Quick Overview

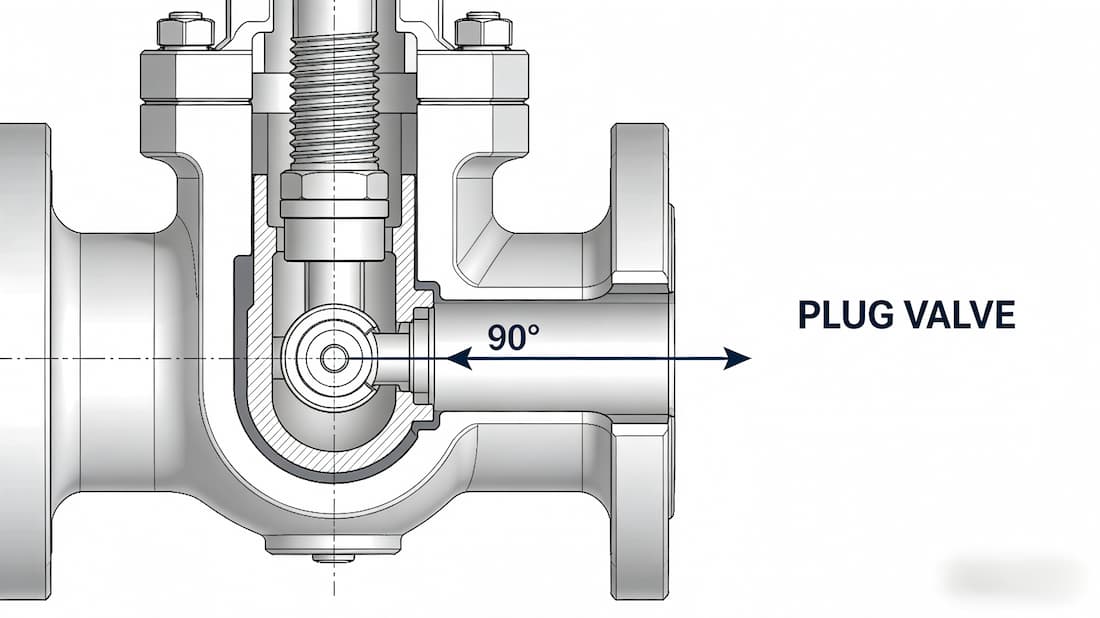

A custom plug valve is a precision-engineered flow control device that uses a rotating cylindrical or conical plug to start or stop fluid movement. This guide explains the five key types, essential materials for industrial applications, and how stainless steel plug valves improve durability and performance in demanding systems.

⭐ Opening Scenario

Imagine a chemical plant where the service medium is a corrosive solvent at 180°C. A standard valve starts leaking after six months. Production halts. Losses rise. The engineer knows the problem isn’t the process—it’s choosing the wrong valve design. This guide helps prevent that by showing exactly which plug valve configuration works best in industrial settings.

⭐ User Pain Points

Pain Point 1 — Standard plug valves fail in harsh media

Many general-purpose valves cannot withstand solvents, acids, and high temperatures.

Pain Point 2 — Wrong type selection causes leakage and downtime

Users often don’t know the difference between lubricated, non-lubricated, and eccentric plug valves.

Pain Point 3 — Limited customisation slows engineering projects

Industrial buyers struggle to source custom plug valve configurations that match the exact pressure class, material, or flange standards.

⭐ Practical Solutions / Recommendations

Solution 1 — Select stainless steel plug valves for corrosion resistance

A stainless steel plug valve offers superior durability against corrosive media, making it ideal for chemical, petrochemical, and offshore applications.

Solution 2 — Choose the correct plug valve type based on sealing performance

For tight shut-off → eccentric plug valve

For heavy-duty oil service → lubricated plug valve

For clean, hygienic systems → Non-lubricated designs

Solution 3 — Use fully custom plug valve engineering

Customization ensures correct pressure ratings, port design, actuator mounting, and flange standards, reducing installation risks.

