Quick Summary

Gate valves play a key role in isolating pipelines in water, oil, gas, and industrial processing systems. Their shut-off reliability depends on the wedge type, stem design, sealing materials, and pressure class. Many performance issues—such as internal leakage or incomplete closure—are usually caused by incorrect specification rather than manufacturing defects.

This guide provides a technically focused overview of wedge gate valve structure, working principle, types, materials, and selection tips, helping engineers and purchasers specify the correct configuration for long-term service.

Why careful selection matters

An incorrect valve choice can cause leaks, frequent maintenance, or even safety incidents. Selection revolves around five primary factors: fluid characteristics, pressure and temperature, frequency of operation, allowable leakage, and maintenance access. In corrosive or high-temperature services, material selection is equally important; ductile iron can be economical for potable water, while cast steel helps with higher pressures and stainless grades suit corrosive chemicals.

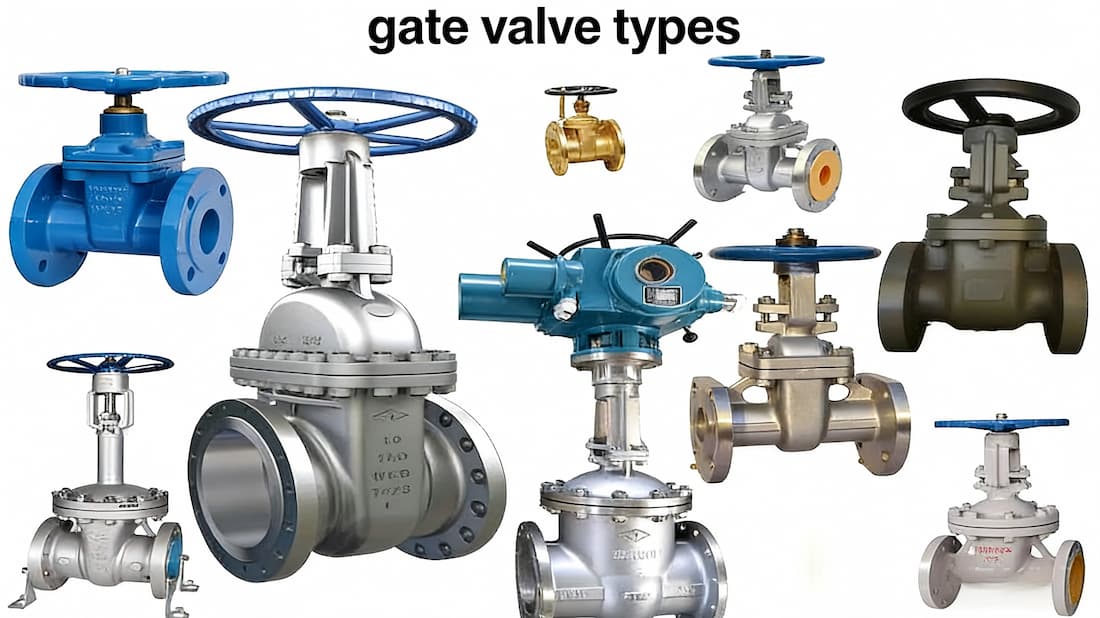

The five gate valve types

Wedge gate valve

The wedge gate valve uses a tapered wedge that seats into match-machined seat faces. It is a robust, time-tested option for many industries and is often specified where a tight shut-off and mechanical strength are required. Solid wedge designs are favoured where thermal cycling is limited; flexible or split wedges accommodate minor misalignment and thermal expansion.

Typical uses: general isolation in oil & gas, water works, and process plants.

Parallel slide gate valve

Parallel slide designs use two flat gate faces guided into seat rings. Springs or mechanical actuators push the seats toward the gate for a tight seal. These valves excel where thermal expansion or seat wear might otherwise cause jamming.

Typical uses: steam systems and high-pressure pipelines where re-seating is needed after wear.

Resilient seated gate valve

Here, an elastomeric seat is either bonded or mechanically retained in the body or seat ring. The soft seat provides excellent sealing for potable water distribution and fire systems; expect near-zero leakage results when correctly specified.

Typical uses: municipal water, wastewater, and applications requiring leak-free isolation.

Metal seated gate valve

Metal-to-metal seats, often hardened or coated, are necessary when temperature and abrasive particles would quickly degrade elastomer seats. These valves tolerate greater thermal stress and abrasive media at the expense of allowing a very small, controlled leakage in some designs.

Typical uses: petrochemical, steam headers, slurries.

OS&Y and non-rising stem valves

-

OS&Y (Outside Screw & Yoke) valves show the stem travel externally; the rising stem indicates valve position and simplifies visual inspection.

