Quick Summary

When deciding between a needle valve and a ball valve, it’s important to understand how each type performs in terms of flow control, precision, pressure resistance and sealing performance. At Vcore Valve, we often see misapplications because buyers choose based on price or familiarity rather than function. This guide explains the key differences, advantages, and suitable applications for both valve types so you can make a confident and cost-effective choice.

Opening Scenario: A Common Engineering Dilemma

“I need precise flow adjustment on this instrumentation line, but a ball valve seems simpler and cheaper. Can I use it instead?”

“Not always — the choice between a needle valve and a ball valve can determine the performance and longevity of your system.”

Many engineers face this exact dilemma when specifying valves for industrial, instrumentation, or control systems.

User Pain Points

Inadequate Flow Control

Ball valves function well as on/off devices, but they lack the fine control needed in systems where precise throttling is critical. This can lead to overshoot, system instability, or inefficient operations.

Misuse Leads to Premature Wear

Using a ball valve for precision flow applications often results in high friction, wear, and increased maintenance cost — because ball valves are designed for duty cycles different to those in metering or balancing tasks.

Confusion Over Valve Selection

Many professionals find it difficult to choose the right valve due to overlapping functions. Without a clear understanding, the wrong valve often gets specified, leading to downstream problems.

Solutions & Recommendations

Understand Functional Design

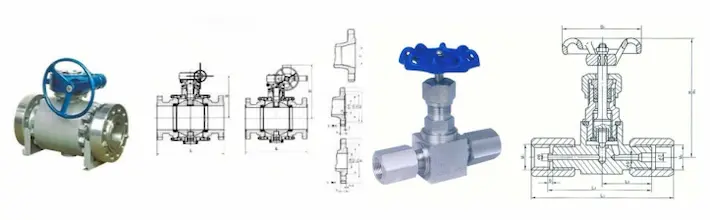

Needle valves are designed for precision adjustment of flow, often used in instrumentation, calibration, and metering applications. Ball valves are best for rapid shut-off or full-flow conditions.

Match Valve to Operating Conditions

Assess pressure, temperature, media type and desired control behaviour before selecting a valve. For low-flow precise control, a needle valve usually wins; for simple open/close applications, the ball valve is ideal.

Choose Quality Materials

At Vcore Valve, materials are selected to match your process conditions — from stainless steel for corrosion resistance to high-pressure capable alloys for demanding systems.

Case Studies

Case 1 – Instrumentation Loop Accuracy

In an upstream gas facility, switching from ball valves to high-pressure needle valves improved measurement stability and reduced unnecessary venting by over 15%.

Case 2 – Chemical Process Shut-Off

A chemical plant using stainless steel ball valves for line isolation saw improved reliability and easier maintenance in corrosive environments.

Data & Technical Comparison

| Parameter | Needle Valve | Ball Valve |

|---|---|---|

| Primary Function | Precise flow regulation | On/Off shut-off |

| Flow Control | Excellent | Poor |

| Pressure Drop | Higher | Lower |

| Operating Torque | High | Low |

| Sealing | Good | Excellent |

| Typical Use | Instrumentation, calibration | Isolation, full-flow |

| Wear under frequent use | Medium | Depends on seat material |

The design of needle valves — with long tapered stems — facilitates fine adjustment of flow rates, while ball valves provide tight sealing and easy quarter-turn operation.

Market Trends & Industry Insights

-

Growing preference for precision flow control in modern process automation

-

Increased adoption of stainless steel ball valves due to corrosion resistance

-

Rise in demand for high-pressure needle valves in oil & gas and test equipment

-

Integration of smart sensors and actuators for automated valve control

At Vcore Valve, we anticipate continued blending of automation with precision hardware in critical control loops.

Usage & Selection Tips

-

Use needle valves for fine control, calibration lines, and instrumentation systems

-

Use ball valves for general isolation, large flow capacity, and fast shut-off

-

Always check pressure rating, flow coefficient (Cv), and material compatibility

-

Avoid using ball valves for throttling — this accelerates wear

Conclusion & Call to Action

Understanding the differences between a needle valve vs ball valve ensures you select the right valve for performance, reliability, and cost-effectiveness. Whether you need fine flow control or rapid shut-off, Vcore Valve has a solution for your system.

👉 Contact Vcore Valve today for technical assistance, customised drawings, and expert valve recommendations.

FAQ

Q1: What is the main difference between a needle valve and a ball valve?

Needle valves are designed for precise flow control, while ball valves are designed for fast shut-off and full-flow capability.

Q2: Can a ball valve be used for flow regulation?

No, ball valves are not suitable for precision flow regulation; they are best used as isolation devices.

Q3: Where are needle valves commonly used?

Needle valves are commonly used in instrumentation, calibration systems, and process control loops where fine adjustment is required.

Q4: Are ball valves suitable for high-pressure applications?

Yes, ball valves, especially stainless steel ones, are widely used in high-pressure industrial systems.

Q5: How do I choose between a needle valve and a ball valve?

Selection depends on flow control needs, pressure, temperature, and media type — needle valves for precision, ball valves for isolation and fast operation.

References

-

ISO 15848-1 – Industrial valves — Measurement, test and qualification procedures for fugitive emissions

International Organization for Standardization (ISO) -

ASME B16.34 – Valves — Flanged, Threaded, and Welding End

American Society of Mechanical Engineers (ASME) -

API 598 – Valve Inspection and Testing

American Petroleum Institute (API) -

ISA – Control Valve Handbook

International Society of Automation

Authoritative guidance on valve flow characteristics, throttling behaviour, and control applications. -

Engineering Toolbox – Valve Flow Coefficient (Cv)

Widely referenced engineering resource explaining flow coefficients and pressure drop in valves. -

Crane Technical Paper No. 410 – Flow of Fluids Through Valves, Fittings, and Pipe

Industry-standard reference for fluid flow analysis and valve performance comparison. -

Vcore Valve Technical Documentation

Internal engineering data, application experience, and field performance records from industrial valve projects.