Quick Overview

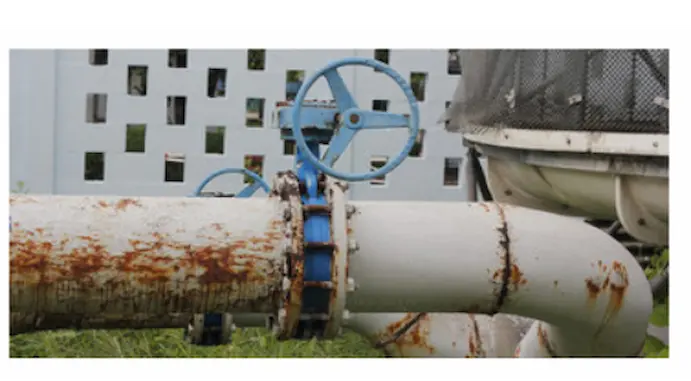

Our leaking butterfly valve is more than a nuisance—it signals potential sealing failure, efficiency loss, and unplanned downtime. Whether the leak appears around the seat, shaft, or flange, the root cause is often predictable and preventable. This in-depth guide from Vcore Valve explains why butterfly valves leak, how to fix them correctly, and how to avoid repeat failures in industrial systems.

Opening Scenario: A Familiar Maintenance Call

“The valve was installed last year—why is it already leaking?”

“We tightened the bolts, but it’s still dripping.”

In many cases, the issue isn’t installation alone—it’s a combination of wear, misalignment, and material mismatch.

Common User Pain Points

Persistent Leakage After Tightening

Over-tightening flange bolts often worsens seat deformation instead of stopping leaks.

Unexpected Downtime

A minor leak can escalate into production stoppage or safety hazards.

Short Valve Service Life

Improper maintenance or incorrect valve selection leads to premature failure.

Practical Solutions and Expert Recommendations

Identify the Exact Leak Location

Seat leakage, shaft leakage, and body leakage require different repair approaches.

Use Correct Replacement Materials

Seat and seal materials must match temperature, pressure, and media.

Follow Manufacturer Torque Guidelines

Random tightening is one of the leading causes of butterfly valve leakage.

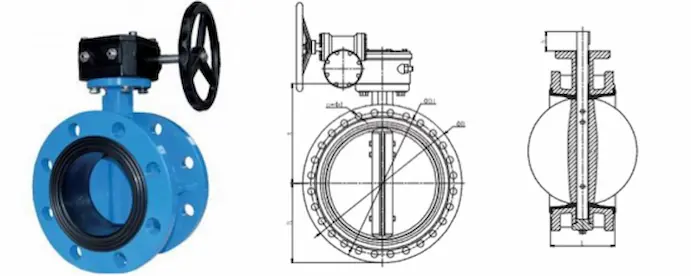

Where Does a Butterfly Valve Leak From?

Seat Leakage

The most common issue, usually caused by worn or damaged elastomer seats.

Shaft Leakage

Often results from ageing O-rings or packing deterioration.

Flange or Body Leakage

Typically linked to misalignment, gasket damage, or uneven bolt loads.

Main Causes of a Leaking Butterfly Valve

Worn or Damaged Seat

Frequent cycling, abrasive media, or chemical attack degrade sealing surfaces.

Incorrect Installation

Improper centring between flanges can permanently deform the seat.

Excessive Operating Pressure

Operating beyond rated pressure compromises sealing integrity.

Corrosion or Erosion

Common in stainless steel butterfly valves used in aggressive environments.

Step-by-Step: How to Fix a Leaking Butterfly Valve

Step 1: Isolate and Depressurise

Always fully isolate the pipeline and release pressure before inspection.

Step 2: Inspect the Seat and Disc

Look for cuts, flattening, or chemical damage on the seat.

Step 3: Replace the Seat or Seal

In most cases, butterfly valve seat replacement restores tight shut-off.

Step 4: Check Shaft Seals

Replace worn O-rings or packing if leakage is around the stem.

Step 5: Reinstall with Proper Alignment

Centre the wafer butterfly valve carefully before tightening bolts.

Repair vs Replacement: A Cost Comparison

| Condition | Repair Suitable | Replacement Recommended |

|---|---|---|

| Minor seat wear | ✅ | ❌ |

| Severe corrosion | ❌ | ✅ |

| Repeated leakage | ❌ | ✅ |

| Shaft damage | ❌ | ✅ |

Replacing a valve early is often cheaper than repeated emergency repairs.

Case Study: Food Processing Plant Failure

A dairy facility experienced recurring leakage in EPDM-seated butterfly valves. Investigation revealed cleaning chemicals exceeded material compatibility. After switching to PTFE-lined valves supplied by Vcore Valve, leakage incidents dropped by over 70% within one year.

Data and Engineering Insights

-

Over 60% of butterfly valve leaks are seat-related

-

Misalignment increases leakage risk by up to 40%

-

Correct torque application extends seat life by 30–50%

Preventive maintenance consistently outperforms reactive repair.

Industry Trends and Market Insights

Modern butterfly valves increasingly feature:

-

Replaceable cartridge seats

-

Low-friction coatings

-

Improved stem sealing systems

-

Automation-compatible designs

These advancements significantly reduce leakage risk in high-cycle applications.

Usage and Maintenance Tips

-

Operate valves fully open or closed—avoid throttling unless designed for it

-

Schedule regular inspections for high-cycle systems

-

Keep records of seat material and service conditions

-

Always follow manufacturer torque specifications

Conclusion and Call to Action

A leaking butterfly valve is rarely random—it’s a predictable result of wear, misapplication, or installation error. By understanding the causes and applying correct repair methods, operators can significantly extend valve life and reduce downtime.

Vcore Valve offers engineered butterfly valves with optimised sealing, durable materials, and expert technical support.

👉 Contact our team today for leakage-free valve solutions tailored to your application.

FAQs

Why is my butterfly valve leaking when closed?

Most likely due to worn seats, debris on the sealing surface, or misalignment.

Can a leaking butterfly valve be repaired?

Yes, if the damage is limited to seats or seals.

How long should a butterfly valve seat last?

Typically 3–10 years depending on media and cycle frequency.

Does over-tightening stop leakage?

No, it often worsens seat deformation.

When should I replace instead of repair?

If corrosion, disc damage, or repeated leakage occurs.

Are stainless steel butterfly valves leak-proof?

They are corrosion-resistant but still rely on proper sealing materials.

References

-

ISO 5208 – Industrial Valve Pressure Testing

-

ASME B16.34 – Valves Flanged, Threaded and Welding End

-

Engineering Toolbox – Valve Leakage Causes

-

Valve World Magazine – Butterfly Valve Maintenance Practices

-

Fluid Sealing Association – Elastomer Seat Performance