Quick Summary

Comparing rising stem vs non-rising stem gate valves is more than a visual preference—it directly affects installation space, maintenance strategy, safety, and long-term reliability. At Vcore Valve, we regularly see valve performance issues caused by incorrect stem selection. This guide explains the structural differences, operating principles, real-world applications, and selection criteria to help engineers and buyers make confident decisions.

Opening Scenario: A Familiar Engineering Debate

“Can we see if the valve is open?”

That simple question comes up time and again on construction sites and in pump rooms. One engineer points at a clearly visible rising stem. Another argues space constraints make it impossible. Both are right—depending on the application. Understanding gate valve stem design is what separates a smooth project from costly rework.

Common User Pain Points

Limited Installation Space

Above-ground installations often have vertical clearance, while underground or compact chambers do not—making the wrong stem type a serious design flaw.

Unclear Valve Position

Operators may not instantly know whether a valve is fully open or closed, increasing the risk of operational errors.

Maintenance Difficulties

Incorrect stem choice can lead to premature wear, corrosion exposure, and increased service costs.

Practical Solutions & Expert Recommendations

Match Stem Type to Installation Environment

Use rising stem gate valves where visibility and maintenance access matter. Choose non-rising stem gate valves for buried or confined spaces.

Prioritise Operational Safety

Visible stem movement reduces human error, especially in critical isolation points.

Think Long-Term, Not Just Initial Cost

A cheaper valve with the wrong stem design often results in higher lifecycle costs.

Understanding Rising Stem Gate Valves

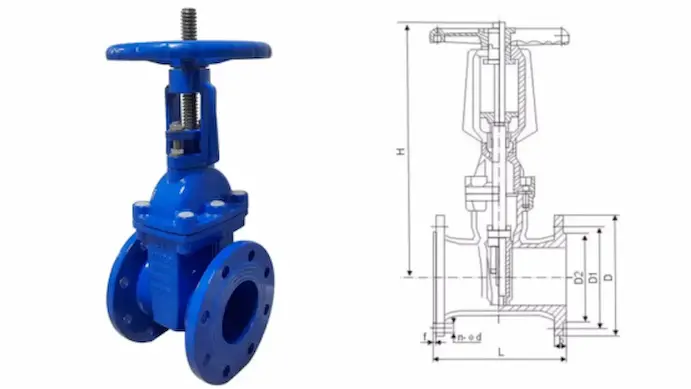

What Is a Rising Stem Gate Valve?

Our rising stem gate valve, also known as an OS&Y gate valve (Outside Screw and Yoke), features a stem that moves vertically when the valve opens or closes. The stem rises above the handwheel as the gate lifts.

Key Characteristics

-

Stem threads are outside the pressure boundary

-

Valve position is visually obvious

-

Better protection against internal corrosion

-

Requires additional vertical clearance

Typical Applications

-

Power plants

-

Oil & gas facilities

-

Chemical processing

-

Above-ground industrial pipelines

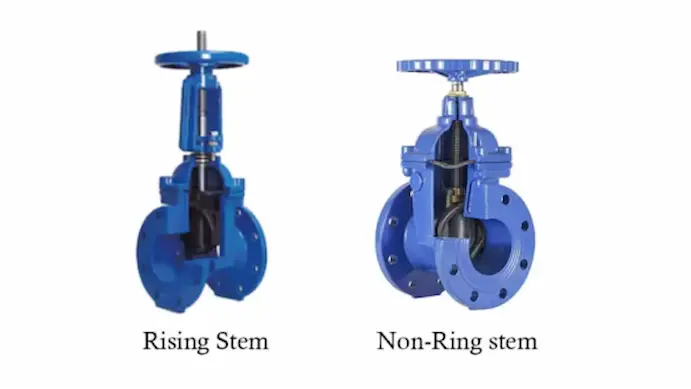

Understanding Non-Rising Stem Gate Valves

What Is a Non-Rising Stem Gate Valve?

Our non-rising stem gate valve, the stem rotates but does not move vertically. The gate travels internally along the stem threads.

