Quick Summary

Energy efficiency is no longer just an environmental concern—it is a financial necessity for modern industrial plants. One often overlooked contributor to energy consumption is valve selection. Ball valves, when properly designed and applied, can significantly reduce pressure loss, pumping energy and maintenance-related downtime. At Vcore Valve, we view ball valves not merely as isolation devices, but as strategic components in plant-wide energy optimisation.

A Realistic Plant Floor Conversation

“Why is our energy bill still rising after upgrading the pumps?”

“Because the valves are still wasting the energy you’re generating.”

Key User Pain Points

Hidden Energy Loss in Pipelines

Many plants focus on pumps and motors while ignoring pressure loss caused by inefficient valves.

Oversized or Incorrect Valve Selection

Incorrect valve bore or design creates turbulence and unnecessary resistance.

Short-Term Thinking in Procurement

Low upfront valve cost often leads to higher long-term energy consumption.

Practical Solutions from Vcore Valve

Choose Full Bore Flow Paths

Reducing flow restriction directly lowers pumping power demand.

Match Valve Design to Process Conditions

Not all ball valves perform the same under varying pressure and temperature.

Prioritise Lifecycle Efficiency

Energy-efficient valves pay for themselves over time.

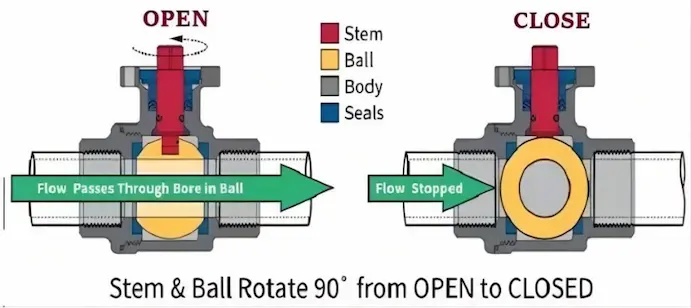

Why Ball Valves Are Naturally Energy Efficient

The core advantage of a ball valve lies in its straight-through flow design. When fully open, the bore aligns with the pipeline, allowing fluid to pass with minimal obstruction.

Energy-saving characteristics include:

-

Very low pressure drop

-

Reduced turbulence

-

Faster operation with minimal actuator energy

-

Lower leakage losses

This makes industrial ball valves ideal for energy-conscious facilities.

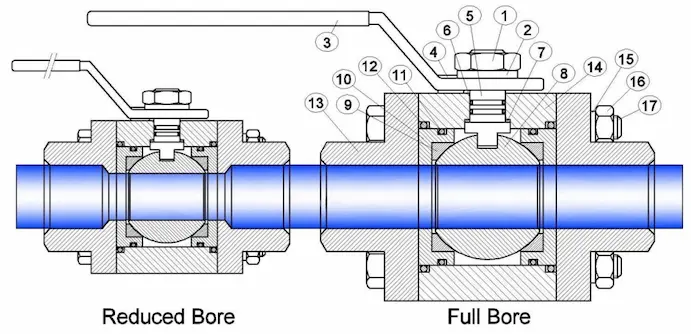

Full Bore vs Reduced Bore: The Energy Impact

A full bore ball valve maintains the same internal diameter as the pipe, minimising velocity change and friction loss.

| Valve Type | Pressure Loss | Energy Efficiency |

|---|---|---|

| Full bore ball valve | Very low | Excellent |

| Reduced bore ball valve | Moderate | Average |

| Globe valve | High | Poor |

At Vcore Valve, full bore designs are recommended for critical energy-saving applications.

Case Study: Chemical Processing Plant

A chemical plant experienced rising electricity costs despite modern pump systems.

Original configuration:

-

Reduced bore valves across main lines

Solution:

-

Replaced with Vcore Valve full bore ball valves

Result:

-

18% reduction in pump energy consumption

-

Lower system noise and vibration

-

Improved flow stability

Scientific and Data-Based Analysis

Studies show:

-

Every 10% increase in pressure loss can raise pumping energy by up to 7%

-

Ball valves typically have 70–80% lower flow resistance than globe valves

-

Energy-efficient valve selection can reduce total plant energy usage by 5–12%

These figures highlight why valve choice matters in energy audits.

Industry Trends and Market Insights

-

Growing adoption of energy-efficient valves in ISO 50001-certified plants

-

Increased demand for low pressure drop ball valves

-

Integration of valve performance into digital energy monitoring

-

Sustainability reporting driving valve replacement programmes

Best Practices for Energy-Efficient Valve Use

-

Use full bore ball valves on main process lines

-

Avoid oversized valves that increase turbulence

-

Ensure smooth actuator operation to minimise power draw

-

Schedule regular maintenance to prevent leakage-related losses

Conclusion

Energy efficiency is not achieved by one component alone—it is the result of intelligent system design. Ball valves, when correctly selected, play a crucial role in reducing pressure loss, pump load and operational energy costs.

At Vcore Valve, we design and supply energy-efficient ball valves engineered for real industrial performance, not just catalogue specifications.

👉 Contact Vcore Valve today to optimise your valve selection and reduce plant energy consumption.

FAQs

Q1: Are ball valves more energy efficient than gate valves?

Yes, particularly full bore ball valves, due to lower pressure loss.

Q2: Does valve size affect energy efficiency?

Absolutely. Incorrect sizing increases turbulence and energy waste.

Q3: Can upgrading valves really reduce energy bills?

Yes, especially in pump-driven systems.

Q4: Are automated ball valves less efficient?

Modern actuators are highly efficient and often improve control accuracy.

Q5: Which industries benefit most from energy-efficient ball valves?

Chemical, oil & gas, water treatment, and power generation.

Q6: Does Vcore Valve offer energy-optimised valve designs?

Yes, tailored to specific process conditions.

Reference

-

NTGD Valve. How Ball Valves Contribute to Energy Efficiency in Industrial Plants

-

ISO 5167. Measurement of Fluid Flow by Means of Pressure Differential Devices.

-

Hydraulic Institute. Energy Assessment Guidelines for Pumping Systems.

-

Vcore Valve Technical Whitepaper. Flow Efficiency and Pressure Loss in Ball Valves.