Quick Summary

When it comes to controlling the flow of liquids, gases, or even solids in pipelines, ball valves stand out as one of the most reliable and versatile mechanical devices. A typical ball valve operates with a 90-degree handle rotation to open or close, aligning or blocking a ball-shaped disc’s hole with the flow path. This simple yet effective design makes ball valves a go-to choice for professionals and homeowners alike, offering quick shut-off, leak protection, and visual confirmation of status. Whether you’re working on an oil pipeline, a home plumbing system, or a chemical plant, choosing the right ball valve can prevent costly downtime and ensure long-term performance.

The Top 3 Pain Points With Ball Valves

Every plumber, engineer, or DIY enthusiast has faced frustration with ball valves at some point. Here are the most common issues and how to address them:

Leakage and Poor Seal Performance

A leaking ball valve can waste resources, damage equipment, and pose safety risks—especially with corrosive or high-pressure substances. This issue often stems from ill-fitting seats, worn-out elastomers, or incorrect installation.

Difficulty in Maintenance and Repair

Many ball valves (like one-piece designs) are hard to disassemble, making cleaning or part replacement a hassle. This leads to premature replacement instead of cost-effective repairs, increasing long-term expenses.

Incompatibility With System Requirements

Choosing a ball valve that’s too small, made from the wrong material, or unsuitable for pressure/flow needs results in restricted flow, pressure drops, or even valve failure. For example, using a low-pressure PVC ball valve in a high-velocity industrial system is a recipe for disaster.

3 Expert Solutions for Choosing the Perfect Ball Valve

To avoid the above pain points, follow these tailored solutions when selecting your ball valve:

Prioritize Seal Quality and Design

Opt for ball valves with high-quality elastomeric seats (for floating designs) or trunnion shafts (for true union models) to ensure a tight seal. Floating ball valves use seat compression to prevent leaks, while true union designs reduce friction and handle higher pressure—ideal for industrial applications. For extreme conditions, a welded body ball valve eliminates external leakage paths with non-destructive testing (NDT) certified welds.

Choose a Repairable, Easy-to-Maintain Design

Three-piece ball valves are a game-changer for maintenance. Their detachable body allows cleaning or part replacement without removing end caps from the pipeline, minimizing downtime. Avoid one-piece ball valves for systems requiring regular upkeep—reserve them for low-cost, low-maintenance applications like basic home plumbing.

Match Valve Specs to Your System

- Size and Port: Full-port ball-type valves have a hole equal to the pipe diameter, reducing friction and pressure drop—perfect for high-flow systems. Reduced-port (RB) valves are cost-effective for low-flow needs, but note the smaller ball opening.

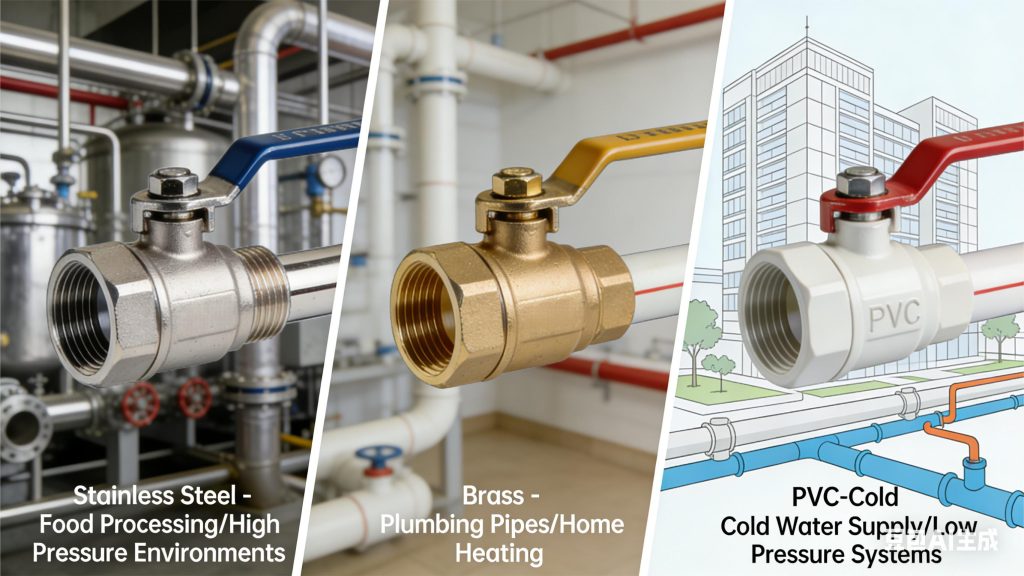

- Material: Stainless steel ball-type valves offer corrosion resistance for chemical or marine use. Brass/bronze valves work well in low/medium-pressure water systems. PVC valves are flexible and affordable for low-pressure applications.

- Operation: Manual ball-type valves(with handwheels/levers) are ideal for on-off control in small systems. For large industrial setups, consider electric or pneumatic actuated ball valves for automated operation.

Case Study

A mid-sized food processing plant struggled with redirecting fruit juice between two storage tanks while maintaining hygiene standards. Their existing two-port ball-type valves required manual switching, leading to downtime and cross-contamination risks.

The Solution

They upgraded to a 3-way stainless steel ball valve with a T-shaped ball design. This multi-port valve allowed seamless redirection of juice from one inlet to two outlets (or vice versa) without disassembling the pipeline. The stainless steel material ensured compliance with food safety regulations, and the easy-to-clean design reduced maintenance time.

