Quick Summary

Efficient ball valve operation depends not only on valve design, but also on the tools used to operate it. Our ball valve wrenches may appear simple, yet improper selection or usage can cause stem damage, excessive torque, or even complete valve failure. At Vcore Valve, we regularly see performance issues traced back to incorrect valve tools. This article explains ball valve wrenches in a practical, engineering-focused way.

A Real-World Workshop Scenario

“The valve is too tight.”

“Just use a longer wrench.”

That single decision has damaged more valve stems than most people realise.

Key User Pain Points

Applying Excessive Torque

Using the wrong wrench length often leads to over-torque and stem deformation.

Poor Ergonomics and Safety

Improvised tools increase the risk of hand injuries and uncontrolled movement.

Lack of Tool–Valve Compatibility

One wrench does not fit all ball valves, despite common assumptions.

Practical Solutions and Expert Advice

Match the Wrench to Valve Size and Torque

Select tools based on valve DN and operating torque, not convenience.

Use Dedicated Ball Valve Wrenches

Purpose-built tools reduce damage and improve efficiency.

Train Operators Properly

Correct operation technique extends valve service life.

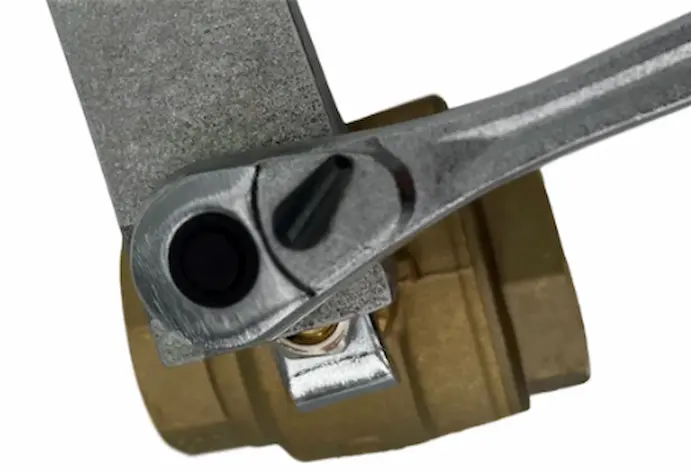

What Is a Ball Valve Wrench?

A ball valve wrench is a manual tool designed to open or close ball valves by applying controlled torque to the valve stem or handle. Unlike generic spanners, valve wrenches are engineered to deliver force evenly while minimising stress on internal components.

At Vcore Valve, we treat valve tools as part of the valve system, not accessories.

Common Types of Ball Valve Wrenches

Standard Handle Wrenches

Typically supplied with small manual ball valves.

Best for:

-

Low torque applications

-

Small bore valves

Adjustable Valve Wrenches

Designed for multiple valve sizes.

Advantages:

-

Flexibility

-

Reduced tool inventory

Limitations:

-

Less precise torque control

T-Handle and Cross Wrenches

Used where higher torque is required.

Key benefit:

Improved leverage without excessive strain.

Ball Valve Torque Explained

Operating torque is influenced by:

-

Seat material

-

Line pressure

-

Temperature

-

Media characteristics

| Valve Type | Typical Torque Range |

|---|---|

| Soft seated ball valve | Low to medium |

| Metal seated ball valve | Medium to high |

| High-pressure ball valve | High |

Incorrect wrench selection magnifies torque-related problems.

Case Study: Over-Torqued Valve Failure

A processing plant reported frequent ball valve stem failures.

Investigation Findings:

-

Oversized wrench used

-

Torque exceeded design limits

Solution:

After switching to Vcore Valve recommended wrenches and torque guidelines, failures stopped completely.

Data and Engineering Analysis

Industry data indicates:

-

Over 40% of manual valve failures are tool-related

-

Proper wrench selection reduces maintenance incidents by up to 50%

-

Excess torque shortens seat life dramatically

Market Trends and Industry Insights

-

Growing focus on ergonomic valve tools

-

Increased awareness of manual torque limits

-

Integration of torque indicators into valve accessories

Usage and Selection Recommendations

-

Never use pipe extensions on valve handles

-

Match wrench length to torque requirements

-

Avoid impact force during operation

-

Inspect tools regularly for wear

Conclusion

A ball valve is only as reliable as the way it is operated.

At Vcore Valve, we design valves with clear torque guidelines and recommend proper ball valve wrenches to ensure long-term performance and safety.

👉 Contact Vcore Valve for ball valves and operation tools engineered to work together.

FAQs

Q1: Can I use a standard spanner as a ball valve wrench?

It is not recommended due to uneven load distribution.

Q2: Why is my ball valve hard to operate?

Possible causes include high line pressure or seat wear.

Q3: Does a longer wrench always help?

No. It often causes over-torque and damage.

Q4: Are ball valve wrenches universal?

No. They vary by size and torque rating.

Q5: How often should valve tools be inspected?

During routine maintenance cycles.

Q6: Does Vcore Valve supply valve operation tools?

Yes, with matching torque recommendations.

Reference

-

NSW Valve. Learn About Ball Valve Wrenches: A Key Tool for Efficient Ball Valve Operation

-

API 608. Metal Ball Valves – Flanged, Threaded and Welding Ends.

-

ISO 5211. Industrial Valves – Actuator Mounting.

-

Vcore Valve Technical Guide. Manual Valve Operation and Torque Control.