-

Non-rising stem valves maintain stem position while the handwheel turns; these are compact and ideal where vertical space is limited or where valves will be buried.

Both styles can be built with resilient or metal seats and in a range of body materials to match service needs.

Gate valve parts — what to inspect and why

Knowing the components helps with selection and troubleshooting:

-

Body: Pressure-containing shell; choose a material compatible with pressure and media (ductile iron, cast steel, stainless steel).

-

Bonnet: Provides access to internals; bonnet design and bolting pattern affect maintainability.

-

Gate/Wedge: The component that blocks flow; may be solid, flexible, or parallel.

-

Seat rings: Often replaceable; exist as resilient inserts or metal seats.

-

Stem: Transfers motion; choice of rising or non-rising stem affects feedback and space.

-

Packing and gland: Stem sealing assembly; packing material should suit temperature and chemical exposure.

-

Actuation or gearbox: Manual handwheel, gearbox or motorised actuator as required by torque and duty cycle.

-

Bonnet bolting and gaskets: Ensure torque and gasket class match flange and temperature service.

A proactive inspection checklist focusing on wear at seats, stem straightness, packing condition and bonnet bolts prevents costly failures.

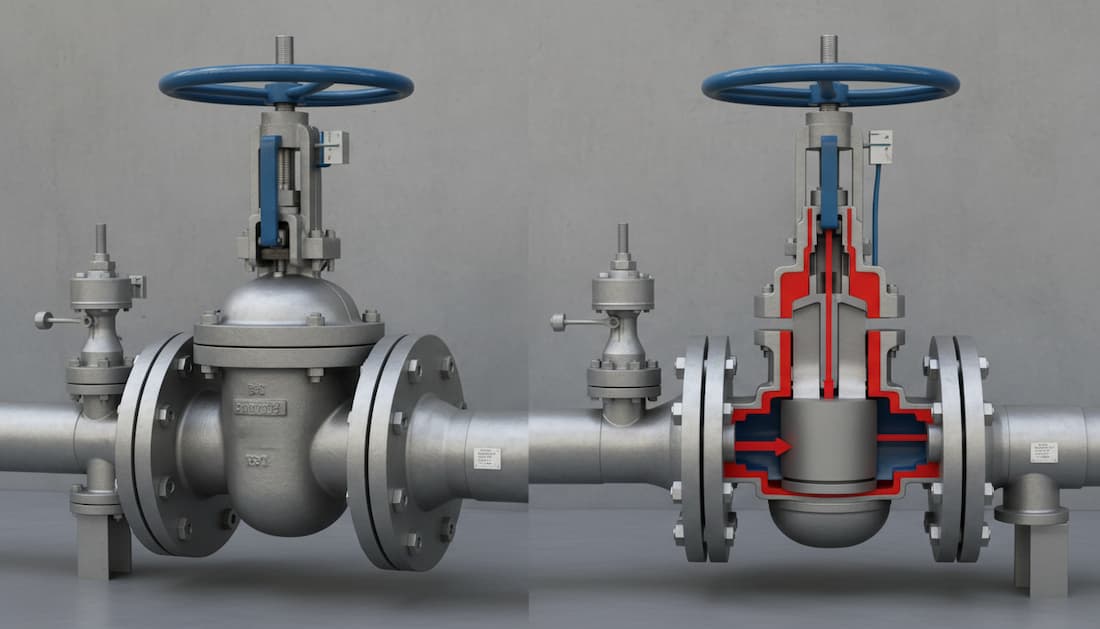

How does a gate valve work?

A gate valve opens and closes by moving the gate perpendicularly to the flow path. Typical operation steps:

Opening: Rotation of the handwheel or actuator raises the stem and gate, clearing the flow path to produce a full bore with minimal pressure loss.

Closing: Lowering the gate allows it to seat in the ring, compressing a resilient insert or bringing metal faces into contact to create isolation.

Seating mechanics: In resilient designs, the seat compresses to seal; in metal-seated valves, precise machining and surface treatments produce a metal-to-metal interface that resists high temperatures and erosion.

Not for throttling: Partial openings cause turbulent flow and can damage both gate and seat; select a control valve for modulating service.

Torque and maintenance: Metal seating requires higher seating torque for positive closure; verify actuator sizing and torque limits during procurement.

Understanding this linear action is essential when defining maintenance cycles and evaluating failure modes.

Material selection: ductile iron, cast steel, stainless steel

Material choice should be guided by the fluid chemistry, operating temperature and pressure and corrosion allowances.

