Quick Summary

Comparing tilting disc vs silent check valve is not simply a matter of preference. Each design behaves very differently under real operating conditions such as flow velocity, pressure fluctuation, and pump shutdown. At Vcore Valve, we often help engineers avoid costly mistakes by understanding how these check valves truly perform in service, not just on paper.

A Typical Engineering Conversation

“Both are check valves, right?”

“Yes—but one protects your pipeline, the other protects your sleep.”

Common User Pain Points

Water Hammer and Noise Issues

Incorrect valve selection can lead to severe pressure surges and system vibration.

Misunderstanding Closing Behaviour

Many users assume all check valves close the same way. They do not.

Overlooking Long-Term Operating Costs

Initial valve price often hides future maintenance and downtime expenses.

Practical Solutions from Vcore Valve

Match Valve Design to Flow Characteristics

Understand whether your system experiences frequent flow reversal.

Consider Dynamic Closing Speed

Faster is not always better—controlled closure matters.

Think Beyond Purchase Cost

Lifecycle performance outweighs initial savings.

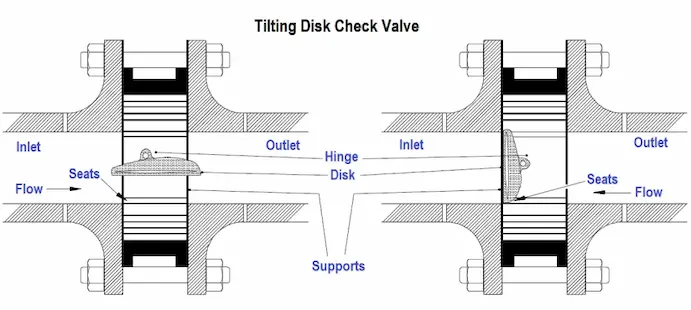

What Is a Tilting disc Check Valve?

A tilting disc check valve uses a pivoting disc mounted on an offset hinge. When flow moves forward, the disc tilts open. When flow slows or reverses, gravity and backflow force close the disc smoothly.

Key Characteristics:

-

Low pressure drop

-

Suitable for large diameter pipelines

-

Effective in steady flow systems

At Vcore Valve, tilting disc designs are widely used in power generation and large-scale water systems.

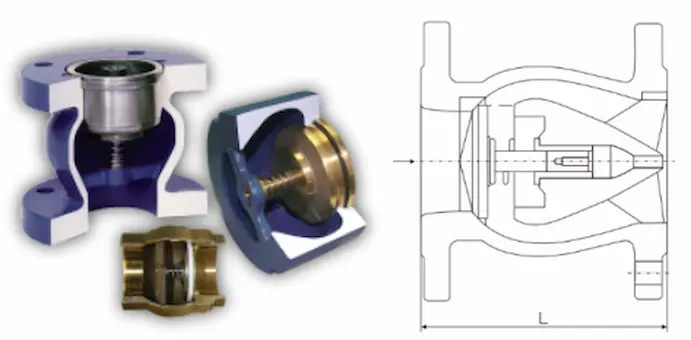

What Is a Silent Check Valve?

A silent check valve, also known as a non-slam check valve, uses a spring-assisted disc or piston. The valve closes automatically before reverse flow occurs, significantly reducing noise and water hammer.

Key Characteristics:

-

Spring-assisted closure

-

Compact design

-

Excellent for pump discharge lines

Tilting Disc vs Silent Check Valve Structural Design Comparison

| Feature | Tilting disc Check Valve | Silent Check Valve |

|---|---|---|

| Closing mechanism | Gravity + backflow | Spring-assisted |

| Noise level | Moderate | Very low |

| Pressure drop | Low | Slightly higher |

| Water hammer control | Good | Excellent |

| Installation orientation | Horizontal preferred | Flexible |

Case Study: Pump Station Retrofit

A municipal pump station suffered repeated pipe stress failures.

Original setup:

Tilting disc check valve installed downstream of pumps.

Problem:

Rapid pump shutdown caused reverse flow shock.

Solution:

Replacing with Vcore Valve silent check valves eliminated pressure spikes and reduced maintenance incidents by over 60%.

Engineering and Data-Based Comparison

Studies show:

-

Silent check valves reduce water hammer pressure by up to 80%

-

Tilting disc check valves offer 30–40% lower pressure loss under steady flow

-

Improper valve selection contributes to nearly 35% of pump-related failures

Industry Trends and Market Insights

-

Increasing adoption of silent check valves in urban water systems

-

Continued preference for tilting disc designs in large-diameter pipelines

-

Growing emphasis on noise reduction regulations

-

Lifecycle cost analysis becoming standard in valve procurement

Selection and Usage Recommendations

Choose a tilting disc check valve when:

-

Flow is stable and continuous

-

Large diameter pipelines are involved

-

Low pressure loss is critical

Choose a silent check valve when:

-

Pump systems are sensitive to backflow

-

Noise and vibration must be minimised

-

Space is limited

Conclusion

There is no universal “best” check valve—only the right one for your system.

At Vcore Valve, we engineer both tilting disc check valves and silent check valves with application-specific guidance to ensure safe, quiet, and efficient pipeline operation.

👉 Contact Vcore Valve to receive expert support on check valve selection and system optimisation.

FAQs

Q1: Are silent check valves always better than tilting disc types?

No. Each design serves different operating conditions.

Q2: Which valve is better for preventing water hammer?

Silent check valves provide superior water hammer control.

Q3: Do tilting disc check valves require more space?

Yes, they typically need more installation clearance.

Q4: Can silent check valves be installed vertically?

Many designs allow vertical installation, depending on model.

Q5: Which valve has a longer service life?

Both can perform well if correctly selected and maintained.

Q6: Does Vcore Valve offer custom check valve solutions?

Yes, based on system parameters and standards.