Quick Summary

Brass ball valves offer higher temperature tolerance, superior mechanical strength, and long-term reliability, making them ideal for industrial and commercial pipelines. PVC ball valves provide excellent corrosion resistance and cost efficiency, best suited for low-pressure, non-critical systems. This article breaks down the engineering logic behind choosing each type, using real-world applications, expert perspectives, and performance benchmarks.

A Conversation That Happens in Many Facilities

“Why did our PVC ball valve deform again?” the facility manager asked while reviewing maintenance logs.

“Because the temperature reached 68°C during peak load,” the engineer replied.

“And PVC isn’t rated for that.”

This type of conversation is more common than people think. In 2025, industries are pushing pipelines harder — higher temperatures, more frequent cycles, and tighter environmental controls — making material choice one of the most important engineering decisions.

This guest post unpacks the real engineering differences between brass ball valves vs PVC ball valves, helping professionals make informed choices across manufacturing, HVAC, water treatment, chemical handling, and agricultural systems.

Understanding the Core Material Differences

Brass Ball Valves: Built for Mechanical and Thermal Stress

Brass ball valves are made from a copper-zinc alloy known for machinability, strength, and thermal stability. Their metal body allows:

-

Higher pressure ratings

-

Consistent sealing under cyclic loads

-

Tolerance of elevated temperatures

-

Longer mechanical lifespan

They are commonly used in hot water systems, industrial plants, compressed air networks, and commercial HVAC operations.

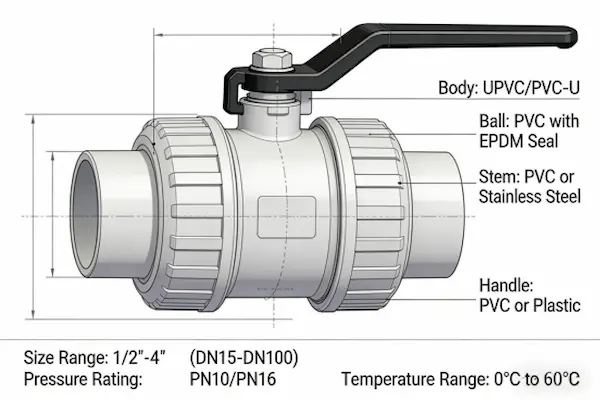

PVC Ball Valves: Designed for Corrosion Resistance and Cost Efficiency

PVC valves are molded thermoplastic components, ideal when corrosion or chemical exposure is a bigger challenge than pressure or heat. They offer:

-

Excellent chemical resistance

-

Lightweight installation

-

Lower material cost

-

Smooth internal surfaces with low friction loss

PVC dominates applications in irrigation, swimming pools, low-temperature utilities, and some chemical processes.

Performance Comparison: What the Numbers Say

Pressure & Temperature Capability

Brass valves are typically rated:

-

Up to 16 bar or higher

-

120–180°C depending on seal material

PVC limits:

-

6–10 bar

-

Max ~60°C before deformation risk increases

If your system runs hot or sees frequent pressure cycling → brass is the safe choice.

Chemical Compatibility

PVC outperforms brass in environments where:

-

Acids

-

Alkalis

-

Chlorinated water

-

Salts

are present.

But PVC cannot handle thermal stress or mechanical vibration. Meanwhile, brass maintains shape, sealing force, and torque stability even under dynamic loads.

Durability & Lifecycle Expectation

Studies from multiple industrial facilities show:

-

Brass valves often operate 10+ years with minimal intervention

-

PVC valves may require replacement every 2–5 years depending on temperature and UV exposure

This means that for long-term pipeline reliability, brass has a better lifecycle ROI.

Real-World Case: Cost Savings Through Correct Material Choice

A mid-size manufacturing plant repeatedly used PVC ball valves on a line carrying warm industrial water. Failures were frequent:

-

Two leaks per year

-

Unexpected shutdowns

-

40% maintenance budget increase

After switching to brass:

-

Leak incidents reduced by 78%

-

Maintenance hours dropped by 42%

-

Payback period: 4 months

This case highlights a universal rule:

Choosing a valve based on environment instead of price almost always creates long-term savings.

