🔍 Quick Overview

Sump pump check valves play a critical role in preventing backflow, protecting pumps, and improving drainage efficiency. Without a properly selected check valve, sump systems suffer from short cycling, water hammer, and premature pump failure. In this guide, Vcore Valve explains the main types of sump pump check valves, how they work, where they are best applied, and how to choose the right one for residential and commercial drainage systems.

🎬 Opening Scenario: A Familiar Basement Problem

“Why does my sump pump keep restarting every few seconds?”

“Why does water fall back into the pit after the pump shuts off?”

In most cases, the issue is not the pump — it’s the check valve. Choosing the wrong sump pump check valve (or skipping one entirely) leads to wasted energy, noise, and system failure.

⚠️ User Pain Points

1. Backflow After Pump Shutdown

Without an effective sump pump check valve, discharged water flows back into the pit, forcing the pump to restart repeatedly.

2. Water Hammer & Noise

Fast-closing or poorly designed valves cause pipe shock, vibration, and loud banging sounds.

3. Premature Pump Wear

Short cycling dramatically reduces pump lifespan and increases maintenance costs.

✅ Solutions & Expert Recommendations

1. Install the Correct Check Valve Type

Different sump systems require different valve designs — not all check valves perform equally.

2. Match Valve Material to Environment

PVC, rubber, and metal check valves behave differently under pressure, debris, and temperature changes.

3. Prioritise Flow Control & Reliability

At Vcore Valve, sump check valves are tested for sealing reliability, low head loss, and durability.

🔧 What Is a Sump Pump Check Valve?

A sump pump check valve is a one-way valve installed on the pump discharge line. It allows water to flow out but automatically closes when the pump stops, preventing reverse flow.

Core functions include:

-

Preventing backflow

-

Reducing pump cycling

-

Minimising pipe shock

-

Improving system efficiency

🔩 Main Types of Sump Pump Check Valves

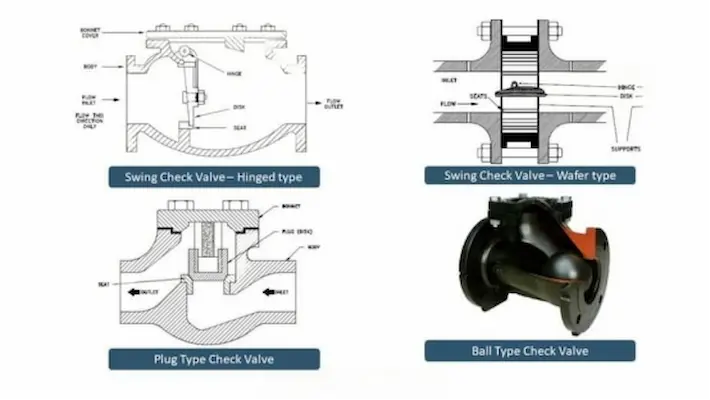

1. Swing Check Valve

Uses a hinged flap that opens with forward flow.

Best for low-pressure systems with minimal debris.

2. Spring-Loaded (Silent) Check Valve

Closes smoothly using a spring mechanism.

Excellent for noise reduction and vertical installations.

3. Flapper Check Valve

Rubber flapper design with flexible sealing.

Popular in residential sump systems.

4. Ball Check Valve

Uses a floating ball to block reverse flow.

Suitable for slurry or debris-laden water.

Data & Technical Comparison

| Valve Type | Backflow Control | Noise Level | Maintenance | Typical Use |

|---|---|---|---|---|

| Swing Check Valve | Moderate | Medium | Low | Residential |

| Spring Check Valve | Excellent | Very Low | Medium | Commercial |

| Flapper Valve | Good | Low | Low | Home basements |

| Ball Check Valve | Excellent | Medium | Medium | Dirty water |

🧪 Case Studies from Vcore Valve

Case 1 – Residential Basement Drainage

Replacing a swing valve with a spring-loaded check valve reduced pump cycling by 45% and eliminated pipe noise.

Case 2 – Commercial Sump System

Ball check valves prevented clogging caused by sediment, extending pump service life by over 18 months.

📈 Market Trends & Industry Insights

-

Growing demand for silent sump pump check valves

-

Increased use of PVC and elastomer-sealed designs

-

Preference for low-head-loss check valves in energy-efficient buildings

🛠 Usage & Selection Tips

-

Install vertically where possible

-

Avoid undersized valves

-

Ensure easy access for inspection

-

Select corrosion-resistant materials

-

Always verify pressure and flow ratings

✅ Conclusion

Sump pump check valves may look simple, but their impact on system reliability is enormous. Choosing the right valve prevents backflow, protects your pump, and saves long-term costs. At Vcore Valve, we engineer check valves that deliver quiet operation, reliable sealing, and extended service life.

👉 Contact Vcore Valve for technical support, drawings, or customised sump pump check valve solutions.

❓ FAQ – Sump Pump Check Valves

Q1: Do all sump pumps need a check valve?

Yes. A check valve prevents discharged water from flowing back into the sump pit, reducing pump cycling.

Q2: Where should a sump pump check valve be installed?

Typically on the discharge pipe, just above the pump or slightly above the pit.

Q3: What is the quietest sump pump check valve?

Spring-loaded (silent) check valves offer the lowest noise and smooth closure.

Q4: How often should a check valve be replaced?

Most valves last 3–5 years depending on water quality and usage.

Q5: Can a check valve fail?

Yes. Debris, wear, or improper installation can cause leakage or sticking.