Quick Overview

Brass check valves are integral components in fluid and gas systems, preventing backflow to maintain system integrity. This article covers everything you need to know about brass check valves, including how they work, their types, applications, and the best practices for installation and maintenance. At Vcore Valve, we offer high-quality brass check valves designed to meet various industry standards.

Opening Scenario

“Why is backflow prevention so important in my system?”

“How can I be sure that my brass check valve is functioning properly?”

In many industrial and plumbing systems, backflow can cause contamination, damage to equipment, or system failures. Brass check valves are specifically designed to prevent this reverse flow. Let’s break down how these valves work and why choosing the right one is critical for your application.

User Pain Points

Understanding Backflow Prevention

Backflow in fluid systems can lead to contamination, corrosion, and damage to equipment, leading to expensive repairs and downtime. Many systems suffer because the right backflow preventer isn’t selected.

Choosing the Right Valve Type

With so many types of check valves available, such as swing, ball, and lift valves, it’s easy to make the wrong choice. Many buyers struggle to understand the differences and select a valve that doesn’t meet the system’s requirements.

Valve Durability and Maintenance

Brass check valves that are improperly maintained or made from subpar materials can degrade quickly, leading to failures. Regular maintenance is essential to ensure they continue to function correctly over time.

Solutions & Expert Recommendations

Understand the Types of Check Valves

There are various types of brass check valves, each suited for different applications:

-

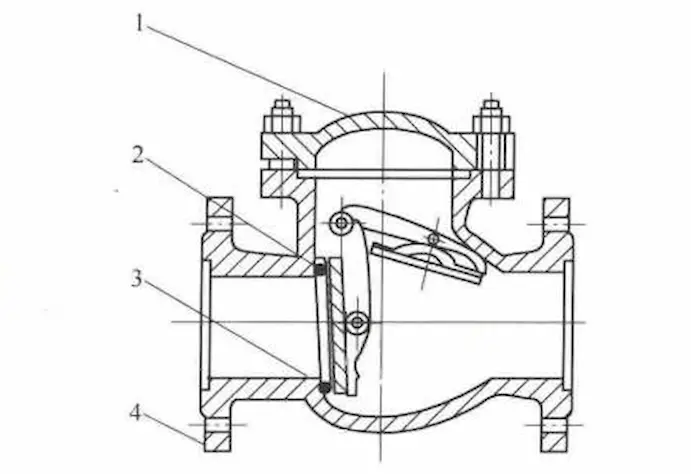

Swing Check Valves: Ideal for horizontal flow systems.

-

Lift Check Valves: Best for vertical applications.

-

Ball Check Valves: Compact and used for small-scale systems.

Choosing the right type based on your system’s layout and fluid type is critical.

Regular Maintenance and Inspections

Ensure your brass check valves are regularly cleaned and inspected. Maintenance helps prevent corrosion, build-up, or debris that could interfere with the valve’s performance.

Choose Quality Brass Valves

Opt for high-quality, lead-free brass alloys that offer superior corrosion resistance and durability. At Vcore Valve, we offer brass check valves designed to meet the highest industry standards, ensuring your systems stay functional and safe.

Case Studies/Examples

Case 1 – Industrial Water Treatment

A manufacturing plant had recurring issues with backflow and contamination. After switching to Vcore Valve’s high-performance brass check valves, they saw a dramatic reduction in system failures, improving both efficiency and safety.

Case 2 – HVAC System

In an HVAC system, replacing the outdated check valves with Vcore Valve’s brass models ensured better flow control and eliminated costly repairs.

Data & Technical Comparison

| Valve Type | Flow Control | Pressure Drop | Application |

|---|---|---|---|

| Brass Ball Valve | On/Off | Low | Water, Gas |

| Brass Swing Valve | Automatic | Moderate | Backflow |

| Brass Lift Valve | Automatic | High | Vertical Systems |

| Brass Check Valve | Automatic | Low | Fluid Regulation |

Market Trends & Insights

-

Increasing Demand for Brass Valves: Brass valves are increasingly being preferred in water treatment, HVAC, and industrial applications due to their superior durability, corrosion resistance, and cost-effectiveness.

-

Lead-Free Brass: With stricter regulations on lead in drinking water, many industries are turning to lead-free brass alloys like CW617N for their valves.

-

Smart Valve Technology: IoT-enabled valves are becoming a trend in smart systems, providing real-time data and control for optimal performance.

Usage & Style Tips

-

Always ensure your brass check valve is rated for the specific pressure and temperature conditions of your system.

-

Use swing check valves for low-pressure, horizontal flow systems.

-

For vertical flow systems, lift check valves are often the best option.

Conclusion

Choosing the right brass check valve is essential for maintaining the efficiency and safety of your system. At Vcore Valve, we offer a wide range of brass check valves designed to meet the highest performance standards. Whether you’re dealing with backflow prevention, water control, or fluid regulation, our valves provide the reliability and durability you need.

👉 Contact Vcore Valve today for technical drawings, samples, and expert recommendations.

FAQ – Brass Check Valves

Q1: What is a brass check valve used for?

A: Brass check valves are primarily used to prevent backflow in fluid and gas systems, ensuring the proper flow direction and preventing contamination.

Q2: How do I know which brass check valve to choose?

A: The type of brass check valve you choose depends on your system’s requirements. Swing, lift, and ball check valves are commonly used, each suited for different flow conditions and system configurations.

Q3: How do I maintain my brass check valve?

A: Regular maintenance includes cleaning and inspection to prevent debris build-up and corrosion. This helps ensure long-term performance and avoids unexpected failures.

Q4: Are brass check valves durable?

A: Yes, brass check valves are highly durable and corrosion-resistant, especially when made from high-quality alloys. However, regular maintenance is necessary to ensure their longevity.

Q5: Can brass check valves handle high-pressure systems?

A: Brass check valves can handle various pressure conditions, but it’s important to choose a valve with the appropriate pressure rating for your specific system.