⭐ Case Studies

Case 1 — High-temperature solvent transfer line

A refinery replaced bronze valves with custom stainless steel plug valves (PN25).

Result:

-

Zero leakage within 18 months

-

50% lower maintenance cost

-

Improved process stability

Case 2 — Municipal wastewater treatment upgrade

Engineers used eccentric plug valves to handle solids and slurry.

Result:

-

35% reduction in clogging

-

5-year uninterrupted service

⭐ Scientific Data & Technical Comparison

| Feature | Plug Valve | Ball Valve | Gate Valve |

|---|---|---|---|

| Best For | Dirty/viscous / corrosive media | General isolation | Clean fluids |

| Sealing | Metal or PTFE-seated | PTFE-seated | Metal-seated |

| Operation | 90° rotation | 90° rotation | Multi-turn |

| Maintenance | Low / Medium | Low | Medium |

| Pressure Suitability | Excellent in high-pressure systems | Good | Good |

Key Insight:

A custom plug valve provides more stable sealing under variable pressure compared with gate valves and is less sensitive to suspended solids than ball valves.

⭐ Industry Trends & Market Insights

-

Shift toward stainless steel plug valves due to global environmental regulations and corrosive media handling.

-

Increasing use of automation-compatible plug valves with ISO 5211 direct mounting pads.

-

Eccentric plug valves are rapidly replacing butterfly valves in sludge and slurry applications.

-

Customization demand rises for API 598 / API 6D compliant designs.

⭐ Style & Usage Recommendations

-

Use Vacore Valve‘s lubricated plug valves in oil, fuel, or viscous hydrocarbon pipelines.

-

Select corrosion-resistant plug valve materials (SS316 / Duplex) for chemical and marine applications.

-

Use flanged plug valves for stable installation in high-pressure networks.

-

Verify plug valve working principle for your system—especially port shape (round, rectangular) and opening torque.

⭐Conclusion & CTA

A custom plug valve offers unmatched flexibility for corrosive, high-pressure, or abrasive media. With the correct type, material, and design, you gain longer service life, reduced maintenance, and safer operations.

👉 Ready to source high-performance custom plug valves?

Contact Vcore Valve for engineering support and customized industrial valve solutions.

✅ FAQ

Q 1 — What is a custom plug valve?

A custom plug valve is a plug valve engineered to specific requirements such as bore design, material grade, port geometry, pressure class, or coating. It provides improved sealing, corrosion resistance, and lifespan compared with standard catalogue models, especially in demanding industrial applications.

Q 2 — When should I use a stainless steel plug valve instead of cast iron or carbon steel?

Choose stainless steel plug valves when handling corrosive media, high temperatures, or hygienic applications. They are ideal for chemical plants, offshore platforms, water treatment, and general industrial fluid control, where corrosion resistance and cleanability are essential.

Q 3 — What are the main types of plug valves?

The most common plug valve types include:

• Lubricated plug valve

• Non-lubricated plug valve

• Eccentric plug valve

• Expanding plug valve

• Multi-port plug valve

Each has unique advantages depending on pressure, sealing, and media requirements.

Q 4 — Are plug valves suitable for high-pressure systems?

Yes—high-pressure plug valves (Class 600–2500) are widely used in oil & gas and chemical pipelines. Stainless steel or alloy construction with metal-to-metal seating is recommended for extreme pressure and temperature conditions.

Q 5 — Can plug valves handle abrasive or dirty media?

Eccentric plug valves are the best option for slurry, sludge, or fluids containing suspended solids. Their design prevents jamming and significantly reduces wear, making them popular in wastewater and mining operations.

Q 6 — How long does a custom plug valve typically last?

With proper material selection and periodic maintenance, industrial plug valves can operate reliably for 10–20+ years. Stainless steel valves typically offer the longest lifespan in corrosive and high-duty environments.

✅ References

• “Plug Valves – Design & Applications Explained.”

• “Valve Material Selection Guide” — Materials Today

• “Industrial Valve Standards & Specifications” — ASTM International