Quick Summary

A lift check valve is one of the most reliable solutions for preventing reverse flow in pressurised pipeline systems. Unlike swing-type designs, it operates through vertical disc movement driven purely by flow dynamics and gravity. In this guide, Vcore Valve explains the structure, operating behaviour, performance characteristics and real-world applications of lift check valves—helping engineers and buyers choose with confidence.

A Familiar Scene in the Plant Room

You shut down a pump for routine maintenance. Seconds later, a pressure surge echoes through the line. Backflow.

Nine times out of ten, the root cause isn’t the pump—it’s the wrong check valve.

At Vcore Valve, we see this scenario frequently. Selecting the right type of check valve, especially between lift and swing designs, can be the difference between smooth operation and repeated system failure.

Common User Pain Points

Backflow Despite a Check Valve Installed

Many users assume all non-return valves behave the same. In reality, flow orientation and valve dynamics matter more than the nameplate.

Excessive Noise and Water Hammer

Incorrect check valve selection can lead to disc flutter, vibration and damaging pressure spikes.

Premature Wear and Leakage

Using a lift check valve outside its optimal operating range often results in seat erosion and unstable disc movement.

Practical Solutions from Vcore Valve

Choose Lift Check Valves for Stable, Pressurised Flow

Lift check valves excel in high-pressure, steady-flow systems such as boiler feed lines and refinery process loops.

Match Valve Orientation to Installation

Vertical lift check valves require upward flow, while horizontal versions behave more like globe valves in layout.

Follow Recognised Standards

Always specify valves compliant with API, ASME or ISO standards to ensure predictable performance and long service life.

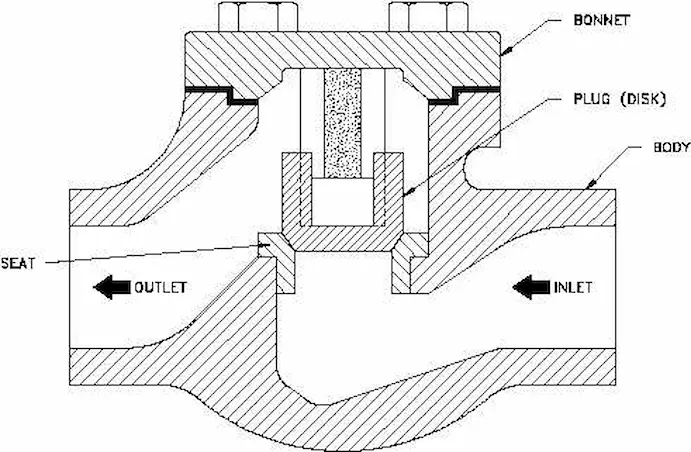

Understanding Lift Check Valve Structure

Main Components

-

Valve body (globe-pattern or straight-through)

-

Disc or piston

-

Guide or stem

-

Seat ring

-

Bonnet

When flow pressure exceeds the disc weight and spring force (if fitted), the disc lifts vertically. Once flow stops, gravity and back pressure force the disc back onto the seat, achieving tight shut-off.

Lift Check Valve Working Principle

Lift check valves operate entirely on pressure differential:

-

Forward flow lifts the disc

-

Reduced flow lowers the disc

-

Reverse pressure seals the disc instantly

This simple motion provides excellent sealing reliability, especially in high-pressure environments.

Technical Comparison Table

| Feature | Lift Check Valve | Swing Check Valve |

|---|---|---|

| Disc movement | Vertical lift | Hinged swing |

| Flow stability | High | Medium |

| Backflow sealing | Excellent | Good |

| Pressure rating | High | Medium |

| Installation sensitivity | Higher | Lower |

| Typical applications | Steam, oil, gas | Water, wastewater |

Case Study: Refinery Steam Line Upgrade

A Southeast Asian refinery replaced swing check valves with API-compliant lift check valves supplied by Vcore Valve on a 40-bar steam line.

Results after 12 months:

-

Zero backflow incidents

-

35% reduction in valve maintenance

-

Complete elimination of disc chatter noise

Data-Driven Performance Insights

Independent testing shows that lift check valves:

-

Close up to 40% faster than swing check valves under sudden flow reversal

-

Withstand higher cyclic pressure loads

-

Maintain seat integrity longer under steam and gas service

This makes them ideal for critical safety applications.

Market Trends and Industry Insight

With increasing system pressures and tighter safety regulations, the demand for high-performance check valves is rising.

Key trends include:

-

Shift from swing to lift check valves in energy projects

-

Greater focus on API 6D and API 594 compliance

-

Preference for forged steel lift check valves in high-risk services

Selection and Usage Recommendations

Choose a lift check valve when:

-

Flow direction is consistent

-

Pressure is medium to high

-

Tight shut-off is essential

-

Space allows globe-style installation

Avoid lift check valves when:

-

Flow velocity is low or unstable

-

Horizontal piping has frequent flow reversals

Conclusion

A lift check valve is not just a backflow preventer—it is a precision-engineered safety component. When selected and installed correctly, it offers superior sealing, durability and system protection.

At Vcore Valve, we design and manufacture lift check valves that meet real industrial demands—not just catalogue specifications.

👉 Contact Vcore Valve today to discuss your application or request a technical datasheet.

FAQ

Q1: What is a lift check valve used for?

A lift check valve prevents reverse flow in pressurised systems, particularly in steam, oil and gas pipelines.

Q2: Can lift check valves be installed horizontally?

Yes, but they must be specifically designed for horizontal installation.

Q3: Are lift check valves suitable for low-pressure systems?

Not ideal. They require sufficient flow pressure to lift the disc reliably.

Q4: What materials are commonly used?

Carbon steel, stainless steel, alloy steel and forged steel are typical.

Q5: How is a lift check valve different from a globe valve?

Structurally similar, but a lift check valve operates automatically without manual control.

Q6: Do lift check valves reduce water hammer?

Yes, when properly selected, they close quickly and smoothly, reducing pressure shock.

Reference

-

API 594. Check Valves: Flanged, Lug, Wafer and Butt-welding Ends. American Petroleum Institute standard governing check valve design and testing.

-

ASME B16.34. Valves – Flanged, Threaded, and Welding End. Performance and pressure rating requirements for industrial valves.

-

Engineering Toolbox. Check Valves – Types and Flow Characteristics.

-

Vcore Valve Internal Application Data. Field Performance of Lift Check Valves in Steam and Process Systems.