 (8”), worm gear butterfly valves are often the preferred choice.

Types of Gear Operated Butterfly Valves

Wafer Type

Compact and lightweight, ideal for space-constrained pipelines.

Lug Type

Allows end-of-line service and easier maintenance.

Flanged Type

Provides maximum strength and alignment for heavy-duty applications.

Each configuration is available from Vcore Valve with tailored gear ratios.

Case Studies and Industry Examples

Case 1: Municipal Water Supply Network

Our DN600 gear operated butterfly valve was installed for mainline isolation.

Results:

-

Safe, single-operator control

-

Reduced risk of pipeline shock

-

Improved maintenance access

Case 2: Power Plant Cooling System

Metal seated gear-operated valves were used for high-temperature cooling water.

Results:

-

Reliable sealing

-

Smooth operation under thermal expansion

Engineering Data and Performance Analysis

Gearboxes typically provide reduction ratios between 20:1 and 80:1, depending on valve size and torque requirements. This significantly lowers the force required at the handwheel while maintaining disc stability.

Compared with lever operation, gear operation reduces operator effort by up to 70% in large-size valves, making it the preferred solution for industrial butterfly valves.

Market Trends and Industry Insight

-

Growing demand for large-diameter pipeline infrastructure

-

Continued use of manual valves in remote or power-limited sites

-

Increased focus on operator safety and ergonomic design

-

Preference for gear operation as an alternative to automation in low-cycle applications

Despite automation growth, gear operated butterfly valves remain essential in many industries.

Selection and Usage Recommendations

-

Choose resilient seated valves for water and HVAC systems

-

Select metal seated designs for high temperature or abrasive media

-

Confirm gearbox IP rating for outdoor installations

-

Ensure clear access to handwheel and position indicator

Conclusion

Our gear operated butterfly valve offers the perfect balance between manual simplicity and controlled operation. It delivers safety, precision, and reliability where lever operation is no longer practical.

At Vcore Valve, our gear operated butterfly valves are designed for demanding environments—robust gearboxes, precise machining, and proven sealing performance.

👉 Contact Vcore Valve today to select the right gear operated butterfly valve for your project.

FAQs

When should a gear operated butterfly valve be used?

When valve size or torque makes lever operation unsafe or difficult.

Can gear operated butterfly valves be locked in position?

Yes, most gearboxes include locking mechanisms or padlock features.

Are they suitable for throttling?

Yes, the gearbox allows precise flow adjustment.

What materials are available?

Ductile iron, carbon steel, stainless steel, with various seat materials.

Do they require frequent maintenance?

No, gearboxes are typically sealed and require minimal maintenance.

Does Vcore Valve offer custom gear ratios?

Yes, gear ratios can be customised based on torque requirements.

References

-

AWWA C504 – Rubber-Seated Butterfly Valves

-

AWWA C516 – Large Diameter Valve Standards

-

ASME B16.34 – Valve Pressure and Temperature Ratings

-

ISO 5211 – Valve Actuation Interfaces

-

Valve Manufacturers Association (VMA)

-

Water Industry Mechanical Guidelines