Quick Summary

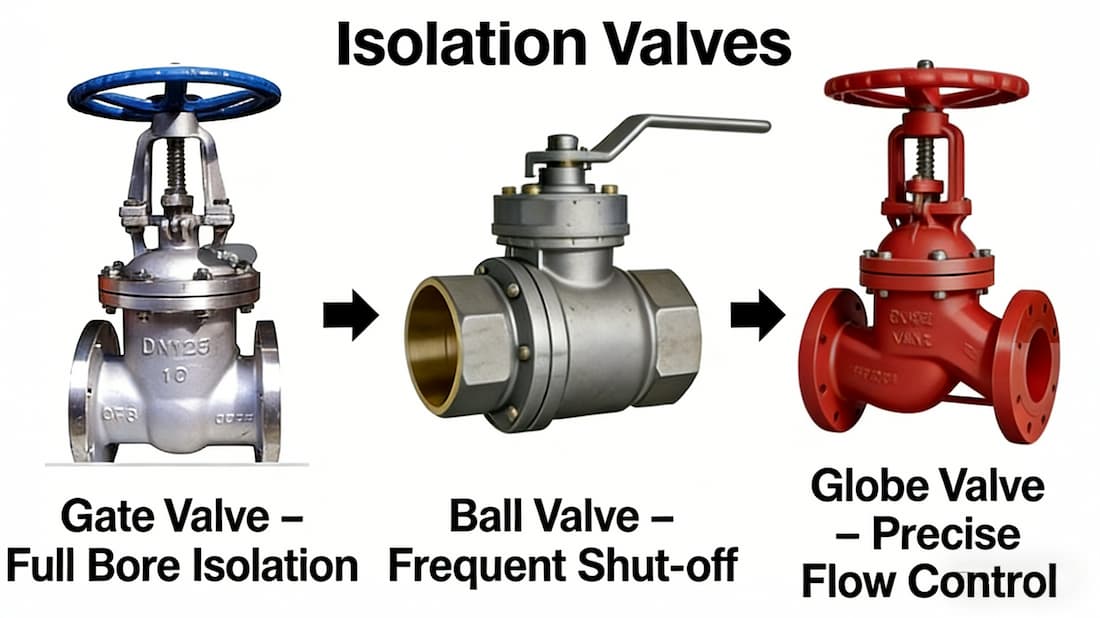

Isolation valves, designed to control flow, enable maintenance, and ensure safety, include Gate Valves as a specific type. Gate valves, a type of isolation valve, are widely used in industrial piping systems for their full-bore flow and minimal pressure drop. This guide helps engineers, plant managers, and procurement professionals understand the specific functions of each valve type, select the right valve, and optimise system performance.

Opening Scenario

Imagine an industrial chemical plant with a 12-inch pipeline that needs to isolate a section for maintenance due to pipeline corrosion. Selecting the wrong valve type could result in leakage, extended downtime, or premature valve failure. By choosing the correct isolation valve, such as a gate valve—a specific type of isolation valve—maintenance becomes safer, downtime is reduced, and system performance remains stable. Gate valves are ideal for large-diameter pipelines where full-bore flow and minimal pressure drop are essential. However, for applications requiring frequent operation or tight shut-off, such as in chemical processing or wastewater treatment plants, ball valves and globe valves may offer better performance due to their ability to handle high-frequency cycling and provide more precise flow control.

User Pain Points

Confusion Over Valve Selection

Engineers often struggle to select the correct isolation valve, with gate valves being a popular choice for full-bore applications, while other isolation valves like globe and Ball Valves are better suited for precise shut-off or high-frequency operation. Misunderstanding the function of each valve can result in operational inefficiencies or safety risks.

Pressure and Flow Limitations

Gate valves are specifically designed for full-bore applications, making them ideal for fully open or fully closed use. However, they are unsuitable for throttling due to the risk of turbulence, vibration, and accelerated wear, especially in high-frequency cycling applications, such as wastewater treatment plants, where flow regulation is crucial. In contrast, globe and ball valves excel in situations requiring precise flow control and frequent operation, such as in chemical processing systems or HVAC applications, where consistent cycling and tight shut-off are needed.

Maintenance and Longevity Concerns

Material selection and internal design significantly impact the longevity of isolation valves. Gate valves, particularly in corrosive or high-cycle environments, may require more frequent inspection and maintenance to prevent wear on seats and stems, typically requiring checks every 6-12 months in such conditions. On the other hand, Globe Valves and ball valves are often preferred in systems with frequent cycling, as they offer easier maintenance with replaceable components like seats and stems, minimizing downtime and reducing the frequency of inspections.

Solutions and Practical Recommendations

Understand the Application Requirements

-

Gate valves are ideal for full-open or full-close applications.

-

Isolation valves work best where frequent operation or precise shut-off is needed.

-

Consider temperature, pressure, and fluid type before selecting.

