Quick Overview

Exporting industrial valves to South America requires more than competitive pricing—it demands reliability, adaptability, and technical precision. In this customer case, Vcore Valve, based in Xiamen, China, successfully delivered manual knife gate valves to Brazil for use across multiple industrial sectors, proving strong performance under harsh working conditions.

Opening Scenario: A Practical Request from Brazil

“We need knife gate valves that can handle slurry, fibres, and frequent operation—delivery time is tight.”

This was the starting point when a Brazilian customer contacted Vcore Valve for a reliable solution suitable for mining and wastewater facilities.

Customer Pain Points

Severe Media Conditions

The system involved slurry, solids, and fibrous materials that often cause blockage.

Unstable Quality from Previous Suppliers

Earlier imported valves suffered from leakage and premature wear.

Tight Project Timeline

The valves had to be manufactured, tested, and shipped within a strict deadline.

Vcore Valve’s Solutions and Recommendations

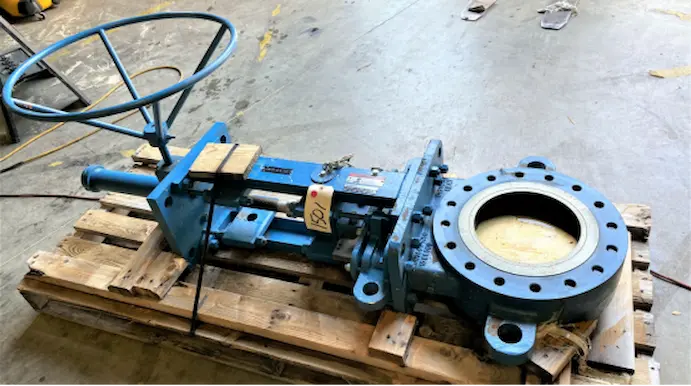

Optimised Knife Gate Valve Structure

A manual knife gate valve with a straight-through bore minimised clogging.

Material Selection for Durability

Materials were selected to resist abrasion and corrosion in aggressive media.

Comprehensive Quality Inspection

Each valve passed pressure, sealing, and operational tests before shipment.

Project Background and Valve Specifications

The valves were supplied for multiple Brazilian industrial facilities, including:

-

Mining slurry pipelines

-

Wastewater treatment plants

-

Industrial discharge systems

Main specifications:

-

Manual handwheel operation

-

Rising stem design

-

Replaceable resilient seat

-

DN80–DN300 sizes

-

Flanged end connections

Case Analysis: Why Manual Knife Gate Valves Were Selected

Compared with other valve types, manual knife gate valves offer superior performance in solid-laden media.

Key Advantages

-

Minimal pressure drop

-

Reliable shut-off

-

Simple maintenance structure

These benefits made them the most practical choice for the project.

Engineering Data and Performance Comparison

| Valve Type | Slurry Handling | Maintenance | Cost Efficiency |

|---|---|---|---|

| Butterfly Valve | Medium | High | Medium |

| Ball Valve | Low | Medium | Low |

| Knife Gate Valve | High | Low | High |

Field experience shows knife gate valves reduce blockage risk by over 40% in slurry systems.

Manufacturing and Quality Control in Xiamen

At Vcore Valve’s Xiamen facility, production followed a strict process:

-

Raw material inspection

-

Precision machining

-

Controlled assembly

-

Functional testing

-

Final export inspection

This ensured consistent quality across all delivered valves.

Logistics and Delivery to Brazil

The valves were packed in reinforced export cases, labelled clearly, and shipped by sea. Documentation complied with Brazilian import requirements, ensuring smooth customs clearance and on-time arrival.

Market Trends in South America

Brazil’s growing mining, wastewater, and industrial sectors are increasing demand for robust industrial knife gate valves. Buyers now prioritise:

-

Proven export experience

-

Stable manufacturing quality

-

Technical support

This project strengthened Vcore Valve’s long-term presence in South America.

Usage and Maintenance Recommendations

-

Operate knife gate valves fully open or closed

-

Avoid throttling applications

-

Inspect seats and packing periodically

-

Clean valves after extended slurry service

Proper maintenance can significantly extend valve service life.

Conclusion

This successful delivery confirms Vcore Valve’s capability as a reliable knife gate valve manufacturer in China. From engineering support to final delivery in Brazil, every step focused on performance, durability, and customer satisfaction.

👉 Contact Vcore Valve in Xiamen to discuss your manual knife gate valve requirements for global industrial projects.

FAQs

What are manual knife gate valves mainly used for?

They are ideal for slurry, solids, and fibrous media.

Are knife gate valves suitable for wastewater systems?

Yes, especially where clogging is a concern.

Can manual knife gate valves be automated later?

Yes, actuators can be added if required.

How long do knife gate valves typically last?

Usually 5–10 years depending on operating conditions.

Does Vcore Valve offer customised solutions?

Yes, sizes, materials, and standards can be customised.

Do you regularly export to Brazil?

Yes, Vcore Valve has strong export experience in South America.

Reference

-

Valve World Magazine – Knife Gate Valve Design Principles

-

ISO 9001 Quality Management Systems

-

Engineering Toolbox – Slurry Flow Control

-

Global Mining Review – Valve Selection in Mining

-

Water Environment Federation – Wastewater Valve Applications

-

International Journal of Industrial Valves – Knife Gate Valve Performance