-

Ductile iron gate valve: Economical, strong and commonly epoxy-coated for potable water service. It suits low-to-moderate temperature systems and is widely used for municipal pipelines.

-

Cast steel gate valve (WCB): Designed for higher temperatures and pressures; typical in oil, gas and steam lines where mechanical toughness is required.

-

Stainless steel gate valve (CF8M/CF3M): Selected for corrosive or hygienic services—chemical plants, seawater lines or food-grade systems—where corrosion resistance is paramount.

Specification notes: verify material traceability, heat treatment and any required lining or coating for long-term performance.

Practical selection guide — step-by-step

Define service conditions: fluid, solids content, pressure, temperature, and frequency of operation.

Select seat type: resilient for clean water and leak-free shut-off; metal for abrasive, high-temperature services.

Choose valve type: wedge for conventional isolation, parallel for thermal cycling, resilient seated for zero-leak applications.

Pick material: ductile iron for water; cast steel for high pressure and temperature; stainless steel for corrosive media.

Decide actuation: manual handwheel for small valves; gearbox or motor/pneumatic actuators for larger sizes or automated systems.

Specify standards: API 600, AWWA C515, ISO or EN equivalents, depending on project jurisdiction.

Following this decision tree reduces rework and ensures compatibility with existing pipeline standards.

Troubleshooting & maintenance tips

-

Seat leakage: Check for seat damage, foreign objects or improper seating torque. Replace seat rings if scored or deformed.

-

Valve seizure: Exercise valves periodically; flushed pipelines reduce debris accumulation; apply proper lubrication where permitted.

-

Packing leaks: Replace packing with a material specified for the service (e.g., graphite for high temperature). Ensure correct gland torque.

-

Actuator issues: Periodically verify torque settings and travel limits; check electrical and pneumatic connections.

A written maintenance plan with intervals for exercising, inspection and spare parts inventory (seat rings, gate, stem, packing) is best practice.

Technical comparisons

Typical pressure drop

-

Gate valve (wide open): very low

-

Globe valve: moderate to high

-

Butterfly valve: moderate

Seating characteristics

| Seat type | Suitable for | Key advantage |

|---|---|---|

| Resilient seated | Waterworks, fire service | Tight shut-off |

| Metal seated | Steam, petrochemical | High temp & abrasion resistance |

Industry trends & insights

-

Leakage control: Utilities increasingly prefer resilient-seat designs to minimise non-revenue water losses.

-

Material demand: Chemical and desalination projects boost demand for stainless steel valves.

-

Automation: More isolation valves are fitted with position sensors and remote actuation for predictive maintenance.

-

Standards & traceability: Clients increasingly demand certified materials and traceable documentation to meet compliance and warranty needs.

-

GATE VALVE

Style & usage recommendations

-

Do not use gate valves for throttling. Use globe or dedicated control valves for flow regulation.

-

Use OS&Y construction where a visible indication of valve status is required, particularly in safety-critical applications.

-

Specify non-rising stems for buried or space-limited installations; provide extension stems for below-ground installations.

-

Keep spare seat rings, stems and packing on-site where critical valves exist to shorten downtime.

Conclusion & call to action

Choosing the correct valve type, seat construction and material saves maintenance time, reduces lifecycle cost and improves safety. For assistance selecting flanged gate valves in ductile iron, cast steel or stainless steel, contact our engineering team for a tailored recommendation and prompt quotation.

Contact Vacore Valve for specification support.

FAQ

-

What is the main purpose of a gate valve?

A gate valve is intended for full isolation, providing minimal flow resistance when open. -

What are the principal parts of a gate valve?

Body, bonnet, gate/wedge, seat rings, stem, packing, handwheel or actuator and bolting/gaskets. -

How does a gate valve work?

By linear motion: raising the gate to open and lowering it to close, producing a clear flow path or a seal. -

Can gate valves be used for throttling?

No. Partial opening risks seat and gate damage and is not recommended. -

When should I specify a metal-seated design?

Specify metal seats for high-temperature, abrasive or erosive services. -

Which materials are best for corrosive media?

Stainless steel grades are typically used where corrosion resistance is essential. -

What is an OS&Y valve used for?

It is used where visible confirmation of valve position is required, especially in safety or firefighting systems.

References

-

ASME B16.34 – Valves: Flanged, Threaded and Welding End.

-

AWWA C515 – Resilient-Seated Gate Valves for Water Supply Service.

-

API 600 – Steel Gate Valves—Flanged and Butt-Welding Ends.

-

ISO 5208 – Industrial Valves — Pressure Testing.

-

Valve Manufacturers Association — Technical resources.