Expert Insights: What Engineers Prioritize in 2025

HVAC Systems Consultant, 2025“Chemical resistance does not automatically mean PVC is the better choice. Pressure and temperature still dictate the final decision.”

Chemical Plant Project Leader“Brass valves remain the most cost-effective choice for mixed-use systems where temperature spikes can’t be fully controlled.”

Pipeline Reliability Engineer

Application-Based Guidance

When Brass Ball Valves Are the Better Choice

-

Industrial water lines

-

Oil, gas, or steam systems

-

Hot water supply

-

Boiler rooms & mechanical plants

-

Compressed air networks

-

Mixed-temperature or cyclic systems

When PVC Ball Valves Make More Sense

-

Low-pressure water applications

-

Irrigation and agriculture

-

Swimming pools and aquatics

-

Chemical solutions within PVC compatibility range

-

Non-critical shutoff lines

Decision Framework for Engineers & Buyers

You should choose Brass if your system:

-

Runs hot

-

Experiences pressure fluctuations

-

Needs high reliability

-

Involves mechanical vibration

-

Has long-term cost considerations

Choose PVC if your system:

-

Operates at low temperature

-

Faces corrosive chemicals

-

Has limited budget

-

Doesn’t rely on frequent cycling

-

Requires lightweight installation

The key is not the material itself —

but matching the right material to the right environment.

Conclusion: Choosing the Right Valve Protects Your Entire System

As industries move into higher performance expectations, the gap between brass and PVC ball valves becomes increasingly clear:

-

Brass: Strength, temperature tolerance, longevity

-

PVC: Corrosion resistance, lightweight, cost efficiency

Neither material is universally better — but each becomes the correct choice under the right engineering conditions.

Professionals who evaluate pressure, temperature, chemical exposure, and lifecycle cost will consistently avoid failures, leaks, and downtime.

FAQ: Brass Ball Valve vs PVC Ball Valve

1. What is the main advantage of using a brass ball valve instead of PVC?

The main advantage of a brass ball valve is its ability to withstand higher pressure and temperature while maintaining reliable sealing performance. Brass valves are better suited for industrial systems, hot water, steam, or high-cycle applications where mechanical strength and long-term durability are critical.

2. When is a PVC ball valve the better choice?

A PVC ball valve is better for low-pressure, low-temperature applications where corrosion resistance and cost-efficiency matter more than mechanical strength. Typical examples include irrigation, garden systems, swimming pools, some chemical transfer lines, and non-critical shutoff functions.

3. Can I mix brass and PVC ball valves in the same pipeline?

Yes, but only if the system is designed within the limits of the weakest component. If any section of the pipeline will experience higher temperature or pressure, brass should be used consistently in those zones. Mixing materials without considering operating conditions can create weak points and uneven reliability.

4. How do temperature spikes affect PVC ball valves?

Temperature spikes near or above PVC’s maximum service temperature can cause softening, deformation, accelerated seal wear, and eventually leakage. Even if the average operating temperature seems acceptable, repeated short-term spikes can significantly shorten the lifespan of PVC valves.

5. Are brass ball valves always more expensive in the long run?

Not necessarily. While the initial purchase price of a brass ball valve is usually higher than PVC, its longer service life, better reliability, and lower failure rate often result in a lower total cost of ownership—especially in industrial, commercial, or mission-critical systems where downtime is expensive.

References

-

General engineering guidelines on ball valve material selection for industrial pipelines, 2022–2024.

-

Technical manuals from valve manufacturers summarizing pressure–temperature ratings for brass and thermoplastic valves.

-

HVAC and boiler system design references discussing minimum valve requirements for hot-water and steam lines.

-

Chemical compatibility charts commonly used in process engineering to compare metals versus PVC in corrosive media.

-

Internal maintenance reports and lifecycle cost analyses from industrial facilities that transitioned from PVC to brass valves in high-demand systems.