Match Valve Design to System Conditions

-

Flanged gate valves (a type of isolation valve) for large pipelines and higher pressures.

-

Threaded isolation valves for compact systems and moderate pressures.

-

Ensure material compatibility to prevent corrosion.

Implement Maintenance-Friendly Solutions

-

Use valves with replaceable seats and stems.

-

Schedule regular inspections, especially for chemical and seawater applications.

-

Document operation procedures to reduce human error.

Key Engineering Parameters to Evaluate

Before selecting an isolation valve or gate valve, engineers should clearly define:

-

Pressure rating (ANSI / PN class)

-

Operating temperature range

-

Process media (water, oil, steam, corrosive fluids)

- Operating frequency and duty cycle

-

Need for throttling or flow regulation

-

Leakage class and shut-off requirements

-

Actuation method and installation space

Case Examples

Case 1: Water Treatment Plant

Replacing worn-out isolation valves with modern threaded isolation valves, such as ball valves used for frequent shut-off, improved maintenance efficiency by 40%. These valves allowed quicker isolation during servicing, reduced leakage incidents, and minimised downtime in daily plant operations.

Case 2: Oil Refinery

Switching to flanged gate valves in a crude oil pipeline enabled unobstructed flow and significantly reduced pressure drop, optimizing throughput. While gate valves minimized pressure loss, for applications with more frequent cycling or where tighter shut-off is needed, ball and globe valves could also provide better performance during maintenance operations

Data, Scientific Comparison, and Material Analysis

| Feature | Gate Valve | Ball Valve | Globe Valve |

| Main Function | Full open/full close | Tight shut-off | Flow regulation |

| Throttling Capability | Not recommended | Limited | Excellent |

| Pressure Drop | Very low | Low | Medium to high |

| Operating Frequency | Low | High | High |

| Maintenance Complexity | Moderate | Low | Moderate |

Note: Gate valves are a specific type of isolation valve designed for full open or full closed service. While gate valves provide minimal pressure drop, other isolation valves—such as ball or globe valves—offer tighter shut-off and better suitability for frequent operation. Selecting the correct isolation valve type based on application conditions ensures long-term reliability and operational efficiency.

Market Trends and Industry Insights

-

In recent years, there has been a growing adoption of ball-type and threaded isolation valves in chemical and water treatment industries, driven by the need for frequent operation, compact installation, and reliable shut-off performance. With the increasing demand for energy efficiency and sustainability, engineers are selecting isolation valves based on factors like operating frequency, sealing performance, and lifecycle costs. The trend is also moving toward materials such as stainless steel and duplex alloys for their corrosion resistance and long-life performance

-

Engineers are increasingly selecting isolation valves based on operating frequency, sealing performance, and maintenance requirements, rather than relying solely on generic valve categories.

-

Industry trend towards corrosion-resistant materials and long-life designs, such as stainless steel or duplex alloys.

Usage and Selection Tips

-

Always verify pressure rating, temperature limits, and whether the application requires full-bore flow or frequent shut-off. Use gate valves as isolation valves in large-diameter pipelines where minimal pressure drop is critical, and select ball or globe isolation valves for applications requiring frequent operation or tighter sealing.

-

Consider installation space and piping layout.

-

Prefer valves with standardised dimensions for easy replacement.

-

Use valve types that support automation where required.

Summary and Call to Action (CTA)

Selecting the right type of isolation valve—including gate valves—ensures efficiency, safety, and system longevity.—is essential for efficiency, safety, and system longevity. By understanding operational requirements, material selection, and maintenance needs, plant managers can reduce downtime and optimise performance.

👉 Need professional advice on selecting the right valve for your system? Contact the Vcore engineering team today for tailored solutions.

FAQ

Q1: What is an isolation valve?

A: A Vcore isolation valve is a valve designed to completely shut off flow in a piping system for maintenance or safety purposes.

Q2: Is a gate valve an isolation valve?

A: Yes. A gate valve is a specific type of isolation valve intended for full open or full closed operation.

Q3: Can gate valves be used for throttling?

A: No. Throttling with a gate valve can cause vibration and accelerated wear, which is why gate valves should only be used for on/off operations.

Q4:Which isolation valve is best for frequent operation?

A: Ball valves or globe valves are more suitable for frequent cycling due to their precise flow control and ability to handle higher operating frequencies without excessive wear.

Q5:When should I use a gate valve instead of another isolation valve?

A: Gate valves are ideal for applications where the valve is either fully open or fully closed, especially in large pipelines requiring minimal pressure drop.

References

-

ASME B16.34 – Valves: Pressure–Temperature Ratings

-

API 600 – Steel Gate Valves

-

API 608 – Metal Ball Valves

-

ISO 5208 – Industrial Valves: Pressure Testing

- Valve World Magazine – Technical Articles on Valve Engineering