Key Characteristics

-

Compact installation height

-

Stem threads exposed to media

-

Valve position not visually indicated

-

Ideal for underground service

Typical Applications

-

Water distribution networks

-

Fire protection systems

-

Underground pipelines

-

Valve pits and chambers

Rising Stem vs Non-Rising Stem Gate Valves

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

|---|---|---|

| Stem Movement | Vertical movement visible | Rotational only |

| Installation Space | Requires more vertical clearance | Compact height |

| Valve Position Indication | Clearly visible | Not visible |

| Stem Thread Location | Outside pressure boundary | Inside valve body |

| Maintenance Ease | Easier inspection | More difficult |

| Typical Use | Above-ground systems | Underground systems |

Case Study: Selecting the Wrong Stem Type

Case 1: Industrial Cooling System

A European plant installed non-rising stem valves above ground. Operators repeatedly misjudged valve positions, causing partial flow restrictions. After replacement with rising stem gate valves, operational errors dropped significantly.

Case 2: Municipal Water Network

A contractor used rising stem valves underground. Corrosion and clearance issues forced early replacement. Switching to non-rising stem gate valves resolved the problem.

Engineering Data & Performance Insights

From field data collected by Vcore Valve projects:

-

Visible stem indication reduces incorrect valve operation by over 30%

-

Underground stem corrosion accounts for 25% of premature gate valve failures

-

Proper stem selection can extend valve service life by 5–8 years

These figures highlight why gate valve stem design is not a minor detail—it is a system-level decision.

Market Trends & Industry Insights

-

Water utilities increasingly specify non-rising stem gate valves with corrosion-resistant coatings

-

Industrial plants favour OS&Y gate valves for safety compliance

-

Smart monitoring is driving demand for visual and mechanical position indicators

At Vcore Valve, we integrate these trends into product design and material selection.

Selection Tips from Vcore Valve Engineers

-

Choose rising stem gate valves when safety and visibility are priorities

-

Select non-rising stem gate valves for buried or space-restricted installations

-

Always consider maintenance access during design, not after commissioning

Conclusion

The difference between a rising stem and a non-rising stem gate valve is not subtle—it directly affects safety, reliability, and lifecycle cost. At Vcore Valve, we help clients select the right valve configuration for every application, backed by engineering expertise and proven manufacturing standards.

👉 Contact Vcore Valve today to discuss your gate valve requirements or request technical support.

FAQs

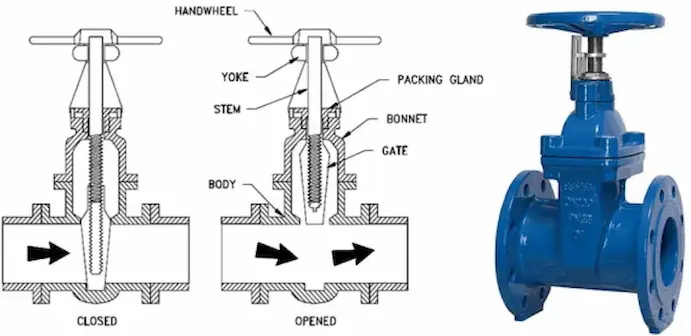

What is the main difference between rising and non-rising stem gate valves?

The key difference lies in stem movement: rising stems move vertically to show valve position, while non-rising stems rotate internally without visible indication.

Which gate valve is better for underground installation?

A non-rising stem gate valve is preferred due to its compact height and suitability for buried service.

Are rising stem gate valves easier to maintain?

Yes. External stem threads allow easier inspection, lubrication, and reduced corrosion risk.

Can non-rising stem valves be used above ground?

They can, but lack of visual position indication may increase operational risk.

Does stem type affect valve lifespan?

Absolutely. Incorrect stem selection is a common cause of premature gate valve failure.

What does OS&Y mean in gate valves?

OS&Y stands for Outside Screw and Yoke, another term for rising stem gate valves.

Reference

-

NSW Valve – Rising Stem vs Non-Rising Stem Gate Valve

-

Crane Co. – Gate Valve Design and Applications

-

Engineering Toolbox – Gate Valve Types