Quick Overview

A CF8M ball valve is a stainless steel ball valve manufactured from ASTM A351 CF8M material, widely recognised for its excellent corrosion resistance, mechanical strength, and suitability for demanding industrial environments. At Vcore Valve, CF8M ball valves are frequently specified for chemical processing, marine systems, oil & gas, and food-grade applications where durability and reliability are non-negotiable.

Opening Scenario: A Typical Engineering Discussion

“Is CF8 good enough, or do we really need CF8M?”

“It’s only a bit more expensive—does it really matter?”

This question comes up repeatedly during project reviews. In reality, choosing between CF8 and CF8M can determine whether a valve lasts five years—or fifteen.

User Pain Points

Confusion Around Stainless Steel Grades

Many buyers assume all stainless steel ball valves perform the same, underestimating the role of molybdenum in CF8M.

Premature Corrosion Failures

Using standard stainless steel in chloride-rich or mildly acidic environments often leads to pitting corrosion.

Over-Specification or Under-Specification

Either overspending on unnecessary alloys—or worse, selecting a valve that fails compliance audits.

Solutions & Expert Recommendations

Choose Material Based on Media, Not Price

CF8M offers superior resistance to chlorides, acids, and saline environments compared with CF8.

Verify ASTM and EN Compliance

Always confirm ASTM A351 CF8M casting standards and pressure test requirements.

Work With Application-Driven Manufacturers

At Vcore Valve, material selection is tied directly to service conditions, not catalogue shortcuts.

What Is CF8M Material?

CF8M is an austenitic stainless steel casting grade equivalent to AISI 316 stainless steel.

Its defining feature is the addition of 2–3% molybdenum, which significantly improves corrosion resistance.

Typical Chemical Composition of CF8M

-

Chromium: 18–21%

-

Nickel: 9–12%

-

Molybdenum: 2–3%

-

Carbon: ≤0.08%

This composition makes CF8M ideal for aggressive industrial fluids.

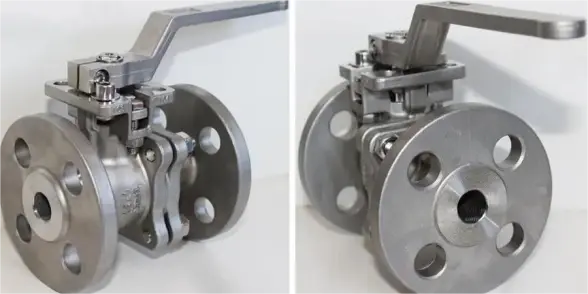

Types of CF8M Ball Valves

CF8M Floating Ball Valve

Suitable for low to medium pressure systems, offering tight shut-off and simple construction.

CF8M Trunnion Mounted Ball Valve

Designed for high-pressure pipelines, reducing operating torque and seat wear.

CF8M Full Bore Ball Valve

Minimises pressure drop and allows pigging in pipeline systems.

CF8M V-Port Ball Valve

Provides throttling capability while maintaining corrosion resistance.

CF8M vs CF8: Technical Comparison

| Property | CF8 | CF8M |

|---|---|---|

| Base Equivalent | 304 SS | 316 SS |

| Molybdenum | No | Yes |

| Corrosion Resistance | Good | Excellent |

| Chloride Resistance | Moderate | High |

| Typical Applications | Water, air | Chemicals, marine |

Case Studies from Vcore Valve

Case 1 – Chemical Transfer Line

A client replaced CF8 valves with CF8M ball valves in a mild acid service. Result: valve lifespan increased by over 70%.

Case 2 – Offshore Utility System

CF8M ball valves eliminated pitting corrosion failures caused by salt-laden air exposure.

Data & Engineering Considerations

-

CF8M performs significantly better in chloride environments above 200 ppm

-

Suitable for operating temperatures up to approximately 425°C

-

Compatible with PTFE, RPTFE, and metal seats

Market Trends & Industry Insights

-

Rising demand for CF8M valves in offshore and desalination projects

-

Increasing preference for stainless steel valves over carbon steel in lifecycle-cost analysis

-

Stricter corrosion compliance in EU and Middle East markets

Usage & Selection Tips

-

Use CF8M ball valves for corrosive or saline media

-

Avoid CF8 in coastal or chemical environments

-

Confirm pressure class and seat material compatibility

-

Always request material test certificates (MTC)

Conclusion

A CF8M ball valve is not just a stainless steel upgrade—it is a strategic material choice that directly impacts system reliability and maintenance cost. At Vcore Valve, we manufacture CF8M ball valves to meet real industrial demands, ensuring long-term performance in the harshest environments.

FAQ – CF8M Ball Valves

Q1: What does CF8M mean in ball valves?

CF8M refers to an ASTM stainless steel casting grade equivalent to 316 stainless steel, containing molybdenum for enhanced corrosion resistance.

Q2: Is CF8M better than CF8?

Yes. CF8M offers superior resistance to chlorides, acids, and pitting corrosion.

Q3: Where are CF8M ball valves commonly used?

They are widely used in chemical processing, marine systems, oil & gas, and food industries.

Q4: Can CF8M ball valves handle high temperatures?

Yes, they typically perform reliably up to around 425°C, depending on design and seat material.

Q5: Are CF8M ball valves food-safe?

Yes, when manufactured and finished to appropriate hygienic standards.