The Control Room Conversation That Matters

Plant Manager: “Our turbine cycle efficiency has dropped by nearly 2%. We suspect valve-related losses, but a full shutdown isn’t an option. What can we do?”

Vcore Specialist: “This is exactly where precision valve engineering proves its value. From main steam isolation to feedwater regulation, the right valve selection can recover those 2% losses—while increasing safety. Let me share how we’ve achieved this for other facilities.”

At Vcore Valve, we know that every fraction of efficiency in a power plant translates directly into lower fuel costs, fewer unplanned outages, and higher operational reliability.

⚡ Key Valve Applications in Power Generation

Main Steam Systems

- Isolation Valves:Provide rapid shutoff during emergency events

- Control Valves:Regulate steam flow to turbines with high accuracy

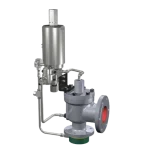

- Safety Valves:Protect boilers and piping from overpressure

Vcore Solution: Our HP-900 Series Gate Valves, built from high-temperature steels with stellite sealing, maintain tight shutoff even after more than 10,000 cycles at 540°C superheated steam.

Feedwater Systems

- Check Valves:Block reverse flow and protect feed pumps

- Control Valves:Stabilize drum levels to protect turbine integrity

- Isolation Valves:Enable safe maintenance without full system shutdown

Cooling Water Circuits

- Butterfly Valves:Cost-effective, lightweight control for large-diameter pipes

- Ball Valves:Reliable tight shutoff for exchangers and condensers

📊 Valve Performance Impact Matrix

| System | Efficiency Impact | Reliability Factor | Vcore Recommended Solution |

| Main Steam | 3–5% cycle gain | Critical for availability | HP-900 Gate Valves |

| Feedwater | 1–2% heat rate boost | Prevents turbine damage | FC-700 Control Valves |

| Condensate | 0.5–1% improvement | Reduces pump cavitation | DBB Ball Valve Systems |

| Cooling Water | 2–3% output variation | Maintains condenser vacuum | Aqua-Seal Butterfly Valves |

Case Study: 650MW Coal-Fired Plant, Southeast Asia

Challenges:

- Severe trim erosion in steam control valves

- Annual maintenance costs exceeding $200,000

Vcore Intervention:

- Material Upgrade:Cobalt-based alloys for erosion resistance

- Design Optimization:Cavitation-reducing flow geometry

- Smart Maintenance:Digital positioners with real-time monitoring

Results (12 Months):

- ✔️ 2.8% overall efficiency improvement

- ✔️ 67% fewer valve-related maintenance hours

- ✔️ Zero unplanned outages

- ✔️ ROI recovered in just 8 months

🌡️ Performance Under Extreme Conditions

- Supercritical Steam:Withstand 620°C and 250+ bar, thanks to advanced heat treatment and weld integrity procedures

- Nuclear Safety:ASME III certified valves with complete material traceability and rapid-response safety relief designs

- Renewables:Specialized alloys and coatings for geothermal, biomass, and hydroelectric environments

💡 Technologies That Drive Efficiency

- Smart Valve Systems:Digital positioners with 15% accuracy, predictive monitoring, and vibration analysis

- Advanced Materials:High-temperature alloys, anti-erosion coatings, and lightweight composites

- Maintenance Optimization:Condition-based service intervals, extending valve lifecycles by up to 300%

Performance Benchmarks

- Operational Availability:>99.5%

- Emergency Response:<2 seconds

- Leakage Rate:<0.01% of rated flow

- Service Life:20–25 years with proper upkeep

🔍 Specialized Applications

- Combined Cycle Plants:Valves engineered for rapid cycling and thermal shock resistance

- Hydroelectric:Large-diameter butterfly valves for penstock control

- Biomass:Abrasion-resistant valves designed for particulate-laden flow

- Geothermal:Corrosion-resistant alloys for aggressive fluids

FAQ

Q: How often should power plant valves be tested?

A: Safety valves: quarterly. Isolation valves: monthly. Control valves: during scheduled outages.

Q: What’s the average lifespan of main steam valves?

A: 20–25 years with proper service. Trim may need refurbishment every 5–8 years.

Q: Can older valves be upgraded?

A: Yes. Retrofit kits (new trim, actuators, controls) improve performance by 15–30% without full replacement.

Q: How do you respond to urgent repair needs?

A: Vcore maintains critical spare inventory and provides 24/7 emergency technical support