Quick Summary

Discussing pneumatic control valve vs hydraulic valve is not simply a matter of preference—it directly affects system reliability, response speed, safety and long-term operating cost. At Vcore Valve, we help engineers make this decision daily. This guide offers a clear, experience-based comparison to help you select the right valve actuation system for your application.

A Familiar Engineering Conversation

“We need fast response and low maintenance.”

“Yes, but the force requirement is huge.”

That single exchange explains why pneumatic and hydraulic valves continue to coexist in modern industry.

Key User Pain Points

Unsure Which System Fits the Application

Many projects fail because actuation force and control accuracy are misunderstood.

Unexpected Maintenance Costs

Hydraulic leaks or compressed air issues often appear after commissioning.

Safety and Environmental Concerns

Oil leakage and system contamination can become critical risks.

Practical Solutions and Selection Advice

Define Force, Speed and Accuracy First

Valve selection should begin with load and response requirements, not habit.

Match Actuation Type to Operating Environment

Clean rooms, explosive zones and outdoor installations demand different solutions.

Consider Lifecycle Cost, Not Just Purchase Price

Energy consumption and maintenance frequency matter more long-term.

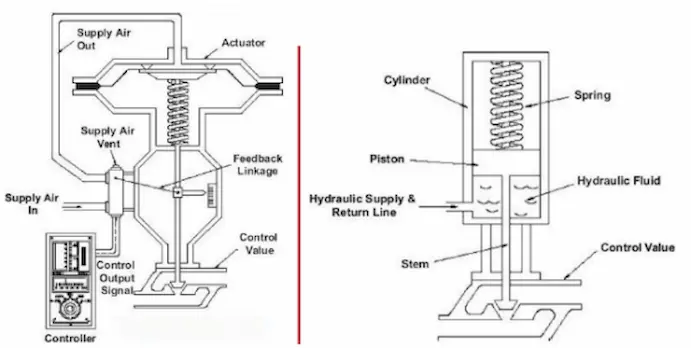

What Is a Pneumatic Control Valve?

A pneumatic control valve uses compressed air to actuate the valve, typically via a diaphragm or piston actuator. It is widely used in process control systems.

Key Characteristics

-

Fast response

-

Simple structure

-

Intrinsically safe in hazardous areas

-

Easy integration with automation systems

What Is a Hydraulic Valve?

A hydraulic valve uses pressurised hydraulic fluid to generate motion and force. It excels in high-load and heavy-duty applications.

Key Characteristics

-

Extremely high output force

-

Precise motion control

-

Suitable for harsh mechanical environments

-

Higher system complexity

Pneumatic Control Valve vs Hydraulic Valve: Technical Comparison

| Parameter | Pneumatic Control Valve | Hydraulic Valve |

|---|---|---|

| Power medium | Compressed air | Hydraulic oil |

| Output force | Medium | Very high |

| Response speed | Fast | Moderate |

| Control accuracy | Good | Excellent |

| System complexity | Low | High |

| Maintenance | Low | Higher |

| Environmental risk | Minimal | Oil leakage risk |

| Typical industries | Chemical, food, pharma | Heavy machinery, steel, mining |

Performance Analysis Based on Real Applications

Response Speed

Pneumatic systems outperform hydraulics in fast on-off and modulating control.

Force Capability

Hydraulic valves dominate where large actuating forces are required.

System Cleanliness

Pneumatics are preferred in food, pharmaceutical and clean-energy sectors.

Case Study: Chemical Processing Plant

A chemical plant initially selected hydraulic valves for reactor control. After frequent oil leakage and maintenance shutdowns, the system was converted to pneumatic control valves supplied by Vcore Valve.

Results:

-

Reduced maintenance by over 40%

-

Improved safety compliance

-

Faster valve response and control stability

Data-Driven Engineering Comparison

Industry data shows:

-

Pneumatic systems reduce maintenance costs by 30–50%

-

Hydraulic systems deliver up to 10× higher force output

-

Pneumatic valves account for over 70% of control valves in process industries

Industry Trends and Market Insights

-

Growing preference for pneumatic control valves in automation-heavy industries

-

Hydraulic systems remain essential in heavy-duty and mobile equipment

-

Increasing focus on energy efficiency and environmental safety

At Vcore Valve, pneumatic solutions dominate new automation projects, while hydraulic valves remain niche but critical.

Usage and Selection Recommendations

Choose pneumatic control valves if you need:

-

Fast response

-

Clean operation

-

Lower lifecycle cost

-

Simple maintenance

Choose hydraulic valves if you require:

-

Extremely high actuation force

-

Precise heavy-load control

-

Rugged mechanical performance

Conclusion

There is no universal winner between pneumatic and hydraulic valves—only the right choice for the right application. Understanding system demands is the key to long-term reliability.

At Vcore Valve, we don’t just sell valves—we help engineers make correct decisions.

👉 Contact Vcore Valve for expert advice on pneumatic and hydraulic valve solutions.

FAQs

Q1: Which is safer, pneumatic or hydraulic valves?

Pneumatic systems are generally safer due to the absence of oil leakage.

Q2: Are pneumatic control valves suitable for high pressure?

Yes, when properly designed and sized.

Q3: Why do hydraulic valves require more maintenance?

Oil contamination and leakage increase service requirements.

Q4: Can pneumatic valves achieve precise control?

Yes, especially with modern positioners.

Q5: Which system is more energy efficient?

It depends on duty cycle, but pneumatics often have lower operating costs.

Q6: Are hydraulic valves becoming obsolete?

No, they remain essential for heavy-duty applications.

Reference

-

NSW Valve. Comparison of Pneumatic Control Valve and Hydraulic Valve.

-

ISA. Control Valve Handbook.

-

ISO 4414 & ISO 4413. Hydraulic and Pneumatic System Safety Standards.

-

Vcore Valve Engineering Guide. Valve Actuation and Automation