Quick Summary

Knowing the exact ball valve position sounds basic, yet it remains one of the most common causes of operational errors in industrial systems. From unexpected pressure drops to complete line shutdowns, misjudging whether a valve is open or closed can be costly. At Vcore Valve, we regularly encounter this issue across oil & gas, chemical, and general industrial projects. This guide explains how to properly determine ball valve open and closed positions, using clear rules, real examples, and engineering logic you can trust.

A Real-World Site Scenario

“The handle looks straight—so it must be open, right?”

Ten minutes later, the pump trips.

Ball valves are often considered “fool-proof”, yet incorrect assumptions about ball valve handle position remain surprisingly common—especially during commissioning, maintenance, or emergency operations.

Common User Pain Points

Unclear Handle Orientation

In tight installations, handles may be rotated, shortened, or repositioned, making ball valve open closed position unclear.

No Visual Indicator

Some industrial ball valves lack a clear stem slot or position indicator, leaving operators to guess.

Mismatch Between Flow Direction and Handle

Operators often confuse ball valve flow direction with handle alignment, especially in complex piping layouts.

Practical Solutions from Vcore Valve

Follow the Handle-to-Pipe Rule

For standard manual valves:

-

Handle parallel to pipeline → valve open

-

Handle perpendicular to pipeline → valve closed

This rule applies to most industrial ball valves, regardless of size.

Check the Stem Slot or Indicator

On many valves, the stem top slot aligns with the ball bore:

-

Slot parallel to flow → open

-

Slot across flow → closed

Confirm with Valve Design Information

Always review the valve datasheet, especially for trunnion mounted ball valves or automated units.

Case Studies from Industrial Applications

Case 1: Chemical Plant Maintenance Shutdown

A maintenance team assumed a valve was closed based on handle position alone. The valve had been reassembled with the handle offset by 90°.

Lesson: Handle position alone is not enough—verify the stem indicator.

Case 2: Pipeline Commissioning Project

A pipeline ball valve with a gearbox included a clear position indicator window.

Result: Zero misoperation incidents during commissioning.

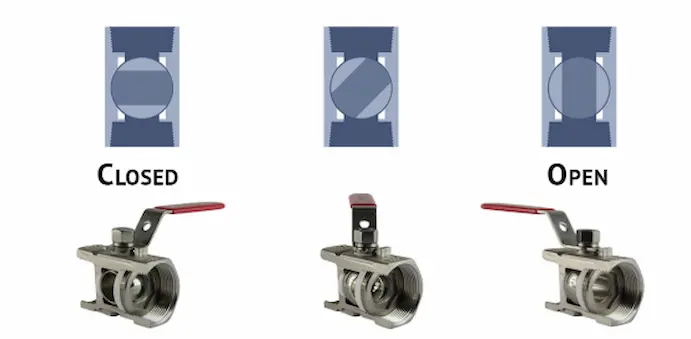

Technical Logic Behind Ball Valve Position

A ball valve works by rotating a bored sphere:

-

Open: Bore aligns with flow path

-

Closed: Solid side blocks flow

Understanding this simple geometry makes identifying ball valve open closed position intuitive—even when external indicators are unclear.

Comparison: Manual vs Gear-Operated Valves

| Valve Type | Position Identification |

|---|---|

| Manual lever ball valve | Handle alignment |

| Gear-operated ball valve | Indicator plate |

| Actuated ball valve | Limit switches / position feedback |

Data, Safety, and Operational Impact

According to industry maintenance reports, incorrect valve positioning contributes to:

-

~30% of unexpected flow restrictions

-

Increased wear on pumps and seals

-

Higher safety risks during isolation

Clear valve position indication directly improves plant reliability and operator safety.

Market Trends and Industry Insight

-

Increasing use of visual position indicators on industrial valves

-

Growing demand for ISO 5211 mounting with clear open/close feedback

-

Automation driving the need for precise ball valve position monitoring

At Vcore Valve, we now integrate clear mechanical indicators as standard on many valve designs.

Best Practice Tips from Vcore Valve

-

Never rely on handle position alone in critical systems

-

Mark open/closed directions clearly during installation

-

Use lockable handles for safety isolation

-

Train operators using actual valve cutaway visuals

Conclusion

Correctly identifying the position of a ball valve is essential for safe, efficient operation. Simple rules—combined with proper indicators and training—can eliminate costly mistakes.

If you need industrial ball valves with clear, reliable position indication, Vcore Valve is ready to support your project with engineering-driven solutions.

👉 Contact Vcore Valve today for technical advice or customised valve designs.

FAQs

How do I know if a ball valve is open or closed?

Check whether the handle or stem indicator is parallel (open) or perpendicular (closed) to the pipeline.

Does flow direction affect ball valve position?

No. Ball valve flow direction is independent of open/closed position.

Are all ball valves quarter-turn?

Yes. Standard ball valves operate with a 90-degree rotation.

What about automated ball valves?

They rely on limit switches or position feedback systems rather than visual handles.

Can handle position be misleading?

Yes, especially after maintenance or reassembly.

Does Vcore Valve provide position indicators?

Yes. Many Vcore Valve industrial ball valves include clear mechanical indicators as standard.

References

-

Valve Manufacturers Association (VMA) – Valve Operation and Safety Guidelines

-

API 6D – Specification for Pipeline Valves

-

ASME B16.34 – Valves: Pressure–Temperature Ratings

-

ISO 5211 – Actuator Mounting Standards

-

Engineering Toolbox – Valve Symbols and Operation Principles

-

OSHA – Lockout/Tagout Safety Practices

-

Vcore Valve Technical Library – Ball Valve Operation Guide