The Result

- 40% reduction in downtime for flow redirection

- Zero cross-contamination incidents post-installation

- 25% lower maintenance costs due to durable, corrosion-resistant material

Source: Process Systems Industry Report 2023

Ball Valve Types: Data-Driven Comparison

Not all ball valves are created equal. Below is a detailed comparison of key types based on design, performance, and cost:

| Ball Valve Type | Design Highlights | Pressure Rating | Flow Efficiency | Maintenance | Cost Range (USD) | Best For |

| Floating Ball Valve | Elastomeric seats, 1/4-turn operation | Up to 1,000 psi | Medium | Low | 200 | Residential plumbing, low-pressure gas |

| True Union Ball Valve | Trunnion shafts, segmented ball | Up to 3,000 psi | High | Medium | 500 | Industrial high-pressure systems |

| One-Piece Ball Valve | Solid cast body, reduced bore | Up to 800 psi | Low | Very Low | 100 | Basic home use, non-critical systems |

| Two-Piece Ball Valve | Two-body construction, non-repairable when installed | Up to 1,500 psi | Medium-High | Low | 300 | Commercial plumbing, moderate pressure |

| Three-Piece Ball Valve | Detachable body, end caps remain on the pipe | Up to 2,500 psi | High | High | 600 | Industrial plants, frequent maintenance |

| V-Port Ball Valve | V-shaped ball/seat, linear flow control | Up to 2,000 psi | Very High | Medium | 800 | Throttling applications, high-velocity fluids |

| 3-Way Ball Valve | L/T-shaped ball, 3 ports | Up to 1,800 psi | Medium-High | Medium | 400 | Flow redirection, mixing applications |

Data compiled from industry standards (API 6D, ASME B16.34) and manufacturer specifications (DuraChoice, MIRAYA, Plumberstar)

Market Trends & Future of Ball Valves

The global ball valves market is projected to reach $21.3 billion by 2028, growing at a CAGR of 5.2% (Grand View Research). Key trends driving this growth include:

Industrial Automation: The demand for electric-and pneumatic-actuated ball-type valves is rising as industries adopt IoT and smart manufacturing. These valves offer remote control, real-time monitoring, and improved efficiency.

Sustainable Materials: Manufacturers are transitioning to eco-friendly materials, such as low-lead brass (per DIN 50930 T6) and recycled stainless steel, to meet environmental regulations (e.g., UBA list compliance).

High-Pressure Applications: With the expansion of oil and gas pipelines and renewable energy projects (e.g., hydrogen production), trunnion-mounted and welded body ball-type valves are in high demand for their ability to handle extreme pressure.

Miniaturization: Compact ball valves(like brass mini ball valves) are gaining popularity in medical devices, aerospace, and small-scale plumbing due to their space-saving design.

Style & Usage Tips for Ball Valves

Installation Best Practices

- Handle Alignment: Ensure the handle is parallel to the pipeline when open and perpendicular when closed for easy visual confirmation.

- Thread Sealing: Use Teflon tape or thread sealant for the threaded ball valve to prevent leaks—avoid over-tightening, which can damage threads.

- Welding Guidelines: For a welded body ball valve, use butt welding techniques and conduct NDT testing to ensure weld integrity.

Material Selection Cheat Sheet

| Application | Recommended Material |

| Home Plumbing (Water) | Brass/Bronze |

| Chemical Processing | Stainless Steel (314) |

| Low-Pressure Air/Gases | PVC |

| High-Pressure Oil/Gas | Welded Steel (Forged) |

| Food/Beverage Industry | Stainless Steel |

Maintenance Schedule

- Residential: Inspect ball valves annually for leaks; lubricate stems every 2–3 years.

- Commercial: Monthly visual checks; replace seats/elastomers every 1–2 years.

- Industrial: Weekly monitoring (via pressure gauges); full maintenance every 6 months.

Conclusion

Ball valves are the unsung heroes of fluid control—offering reliability, versatility, and ease of use across industries. By understanding your system’s pressure, flow, and material needs, you can select the perfect ball valve to avoid leaks, reduce downtime, and cut costs. Whether you’re a homeowner upgrading your plumbing or an engineer designing an industrial pipeline, the right ball valve makes all the difference.

Ready to find your ideal ball valve? Explore our range of industrial ball valves and residential ball valves for high-quality, compliant options. For custom solutions or expert advice, contact our team of ball valve specialists today—we’re here to help you make the right choice!

FAQ

Q1: What is the difference between a full-port and reduced-port ball valve?

A: A full-port ball valve has a ball hole equal to the pipe diameter, minimizing pressure drop and maximizing flow. A reduced-port (RB) valve has a smaller ball hole (e.g., a 3/4″ RB valve has a 1/2″ opening), which is more cost-effective but restricts flow.

Q2: Can ball valves be used for throttling?

A: Most ball valves are designed for on-off control, but V-port ball valves are specifically engineered for throttling. Their V-shaped ball/seat provides linear flow control, making them suitable for high-velocity fluids.

Q3: Are ball valves suitable for high-pressure applications?

A: Yes—true union (trunnion-mounted) and welded body ball valves are designed to handle high pressure (up to 3,000 psi). Avoid one-piece or PVC ball valves for high-pressure systems.

Q4: How do I know if a ball valve is open or closed?

A: Ball valves have a handle that is parallel to the pipeline when open and perpendicular when closed—this provides instant visual confirmation.

Q5: What material is best for corrosive environments?

A: Stainless steel ball valves are corrosion-resistant and ideal for chemical, marine, or industrial environments. Brass/bronze valves work for mild corrosion (e.g., water systems).

Q6: Can I repair a two-piece ball valve?

A: Two-piece ball valves are typically non-repairable when installed—you’ll need to remove them from the pipeline to access internal components. For repairability, choose three-piece ball valves.

Q7: How long do ball valves last?

A: With proper installation and maintenance, ball valves can last 10–20 years. Stainless steel and brass valves have longer lifespans than PVC, especially in harsh conditions.